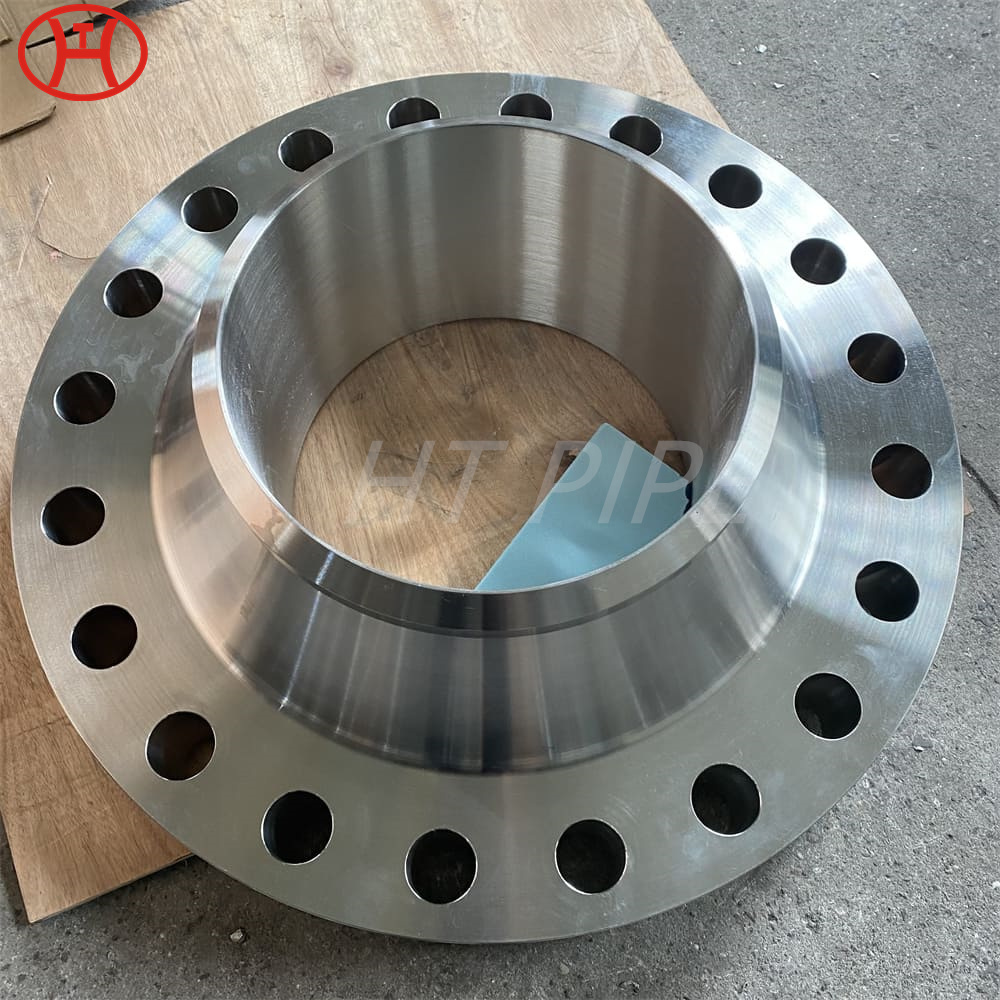

Pipe Spools Fabrication Inconel 718 2.4668 pipe with flanges

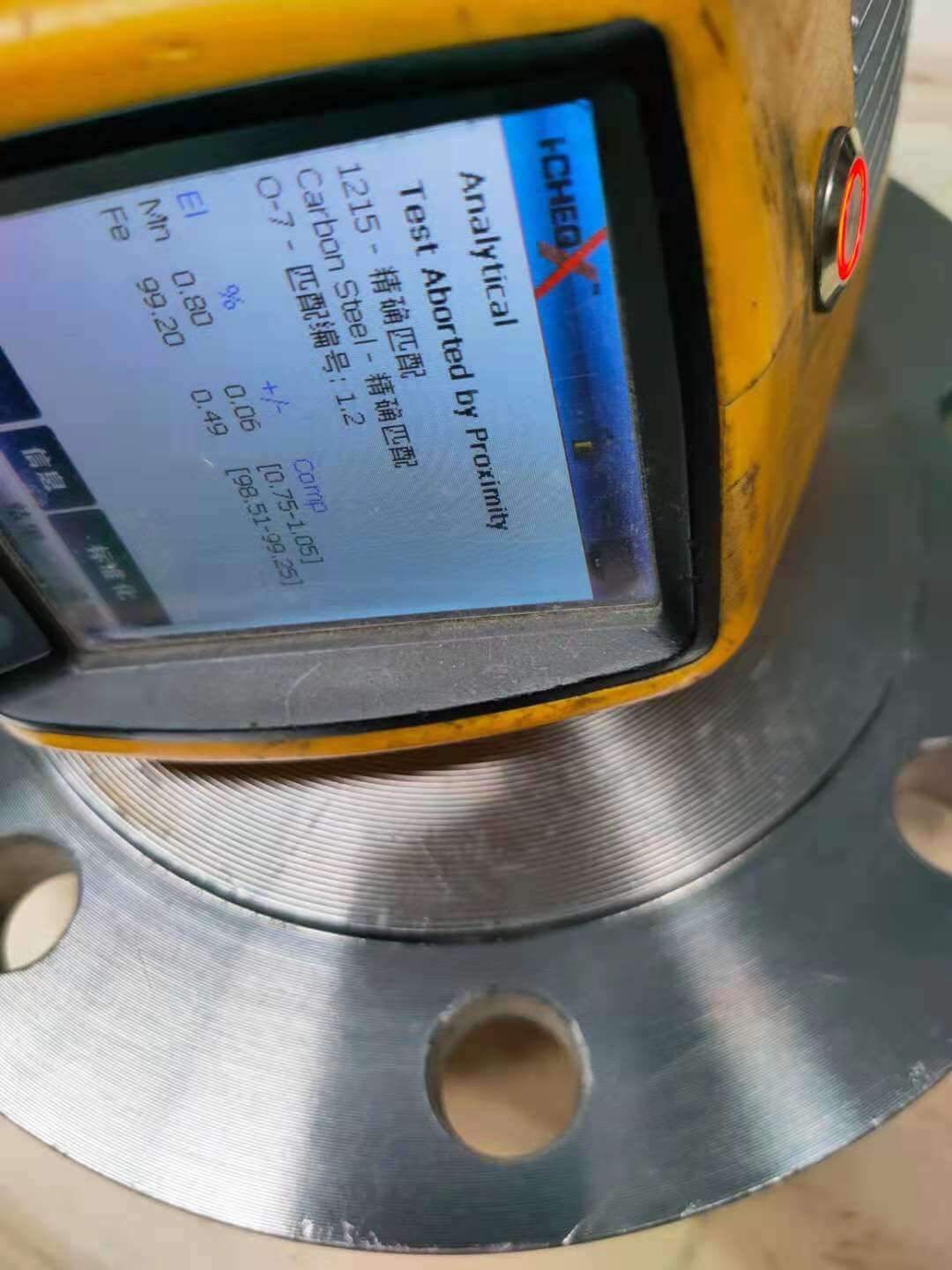

Inconel 718 tubing is a high performance nickel alloy used in sour oil and gas fields. Inconel 718 tube hardened nickel-based alloys and cold-worked solid nickel-based alloys offer many advantages including high strength, toughness, low magnetic permeability, and excellent corrosion resistance.

Inconel 718 tube has proven to be a valuable and versatile material, capable of solving a wide variety of design and application problems. Inconel 718 tubing is resistant to low temperature aggressive corrosive environments as well as harsh high temperature environments. Alloy 718 ASTM B163 is an austenitic nickel base superalloy. Alloy 718 Nickel Tubing exhibits excellent high yield tensile and creep rupture properties at temperatures up to 1300¡ãF and oxidation resistance at temperatures up to 1800¡ãF. Alloy 718 W. Nr 2.4668 is used in applications requiring high strength such as jet engine parts and high speed airframe parts such as wheels, buckets, spacers and high temperature bolts and fasteners.

nconel 718 Pipes is a heat and corrosion resistant nickel alloy powder optimized for system processing. Inconel 718 tubing is still considered the material of choice for most aircraft engine components operating at temperatures below 1200 degrees Fahrenheit (650 degrees Celsius). Modern aircraft engines made from Inconel 718 tubes are more reliable than their predecessors due to huge advances in technology.