SMO 254 Blind Flanges SMO 254 Weld Neck Flanges SMO 254 Forged Flanges Suppliers

With high ductility and impact strength, SMO 254 is a cheaper alternative to high nickel alloys and titanium alloys in some applications.

ASTM A182 254 SMO Flanges Supplier, Exporter, Manufacturer, SMO UNS S31254 Flanges, Alloy 254 SMO Long Weld Neck Flanges, Stainless Steel 254 SMO Slip on Flanges, 254 SMO Flanges, 254 SMO Pipe Flange Distributors, Stainless Steel 1.4539 Flanges, ASTM A182 254 SMO Socket Weld Flanges, 254 SMO Flanges Suppliers in China.

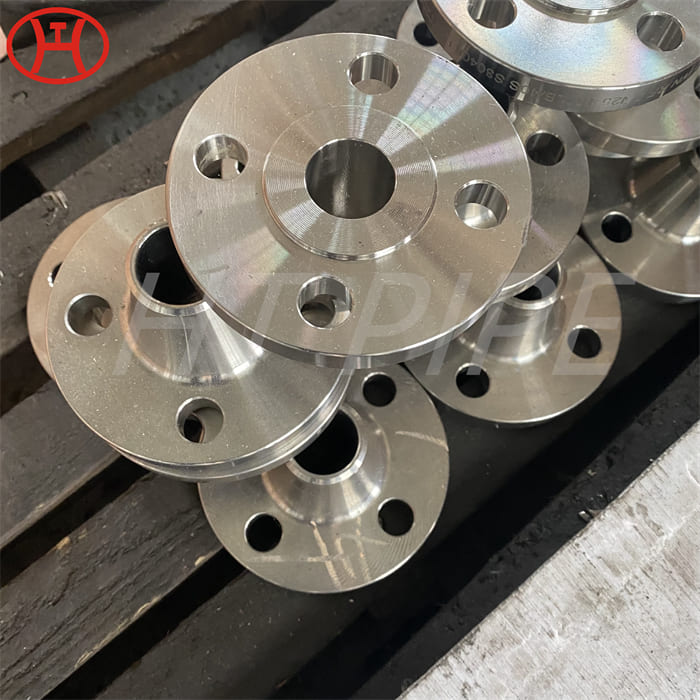

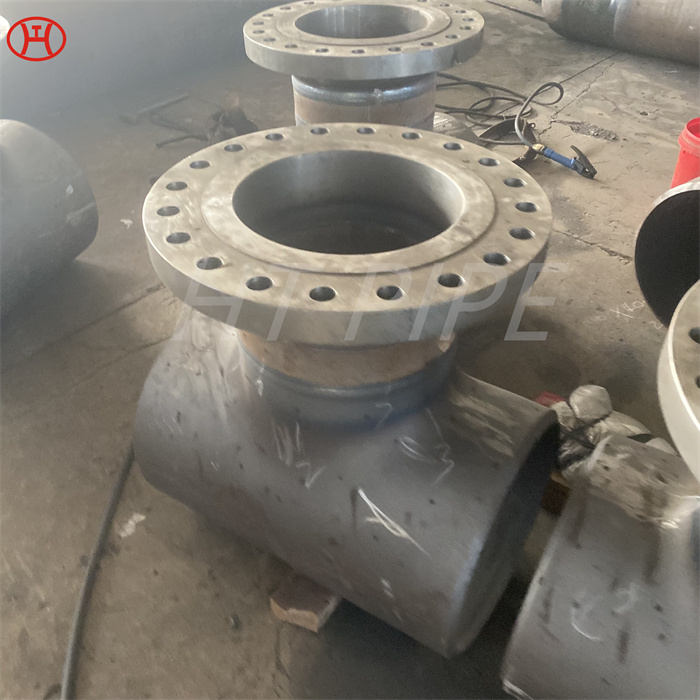

The UNS S31254 Weld Neck Flange is preferred in welding applications. These ASTM AASTM A182 254 SMO Flanges can hold the pipe in place during welding. SMO UNS S31254 Flange has up to 1390 degrees Celsius melting point so that it could be used in high temperature and high pressure applications such as power generation, heat exchangers, boiler and petrochemical industrial applications. SMO 254 Flanges are made up of an austenitic stainless steel with 19% chromium, 17% nickel and 6% nickel with copper and sulfur in the composition. This unique composition provides the material with high mechanical properties. HT PIPE is a leading supplier and manufacturer of Alloy 254 SMO Long Weld Neck Flanges. The Class 150 SMO UNS S31254 Flanges belong to one of the lower classes among a range of classes ranging from 150 to 2500 and PN6 through PN64. They are strong and corrosion resistant to most corrosive media, especially to chloride ion rich media. There are different types of flanges such as the 254 SMO Orifice Flange and others. All these flanges are strong with 650MPa minimum tensile strength and 300MPa minimum yield strength. The ANSI B16.5 ASTM A182 SMO 254 Blind Flange is one of the types used specifically to close a piping connection. The flanges belong to the specification ASTM A182. Stainless Steel 254 SMO Slip on Flanges could be specified according to different specifications such as the SMO Werkstoff No 1.4547 Slip-On Flanges as well.

