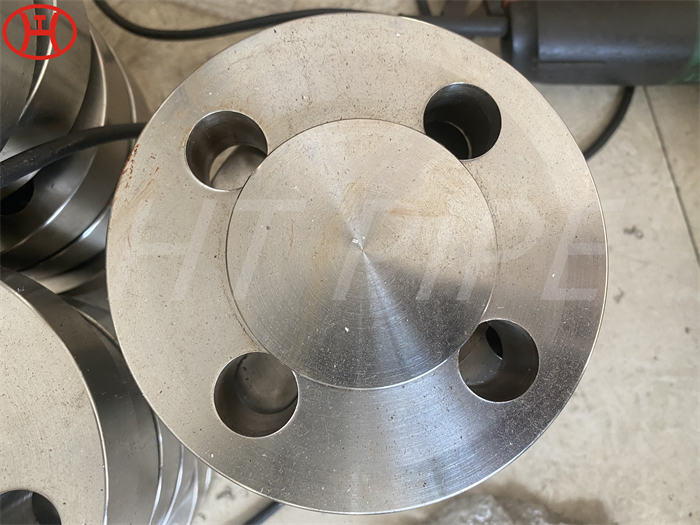

S31254 Stainless Steel Flanges PN 25 PN 40 PN 64 upto PN 160 Flanges

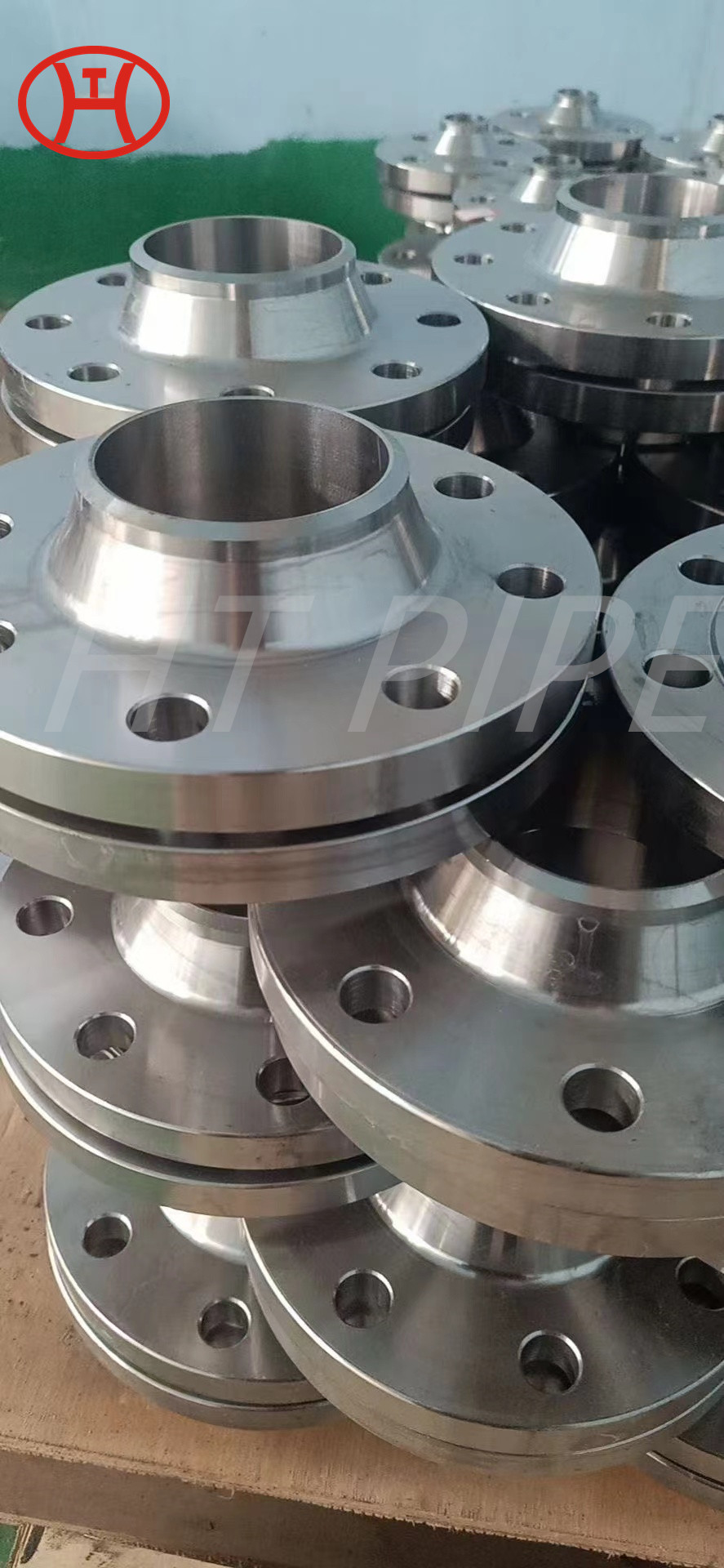

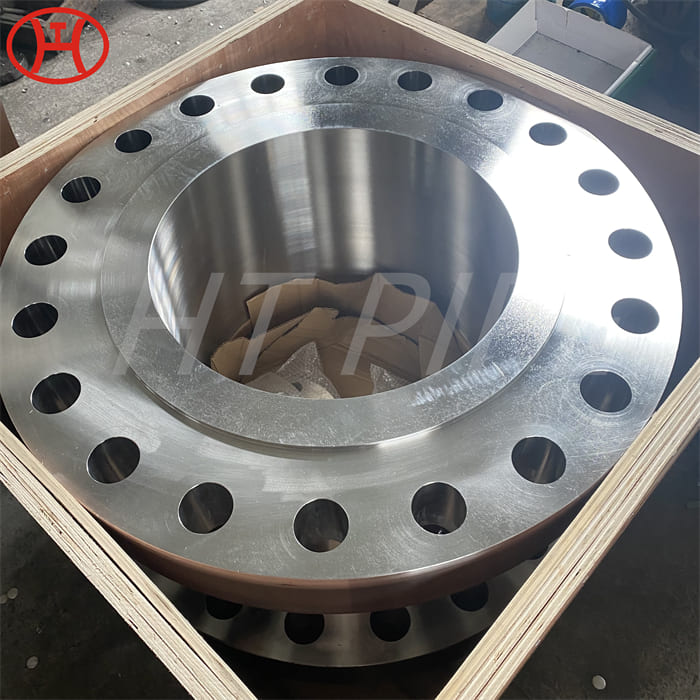

The different types of flanges such as the 254 SMO Slip on Flange have good corrosion resistance due to the composition. The flanges are also stronger than the ordinary stainless steel flanges with 650MPa minimum tensile strength, 300MPa minimum yield strength and 35% elongation rate.

Generally, lower austenitic stainless steel grades such as alloy 304, is not deemed ideal for use in these conditions. Which is why the Alloy 254 Blind Flange is used in Desalination plant equipment, Seawater handling systems, Flue gas desulphurisation units in power plants along with Chemical processing, Paper and pulp as well as Control and instrumentation tubes. This grade is readily weldable and fabricable. In the refining process, its structure has a tougher and stronger structure after performing the heat treatment process. The standard welding operations performed on flanges are TIG, MIG, submerged arc welding, resistance welding and more. The machinability of grade requires low speeds, feeds, cut depths, coolants, and lubricants. Referred to as a superalloy, the ASTM A182 SMO 254 Lap Joint Flange is designed to withstand elevated temperature settings, while conforming to not only its chemical, but also mechanical requirements set by the specification. Per the ASTM A182 specification, the mechanical properties that the UNS S31254 SMO Slip On Flange is to conform to includes requirements such as tensile strength, yield strength, elongation as well as Brinell hardness.