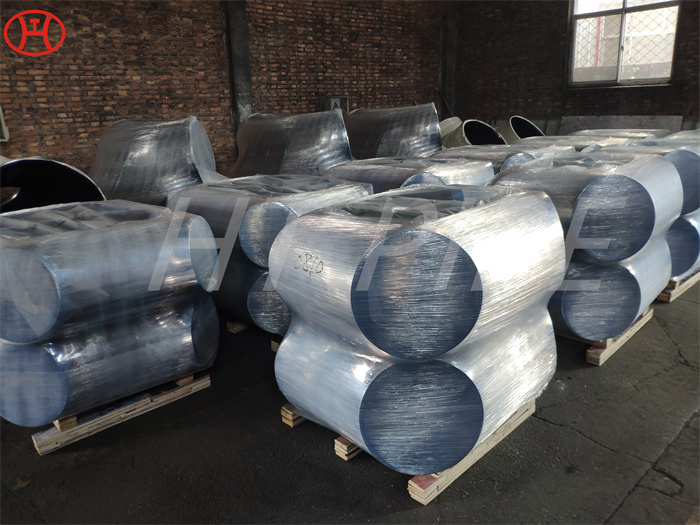

Nickel alloy steel pipe fittings elbows

Nickel alloys pipe fittings are metals made from combining nickel as the primary element with another material. It merges two materials to deliver more desirable features, such as higher strength or corrosion-resistance. Because of its unique properties, it’s used in a variety of equipment spanning multiple industries.

ASTM B366 UNS N08825 Buttweld Elbow and Nickel Alloy 825 Pipe Tee Manufacturer in China.

Inconel 825, has all properties one expects from a nickel alloy. With a chemical makeup similar to alloy 800, the Incoloy 825 Threaded Forged Fittings and Socketweld Branch outlets exhibit resistance to an aqueous medium like the former alloy. Yet, the addition of molybdenum with both copper and titanium improves the resistance of the material to several aqueous media. Therefore the DIN 2.4858 Pipe Reducer and Alloy 825 Long Radius Elbows are well suited to ferry across corrosive fluid media across a pipeline in a piping system. With a very stable austenite structure and a high content of nickel, as is the case with most Inconel alloys, Incoloy 825 elbow is made of an alloy that possesses sufficient resistance to chloride ion stress related corrosion cracking.

The addition of high content of chromium in Incoloy 825 elbow aids in resistance to oxidative conditions. Which is why the Inconel 825 Weld Fittings have great resistance to highly corrosive, yet oxidative solutions such as nitrates, nitric acid solutions, as well as oxidizing salts. Alloy 825 is stabilized by the addition of titanium. By the addition of a stabilizing agent like titanium, the Incoloy 825 Pipe Fittings remain free from intergranular corrosion that could occur in the HAZ or heat affected weld zone. Nickel alloy UNS N08825 Buttweld Elbow is resistant to acids such as sulphuric acid and phosphoric acid. Therefore, keeping its high mechanical strength and corrosion resistance properties in mind, most suppliers recommend the use of Alloy 825 Tee for the production of sulfuric acid.

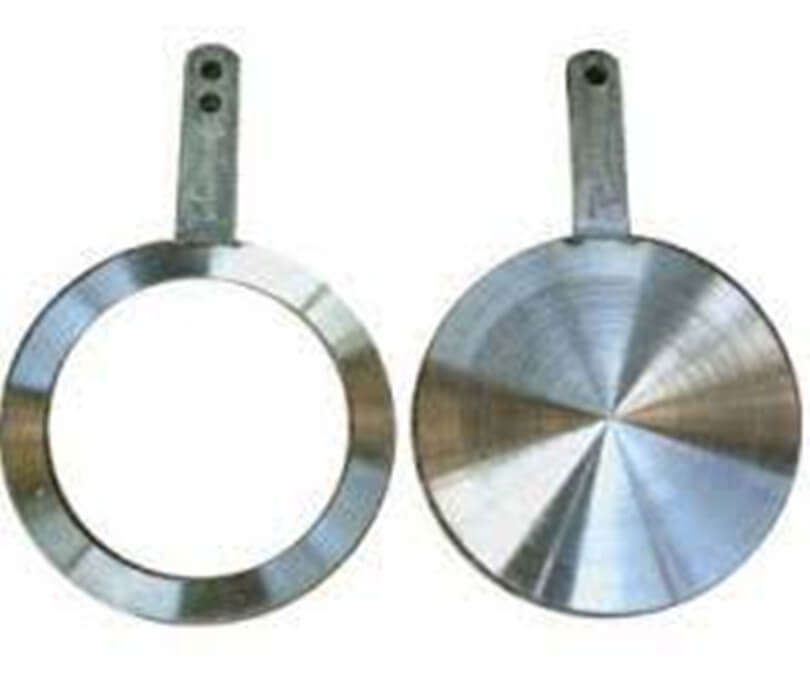

Incoloy 825 Pipe Fittings Material Specification

| Grade | 825 |

| Specifications | ASTM B366/ ASME SB366 |

| Size Ranges | ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. |

| Dimension | ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10 |

| Bending Radius | Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D |

| Types | Welded | Seamless | Fabricated |

| Size Range | Seamless Butt-Weld Fitting: From 1/2″ – 10″ |

| Welded ButtWeld Fitting: From 1/2″ – 48″ | |

| Thickness of Fitting | SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 |

| Process of Manufacturing | Push, Press, Cast, Forge. |