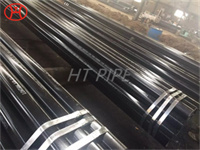

Alloy p91 pipe seamless tube

Astm a335 P91 pipe is a seamless pipe for high temperature applications. These pipes are made of ferritic alloy steel. Chemically speaking, a335 P91 welded pipe contains elements such as molybdenum (Mo) and chromium added to the alloy. The tensile strength of sa335 grade P91 pipe increases when molybdenum and chromium are added to the alloy. The tensile strength of a335 grade P91 pipe is 415 Mpa, while its yield strength is 205 Mpa. Pipe elongation ranges from 20% to 30%.

Alloy Steel P91 is considered unique because of additional features for advanced chromium-molybdenum pipes with tube options, including 9 CrMoV, boron-doped materials, and tungsten. These grades are in the 92–122, 23–24, and higher ranges. The CSEF steels are distinct, according to P(T)91. With a higher chromium content, steel is a quite different substance widely employed in various applications. Therefore it primarily calls for primary usage with more excellent care.

P91 is a chrome moly alloy metal that contains excellent strength and temperature resistance. Alloy p91 pipe is designed for enhanced creep strength, making it a creep strength enhanced ferritic (CSEF). The manufacturing procedure of ASME SA335 grade P91 pipe starts with its forming by either cold drawing or hot finished followed by heat treatment. The heat treatment begins with the process of normalizing the pipe at 1050 °C followed by cooling down by air at 200 °C and then tempering at about 760 °C. This metal is made by normalizing at 1050 °C, air cooling to 200 °C, and then tempered through heating to 760 °C.

The ferritic alloy steel A335/SA335 P91 has extremely high strength characteristics that do not degrade over time and are creep-resistant. Alloy p91 pipe is also referred to as chrome moly pipe or 9 Cr 1 Mo steel depending on its chemical makeup.

Grade P91 is far stronger than its predecessors, the T22 or P22 Grade, and can withstand temperatures up to 600 °C. Manufacturers can raise the operating temperature to a greater level, increasing efficiency and resulting in a thermal fatigue life that is almost ten times higher. Additionally, thinner elements can be designed since oxidation temperature limitations are higher. Alloy p91 pipe generally permits a minimum 2-to-1 reduction in wall thickness. A thinner wall utilizes less filler metal, shorter welding time, and lighter hanger loads. These advantages are made feasible by the steel’s high chromium concentration. Grade 91 has 9% chromium and 1% molybdenum, while the next-best P22 Grade has 2.5% chromium.