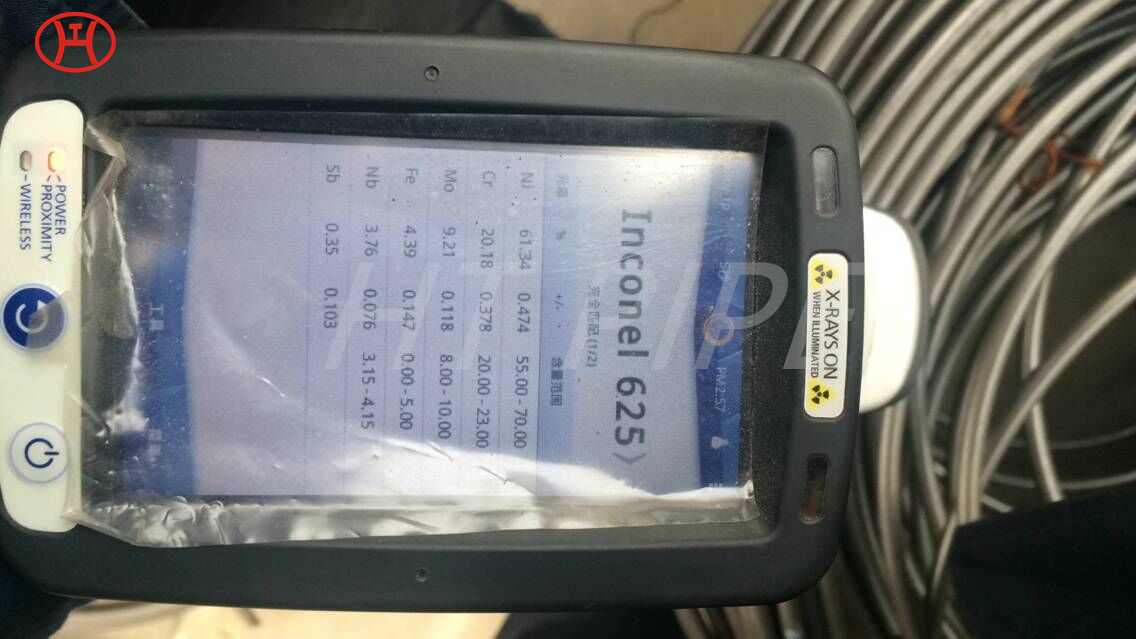

PMI for Inconel 625 wire PMI testing

Nickel Alloy Inconel 625 | UNS# N06250 is a nickel-based superalloy with high strength properties, high temperature resistance, and significant oxidation and corrosion protection. Nickel alloy Inconel 625 shows the ability to withstand high stress environments and has excellent machinability.

