Pipe fitting made in china ASTM A234 carbon steel pipe fittings

Knowing the finish of these steels can be helpful if your pipes are visible and appearance is on the list of considerations. Stainless steel is usually glossy and can retain that gloss if exposed to weather and other factors. Carbon steel, on the other hand, is darker in color and usually has a matte finish when painted. Unfortunately, it can also rust and look bad if left exposed. Galvanizing is also an option.

ASTM A234 Carbon and Alloy Steel Pipe Fittings

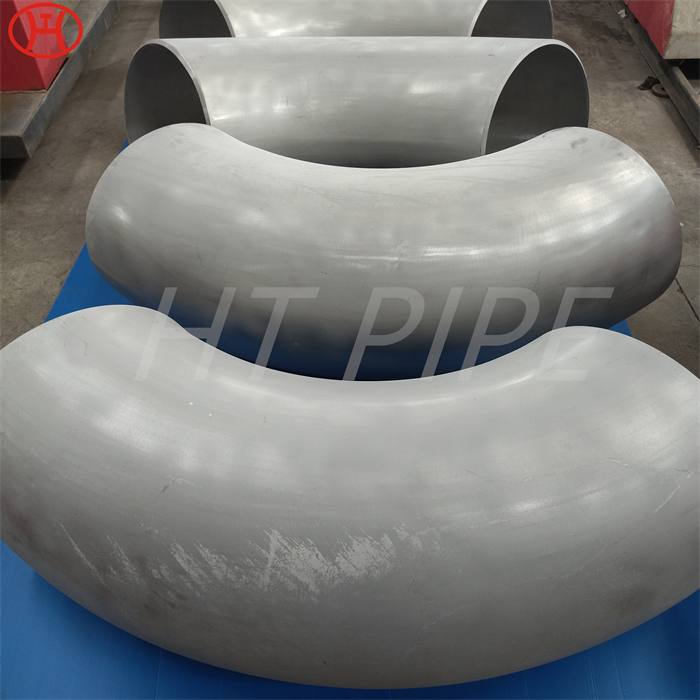

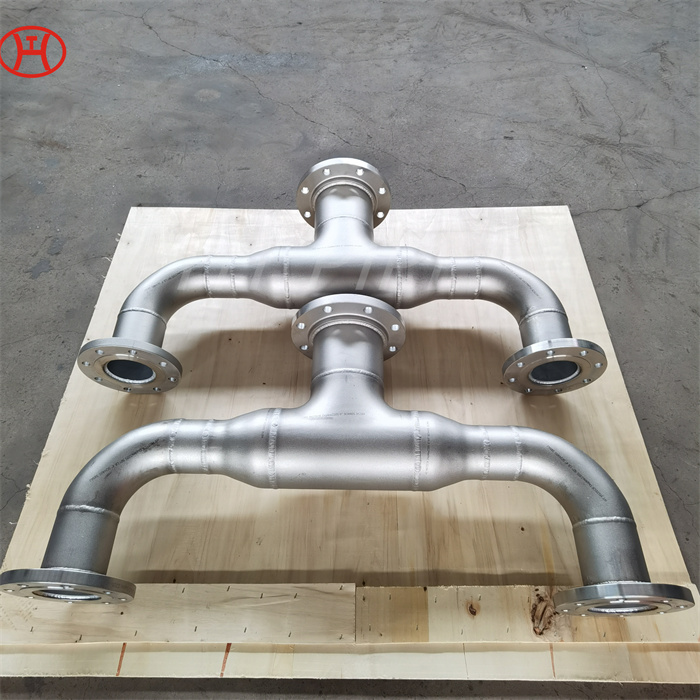

ASTM A234 standard steel pipe fittings have been widely applied in pipeline systems, it includes carbon and alloy steel material. A234 Pipe Fittings are made of carbon or alloy steel pipe, plates, profiles, to a certain shape that could make a function (Change the fluids direction or rate) in pipeline systems. Mostly these A234 Pipe Fittings includes steel elbow (45 or 90 degree bend), tee, reducer (concentric or eccentric reducer), cross, caps, nipple, flanges, gasket, studs and etc. For industrial purposes, in pipeline systems usually we need to change the transmission direction; Adjust fluids (oil and gas, water, slurry) flow rate; Open or close the pipelines, etc. So to complete these activities, steel pipe fittings will be applied.

