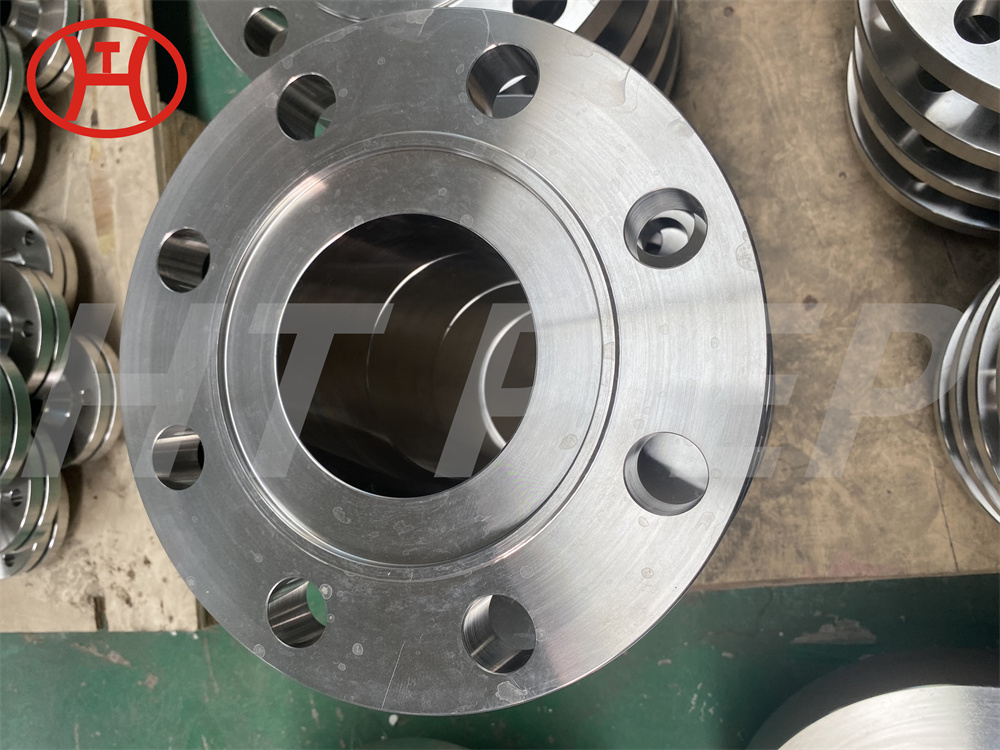

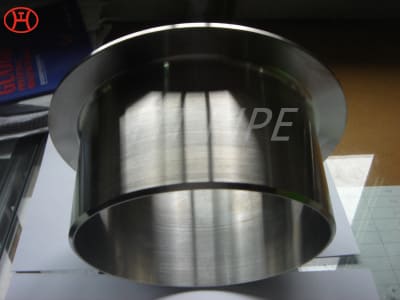

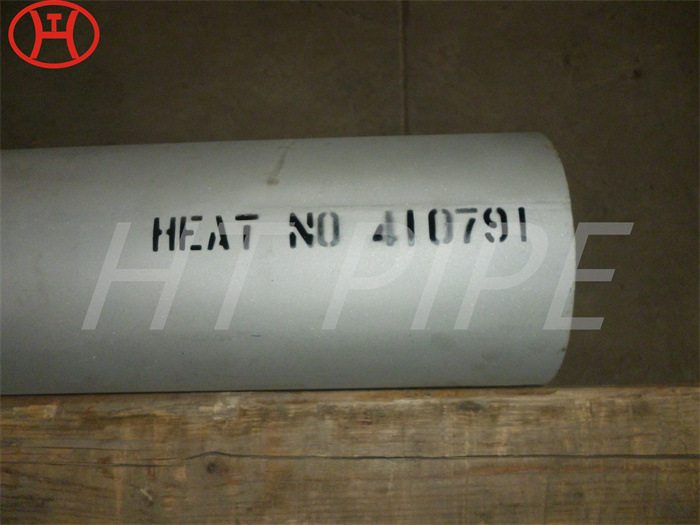

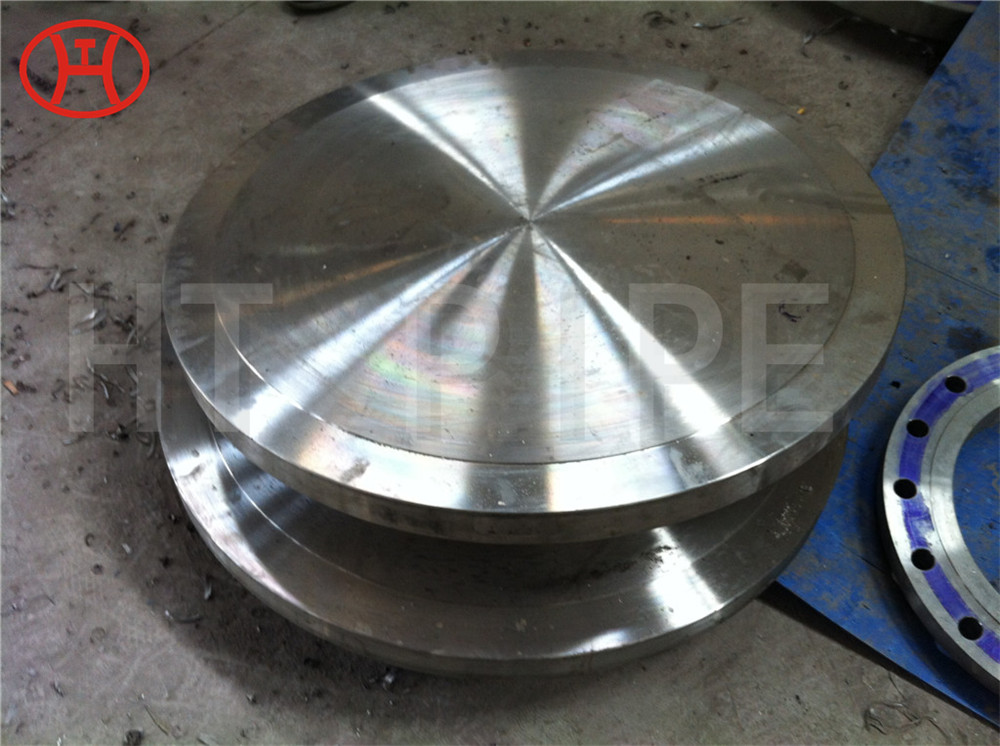

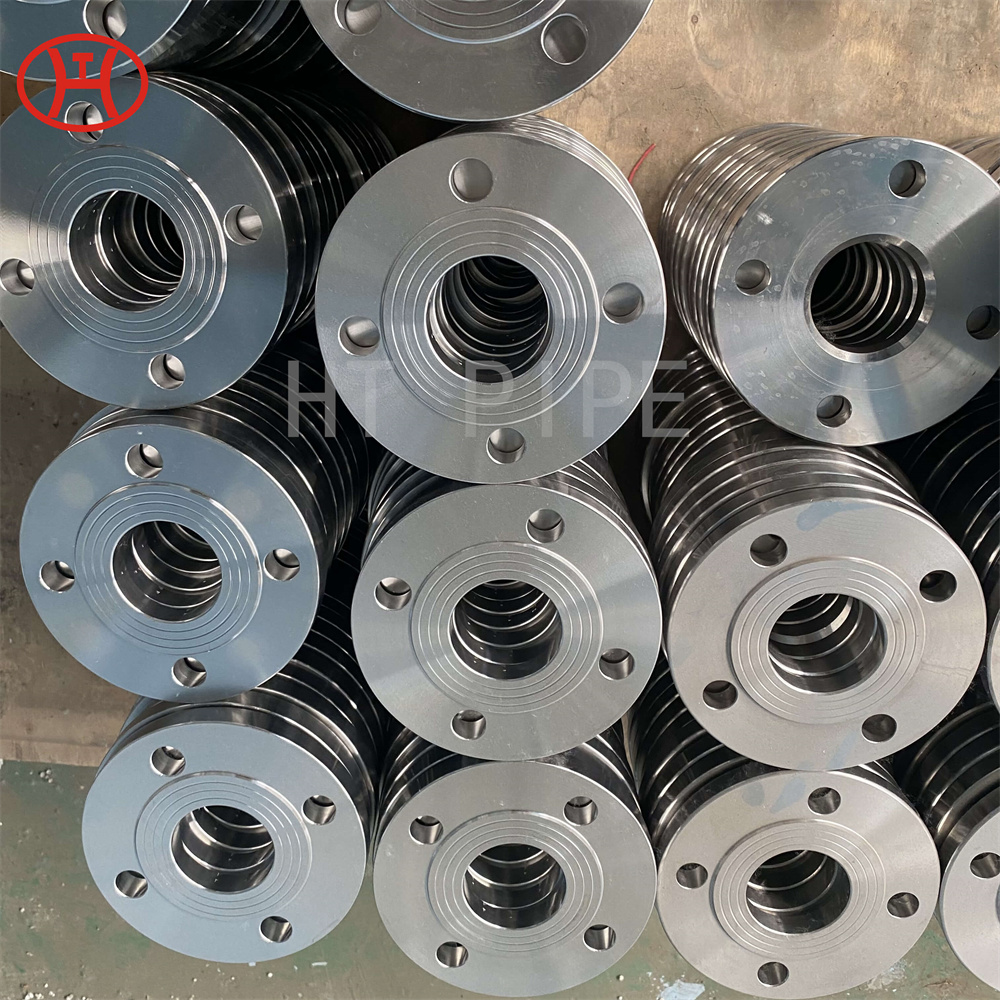

normalizing of 316L S31603 Z3CND17-11-02 stainless steel flange

Normalizing is a heat treatment process used to make metals more ductile and ductile after a thermal or mechanical hardening process. Normalizing involves heating the material to a high temperature and then exposing it to room temperature air after heating, allowing it to cool to room temperature. This heating and slow cooling alters the metal’s microstructure, reducing its hardness and increasing its ductility.

Normalizing is often done because another process intentionally or unintentionally reduces ductility and increases hardness. Normalizing is used because it causes the microstructure to reform into a more ductile structure. This is important because it makes the metal more formable, easier to machine, and reduces residual stresses in the material that can lead to unexpected failures.