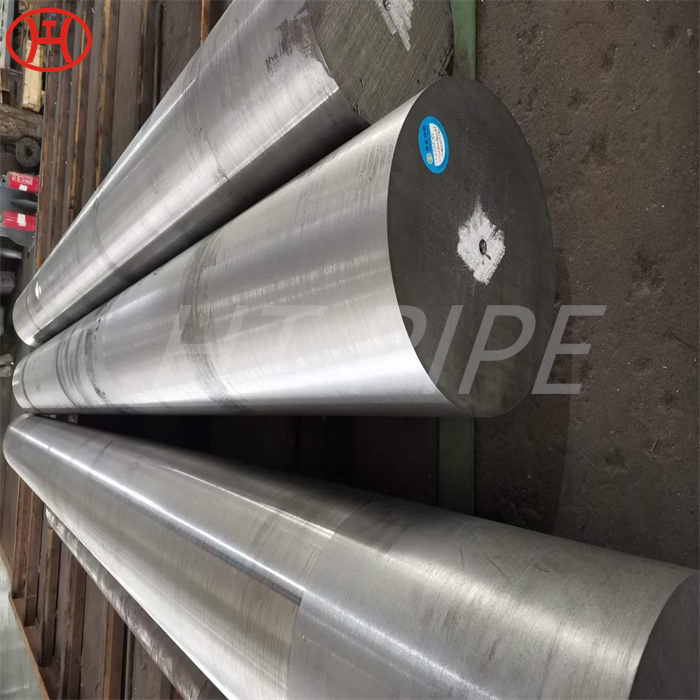

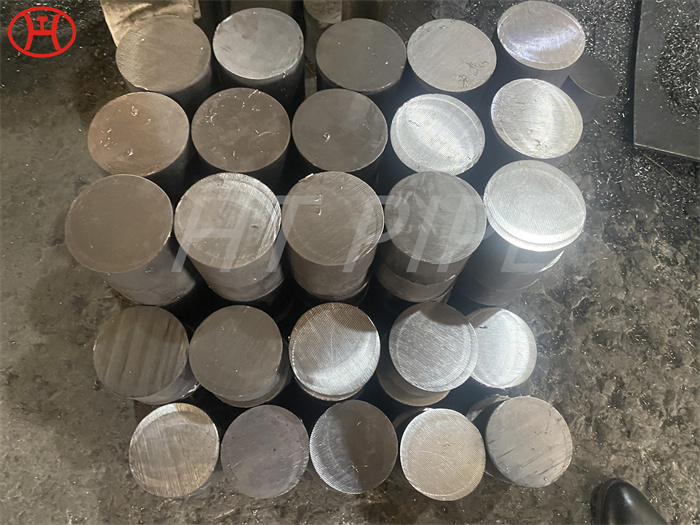

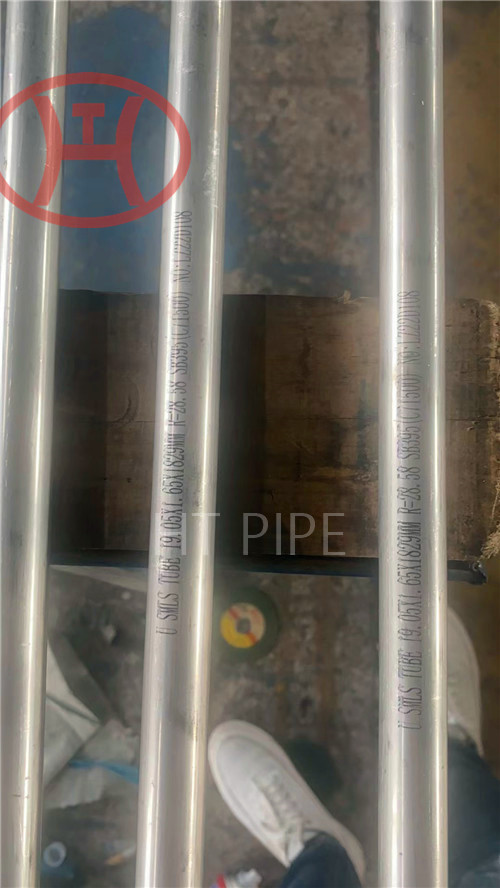

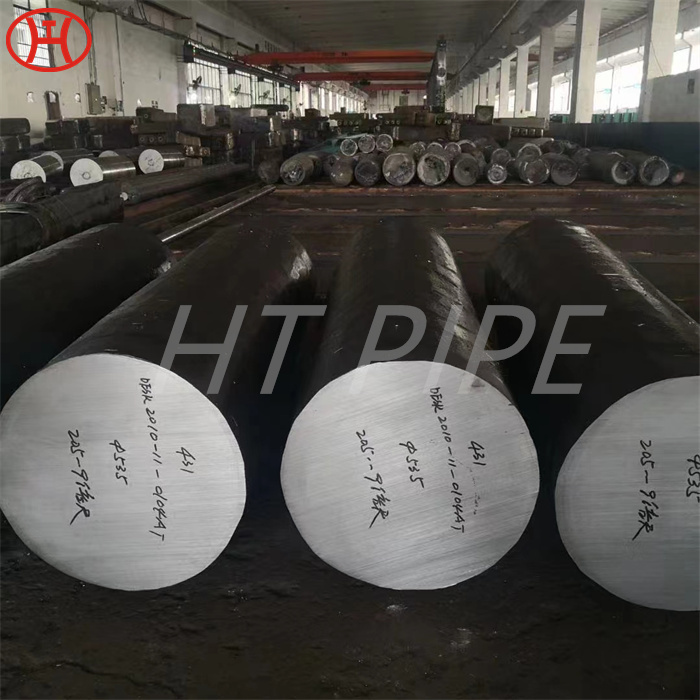

Nickel Alloy 625 bar, rod and wire is used for its high strength, ease of fabrication (including joining) and excellent corrosion resistance. The operating temperature range is from cryogenic to 1800¡ãF (982¡ãC). Alloy 625 derives its strength from the hardening of its nickel-chromium matrix by molybdenum and niobium, so precipitation hardening is not required. This unique composition also gives the product excellent resistance to a variety of severe corrosive conditions and high temperature effects such as oxidation and carburization. The properties of Alloy 625 make it an excellent choice for seawater, aerospace and chemical processing applications. At the same time, Inconel 625’s refractory metal and alloy combination exhibits uniform performance from low temperatures to over 1000 degrees Celsius/2000 degrees Fahrenheit. Other performance characteristics include resistance to oxidation and oxidation, stability during welding, resistance to chloride stress and corrosion cracking, and excellent fatigue strength.