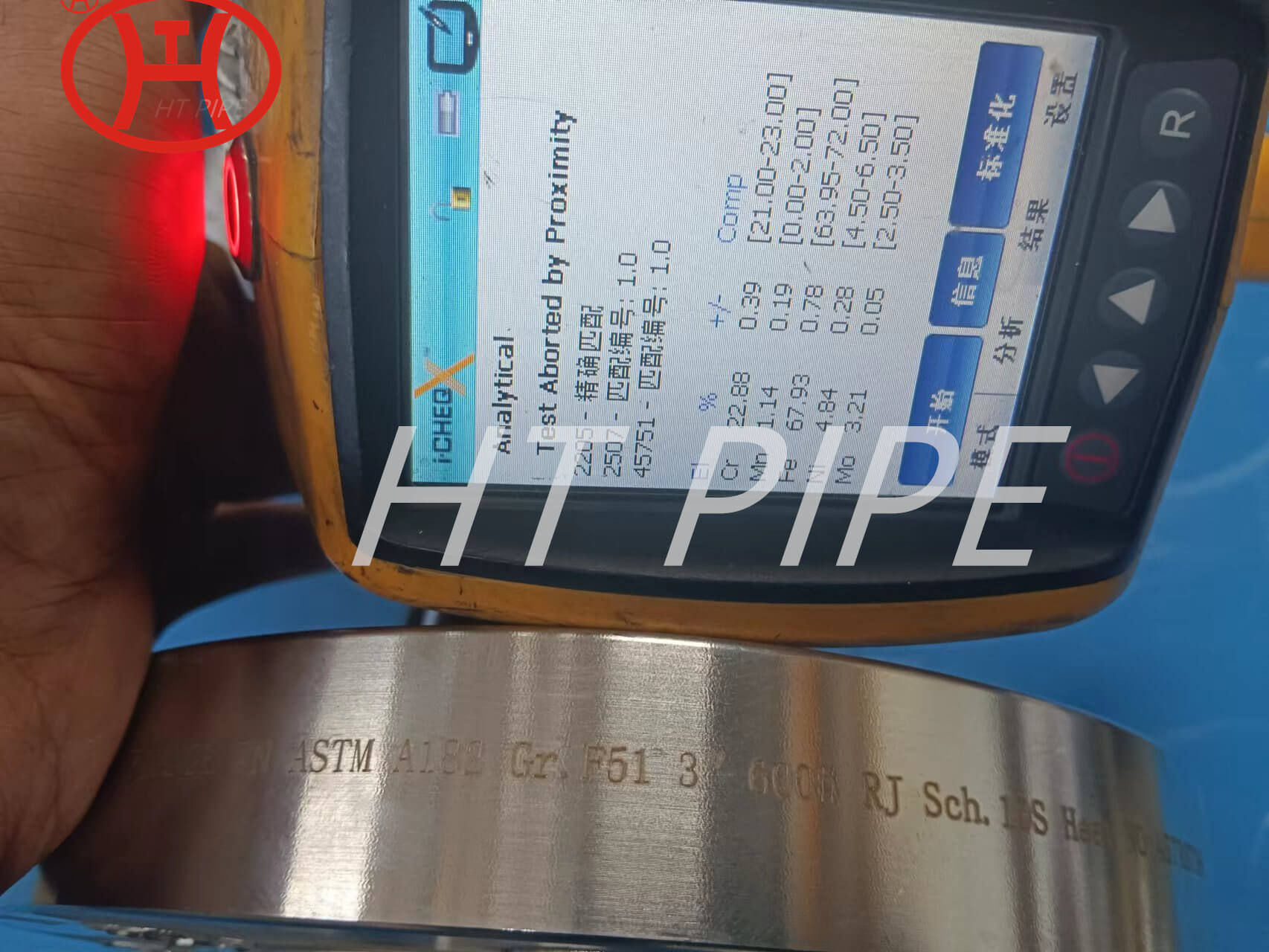

ASTM A234 is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high temperature services. It covers steel fittings of seamless and welded types. Steel Pipe fittings are applied in pressure pipelines and in pressure vessel fabrications. These ASTM B16.9 fittings material consist of killed steel, forgings, bars, plates, seamless or HFW (fusion welded) pipe products, with filler metal added. ASTM A234 includes wrought carbon steel and alloy steel fittings of seamless and welded construction covered by the latest revision of ASTM B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97. etc. As we know, ASTM A234 steel pipe fittings are used in pressure piping and in pressure vessel fabrication, for services at moderate and elevated temperatures. The carbon steel pipe fittings in this standard consist of killed steel, forgings, bars, plates, seamless or fusion-welded tubular products with filler metal added. In this standard it covers the specification of elbows, tees, reducers, caps and cross, it usually adopt butt welding ends.

