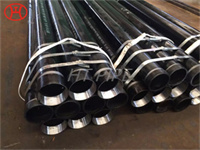

SA355 P91 Seamless Pipe Alloy steel seamless pipe

Alloy steel seamless pipes are widely used in medium and low pressure fluid pipelines, casings, boiler tubes, oil and gas industry, chemical industry, power generation industry, transformers, agriculture, bearings, general engineering, automobiles, hydraulics, railways, mining, construction, aviation Aerospace, medical, defense and electric motors. P91 alloy steel is mainly used in the power industry. For welded structures, the ASME Boiler and Pressure Vessel Code limits the carbon content to less than 0.35%. Alloy steels are ideal for applications that require higher strength, tougher or better wear resistance than standard carbon steel grades.

ASTM A335 GRADE P91 AS SEAMLESS PIPE, ALLOY STEEL SEAMLESS PIPES, AS SEAMLESS PIPE MANUFACTURER, P91 SEAMLESS ROUND PIPES, ALLOY STEEL ASTM A335 GRADE P91 SEAMLESS PIPE SUPPLIER.

P91 is a chrome moly alloy metal that contains excellent strength and temperature resistance. A355 P91 pipe is designed for enhanced creep strength, making A355 P91 pipe a creep strength enhanced ferritic (CSEF). This metal is made by normalizing at 1050 °C, air cooling to 200 °C, and then tempered through heating to 760 °C. This process is the main reason behind P91’s creep strength and durability. P91 stands for the metal’s composition of 9% chrome and 1% molybdenum plus vanadium. The chrome increases temperature strength and oxidation resistance. A335 grade p91 seamless pipe can be used as steel pipe for high-temperature superheater and reheater of subcritical and supercritical boilers with wall temperature ≤ 625 ℃, as well as high-temperature header and steam pipe with wall temperature ≤ 600 ℃, as well as nuclear electric heat exchanger and furnace pipe of petroleum cracking unit.

A335 P91 is a kind of high pressure and high temperature resistant steel. P91 bars, plates, pipes and pipe fittings. P91 is generally a355p91 in terms of title, which is equivalent to the national standard 10Cr9Mo1VNb. Alloy steel seamless pipe is a material of high-pressure and high-temperature steel pipe. The American standard is ASME sa-335/sa335m, with tensile strength ≥ 585 (MPA), yield strength ≥ 415 (MPA), and elongation ≥ 20 (%). P91 is characterized by thinner pipe wall thickness. Compared with other steel materials, the material consumption is reduced by more than 40%, and the material and installation cost are saved by more than 30%. Due to the reduced self weight of P91 seamless round pipe, the load of supports and hangers is also relatively reduced, which is convenient for support and installation.

High Pressure Temperature Steel AISI/SATM A355 P91 Seamless Pipes OD 20 Inch Sch-120

| Product Name | High Pressure Temperature Steel AISI/SATM A355 P91 Seamless Pipes OD 20 Inch Sch-120 |

| Material | ASTM A106,A53GRB,A53-A,A106-A,A192,A226,A315-B,A106-B,A178-C,A210-A-1,A210-C,A333-1.6,A334- 1.6,A333-7.9,A334-7.9,150M19,En46 and so on. |

| Color | black painted, galvanized |

| Standard | API 5L, API 5CT, DIN1629/2448, DIN17175, ASTM A53, ASTM A106B, ASTM A179, ASTM A210, ASTMA335, ASTMA519 and so on. |

| Size | 1/2″ ~48″, DN15~DN1200 OD21.3MM~1219.2MM |

| Wall Thickness | seamless pipe 1/2″ ~24″, DN15~DN600 OD21.3MM~609.6MM

Welded pipe 1/2″ ~48″, DN15~DN1200 OD21.3MM~1219.2MM |

| Surface Treatment | Transparent oil, rust-proof black oil or hot galvanized |

| Used | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, nuclear, etc |