Home » Materials » Duplex steel » S32750 S32760 Super duplex stainless steel pipes with good general corrosion resistance

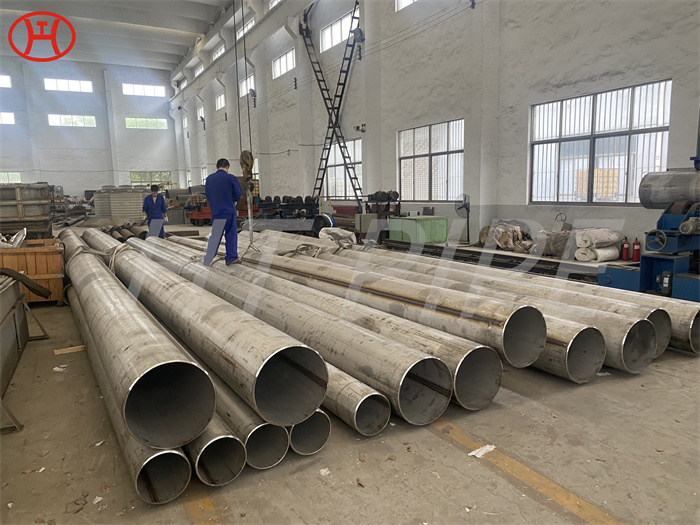

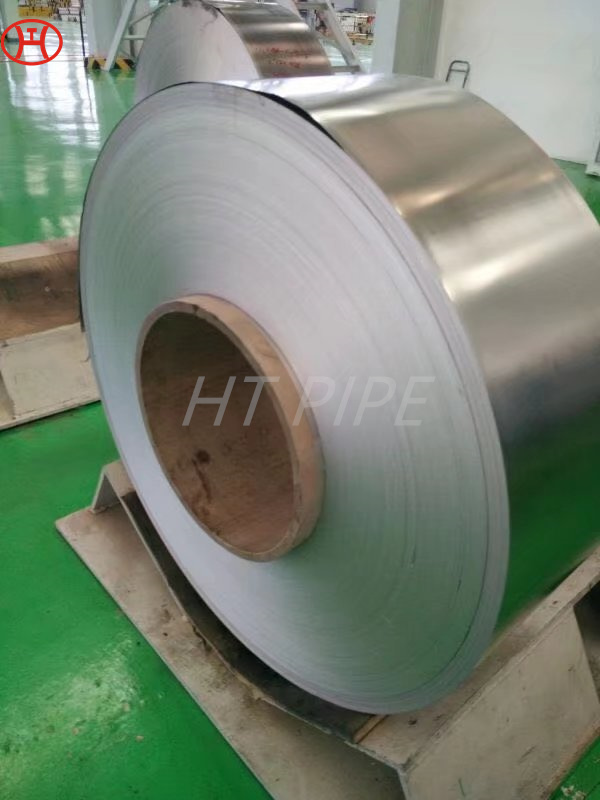

S32750 S32760 Super duplex stainless steel pipes with good general corrosion resistance

Super Duplex 2507 cannot be strengthened by heat treating. Annealing is performed at 1920¡ãF – 2060¡ãF (1049¡ãC – 1127¡ãC), followed by rapid cooling.

Contact US

Get Price

Share:

Content

Super Duplex 2507 Pipe enhances its properties. For instance, the ferritic part of the duplex microstructure in the alloy of the pipe is responsible for the Super Duplex 2507 Seamless Pipe exhibiting superior resistance to stress related corrosion cracking, particularly when exposed to warm chloride ion bearing circumstances. Super Duplex 2507 can be cold formed. However, it has a high work-hardening rate, so intermediate anneals may be required. Annealing is also recommended subsequent to hot forming or cold forming in order to achieve optimal stress corrosion resistance.

Inquiry

More Duplex steel