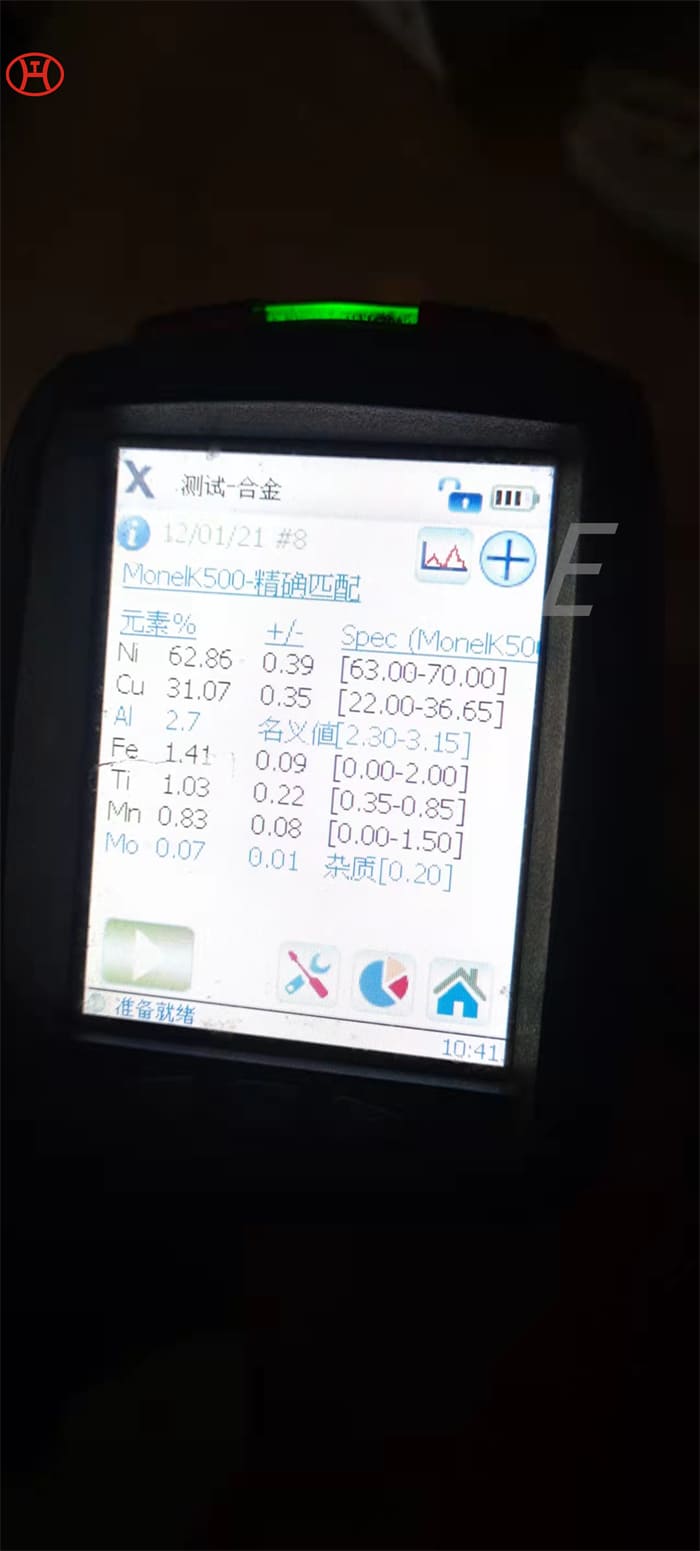

| Element | Content, % | |

| ASTM A234 WPB | ASTM A234 WPC | |

| Carbon [C] | ≤0.30 | ≤0.35 |

| Manganese [Mn] | 0.29-1.06 | 0.29-1.06 |

| Phosphorus [P] | ≤0.050 | ≤0.050 |

| Sulfur [S] | ≤0.058 | ≤0.058 |

| Silicon [Si] | ≥0.10 | ≥0.10 |

| Chromium [Cr] | ≤0.40 | ≤0.40 |

| Molybdenum [Mo] | ≤0.15 | ≤0.15 |

| Nickel [Ni] | ≤0.40 | ≤0.40 |

| Copper [Cu] | ≤0.40 | ≤0.40 |

| Vanadium [V] | ≤0.08 | ≤0.08 |

*The Carbon Equivalent [C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15] shall be no greater than 0.50 and shall be reported on MTC.