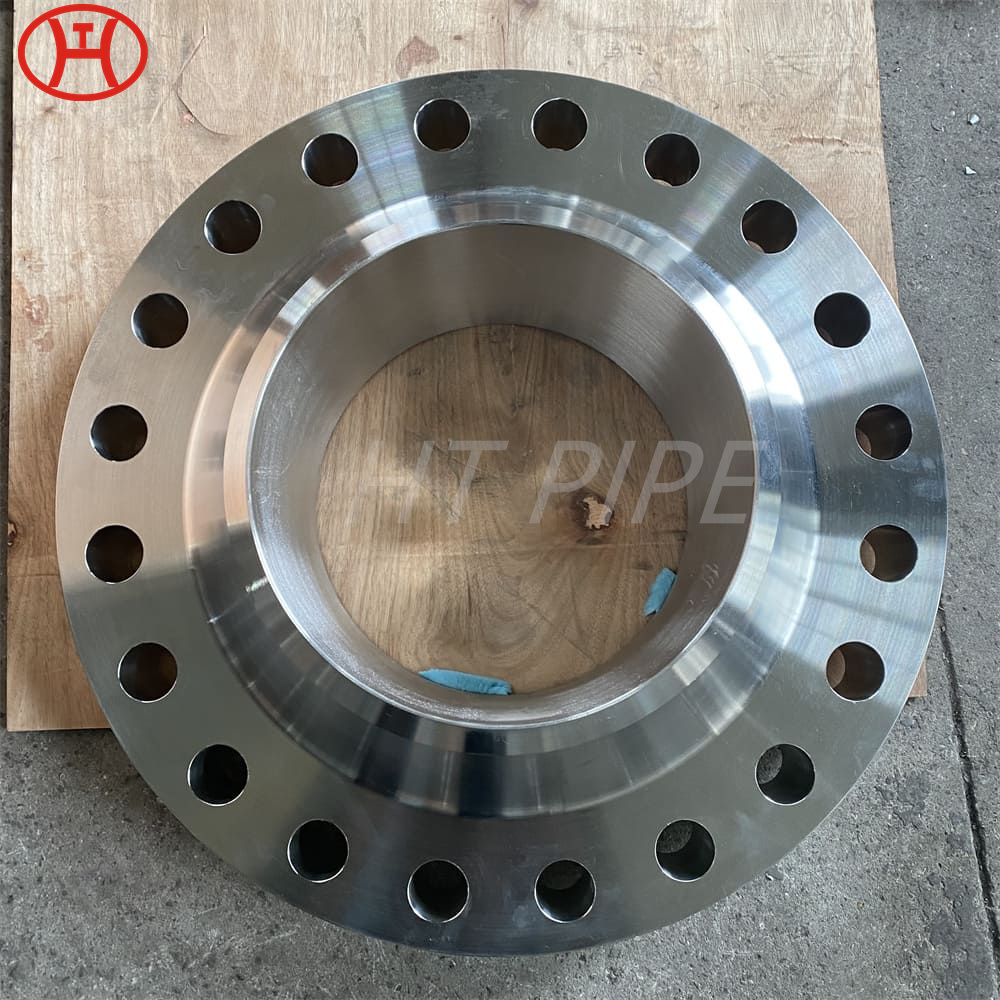

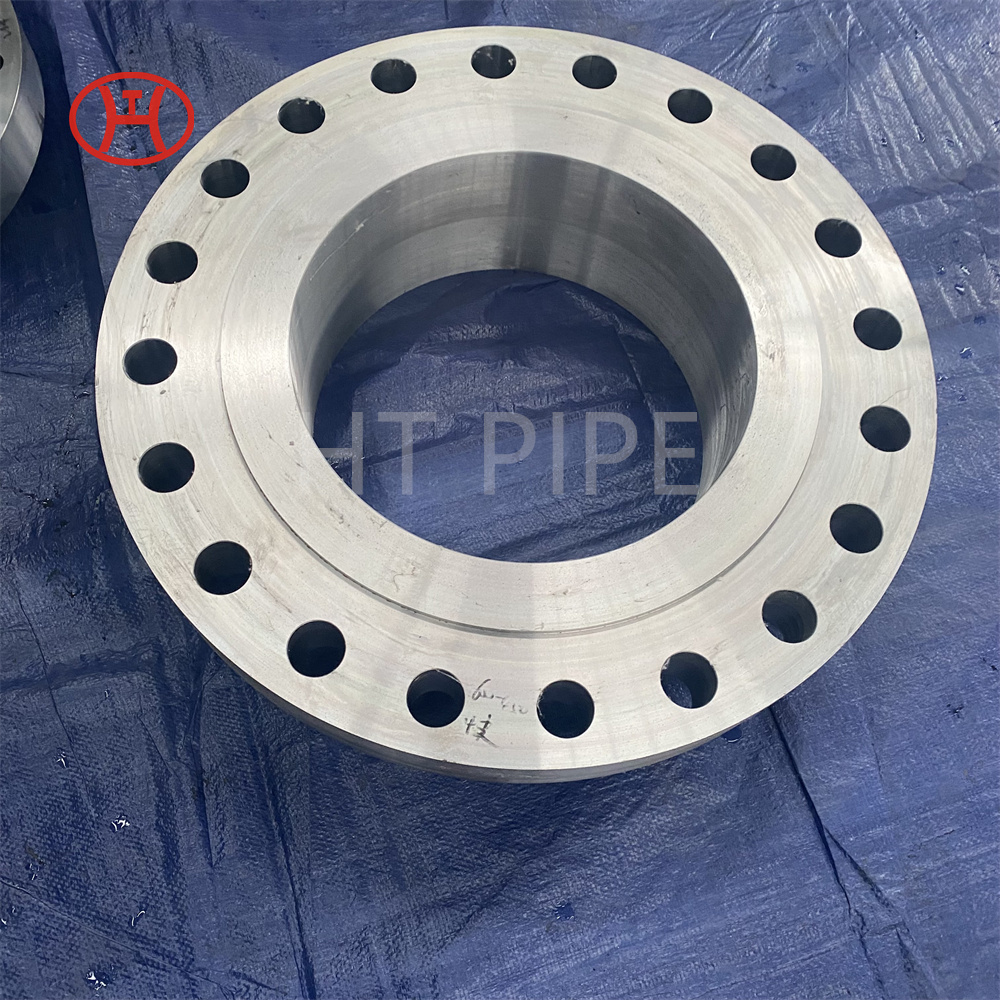

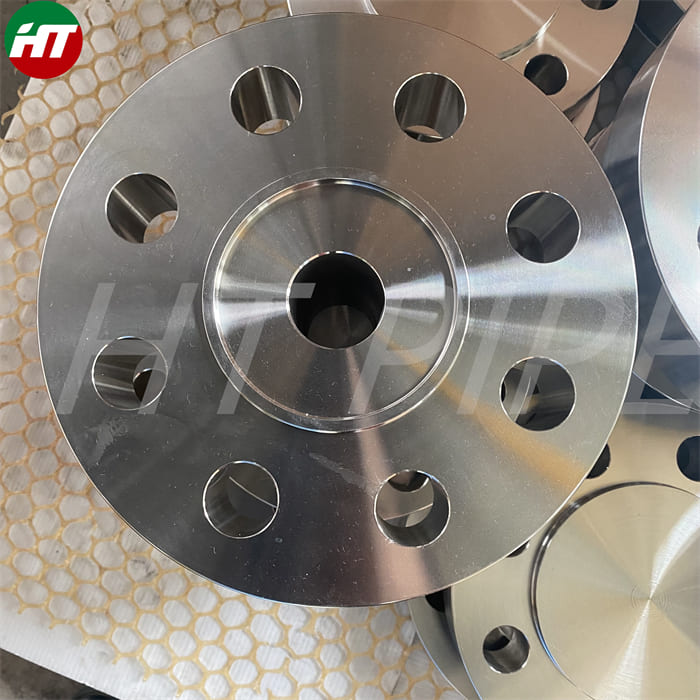

Pipe Spools Fabrication Inconel 718 alloy WERKSTOFF NR.2.4668 pipe with flanges

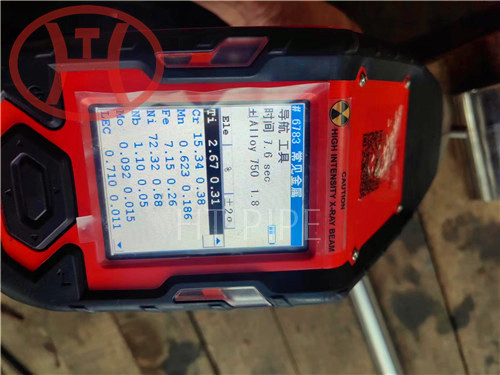

Inconel 718 Welded Pipe is a nickel-chromium-molybdenum alloy designed to resist a variety of severe corrosive environments, pitting and crevice corrosion. Inconel 718 EFW pipe is a nickel-chromium alloy that is precipitation hardenable with high creep rupture strength at elevated temperatures up to approximately 1300 degrees Fahrenheit (700 degrees Celsius). Inconel 718 ERW tube has excellent mechanical properties at high and low temperatures.

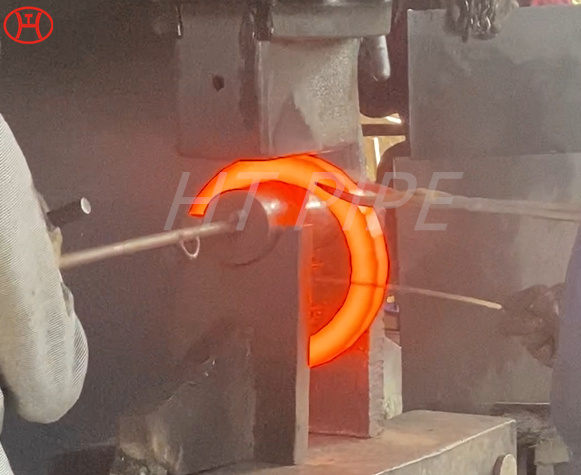

Since Inconel 718 is a high strength alloy, UNS N07718 pipe can withstand temperatures up to about 1300¡ãF. A major hurdle in turbine manufacturing is the selection of suitable materials that help combat creep. In this case, Inconel 718 is an ideal metal that not only has good tensile properties, but also good fatigue properties, as well as higher creep and rupture strengths.

Inconel 718 Round Tube We also offer our customers different sizes and shapes. Inconel 718 Pipes is an austenitic nickel-based superalloy that can be used in a variety of conditions with high strength and excellent corrosion resistance. Inconel 718 Pipes is a heat and corrosion resistant nickel alloy powder optimized for system processing. Inconel 718 tubing is still considered the material of choice for most aircraft engine components operating at temperatures below 1200 degrees Fahrenheit (650 degrees Celsius).