Russia seamless steel pipe

Seamless steel pipes have a hollow section and are used in large quantities as pipelines for transporting fluids, such as pipelines for transporting oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, steel pipe is lighter in flexural and torsional strength and is an economical section steel.

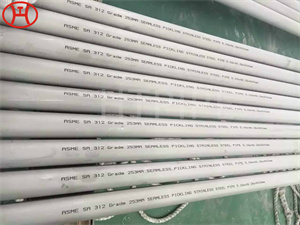

Seamless Steel Pipe/Tube (SMLS Pipe/Tube), Seamless Precision Pipe, MS Large Diameter Seamless Pipe, Seamless steel pipe size

The seamless steel pipe is perforated by the whole round steel, and the steel pipe without weld on the surface is called seamless steel pipe. According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and pipe jacking. According to the cross-sectional shape, seamless steel pipes are divided into two types: round and special-shaped. Special-shaped tubes include square tubes, elliptical tubes, triangular tubes, hexagonal tubes, melon seed tubes, star tubes, finned tubes, etc. The maximum diameter is 900mm and the minimum diameter is 4mm. According to different uses, there are thick-walled seamless steel pipes and thin-walled seamless steel pipes.

In addition, seamless steel pipes have better pressure bearing capacity and higher strength than ERW welded steel pipes. Therefore, it is widely used in high-pressure equipment, thermal power, boilers and other industries. Generally, the weld of welded steel pipe is the weak link, and the quality affects the overall performance.

Manufacturing Process:

Billets and coils are delivered to the pipe mill ready to be made into carbon steel pipe. Depending on the capabilities of the pipe mill and the end use of the final product, the casts will be formed into pipe by means of four distinct different manufacturing.Seamless carbon steel pipe has, as its name implies, no longitudinal weld seam. It is, in essence, one solid homogeneous piece of steel. A solid billet is simply heated and then stretched over a series of mandrels until the pipe has achieved its desired diameter and wall thickness.

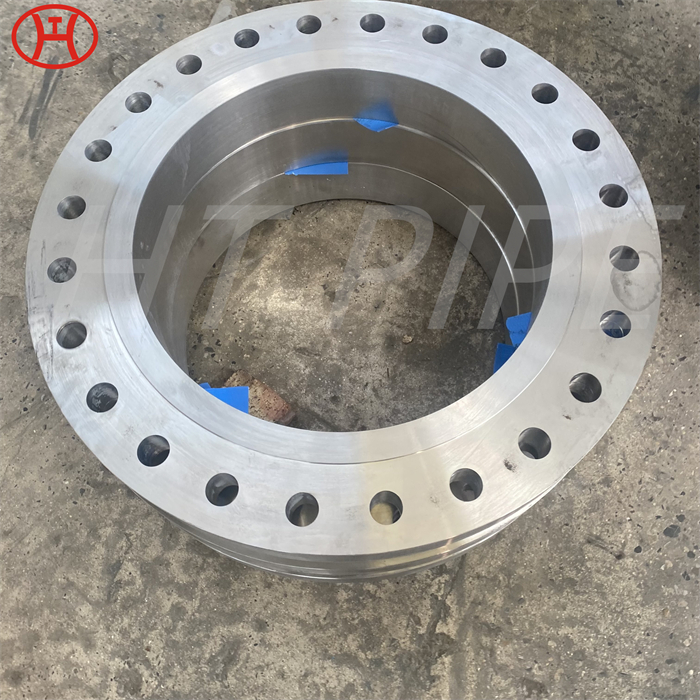

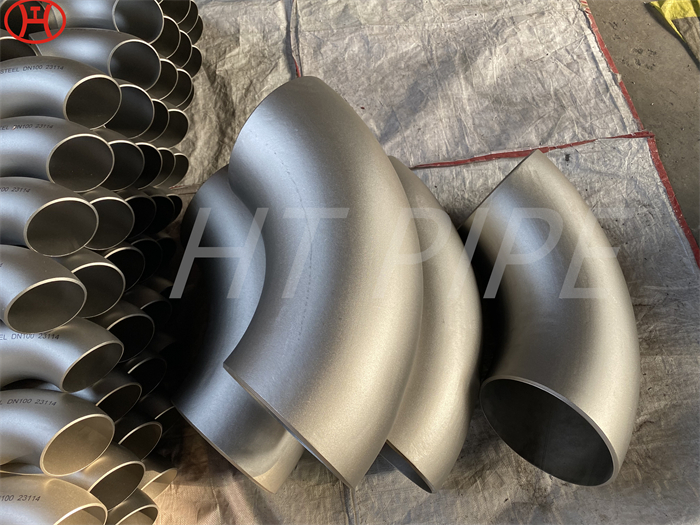

Seamless steel pipes are widely used.

1. General-purpose seamless steel pipes are rolled by ordinary carbon structural steel, low-alloy structural steel or alloy structural steel, with the largest output, and are mainly used as pipelines or structural parts for conveying fluids.

2. According to different purposes, it can be supplied in three categories:

a. Supply according to chemical composition and mechanical properties;

b. According to mechanical performance;

c. According to the water pressure test supply. Steel pipes supplied according to categories a and b. if used to withstand liquid pressure, shall also be subjected to a hydraulic test.

Is seamless pipe stronger than welded pipe?

Seamless steel pipe has better pressure capacity, strength is higher than ERW welded steel pipe. So it is widely applied in high pressure equipment, and thermal, boiler industries. Generally the welding seam of the welded steel pipe is the weak point, the quality affect overall performance.

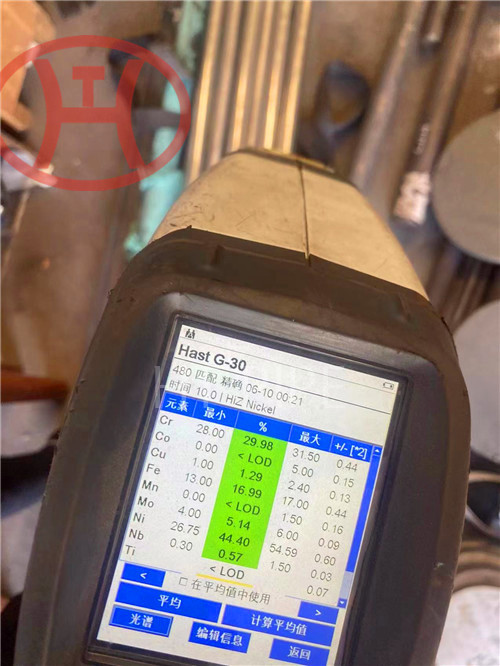

Chemical components & mechanical properties

| Standard | Grade | Chemical Components (%) | Mechanical Properties | ||||||

| ASTM A53 | C | Si | Mn | P | S | Tensile STrength(Mpa) | Yield STrength(Mpa) | ||

| A | ≤0.25 | – | ≤0.95 | ≤0.05 | ≤0.06 | ≥330 | ≥205 | ||

| B | ≤0.30 | – | ≤1.2 | ≤0.05 | ≤0.06 | ≥415 | ≥240 | ||

| ASTM A106 | A | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥415 | ≥240 | |

| B | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≥485 | ≥275 | ||