The ASTM A182 F44 slip on flanges are used with seamless pipes in pipe lines. There are different standards such as the ASME B16.5, B16.47 Series A and B and others. The flanges can be SMO Grade 254 Threaded Flanges which are threaded to the pipes or the other types with bolts and nuts or connected only by welding. The size ranges from 1/2 inches to 48 inches in nominal bore size. The ASME SA182 SMO 254 Socket Weld Flanges are made with an added socket for extra grip and to hold onto the pipe. There are other structural types such as the 254 SMO RTJ Flange which is essentially a pair of rings connected to each pipe end. We also supply the SMO 254 Weld Neck Flange and any other custom designs as per customer requirements. Please contact us to know more about these flanges and their prices. HT PIPE is one of the most pronounced manufacturers, stockists and suppliers of SMO 254 Flanges due to the great service and products rendered by them. SMO 254 Flanges assures guaranteed resistance to granular corrosion in all the mineral acids. SMO 254 Pipe Flanges serves greatly to be employed in different chemical Industries all over the world and they are extremely useful to fight crevice corrosion and can be used in extreme environments of high pressure and temperatures. SMO 254 Flanges are available in different types like SMO 254 Slip on Flanges, SMO 254 Weld Neck Flanges, SMO 254 Blind Flanges and so on. The SMO 254 Slip on Flanges of HT PIPE is extremely durable and reliable and these attachments are connected to the pipe were fitted by welding at the top and bottom of the flanges and can be used in different industries. They are typically provided with a raised or flat face.

SMO 254 FLANGE STANDARD SPECIFICATIONS

| Product Name | SMO 254 Flanges |

| Size Range | 1/2″ (15 NB) to 48″ (1200NB) |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standards / Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605 |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Custom Design | As per your drawing | AS, BS, ANSI, DIN, JIS | Equal and Reducing Configurations |

| Material Test Certificates (MTC) | As per EN 10204 3.2 and EN 10204 3.1, Test Certificates certifying NACE MR0175, NACE MR0103 |

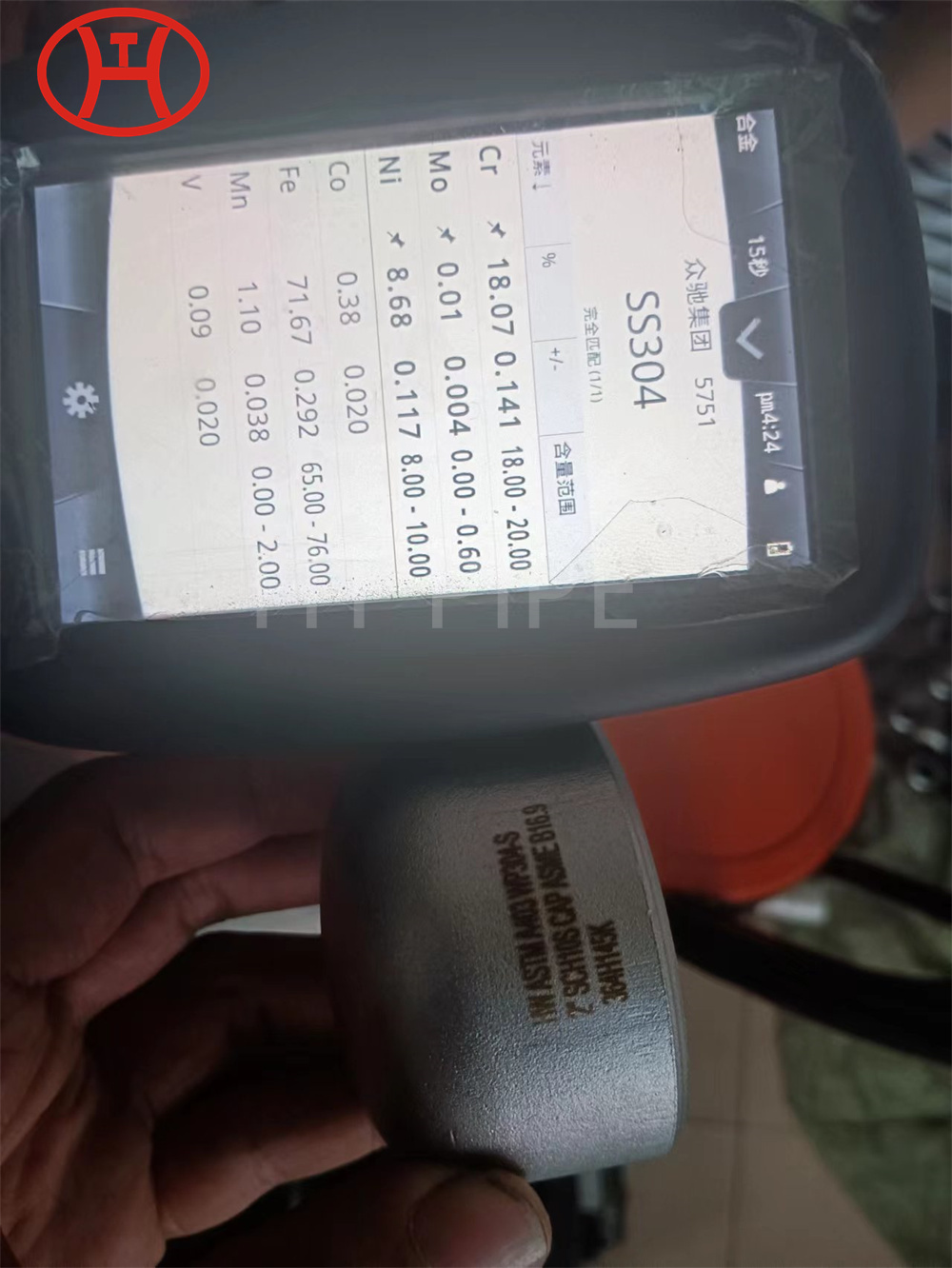

| Test Certificates | 100% Radiography Test Report, EN 10204/3.1B, Raw Materials Certificate, Third Party Inspection Report, etc |

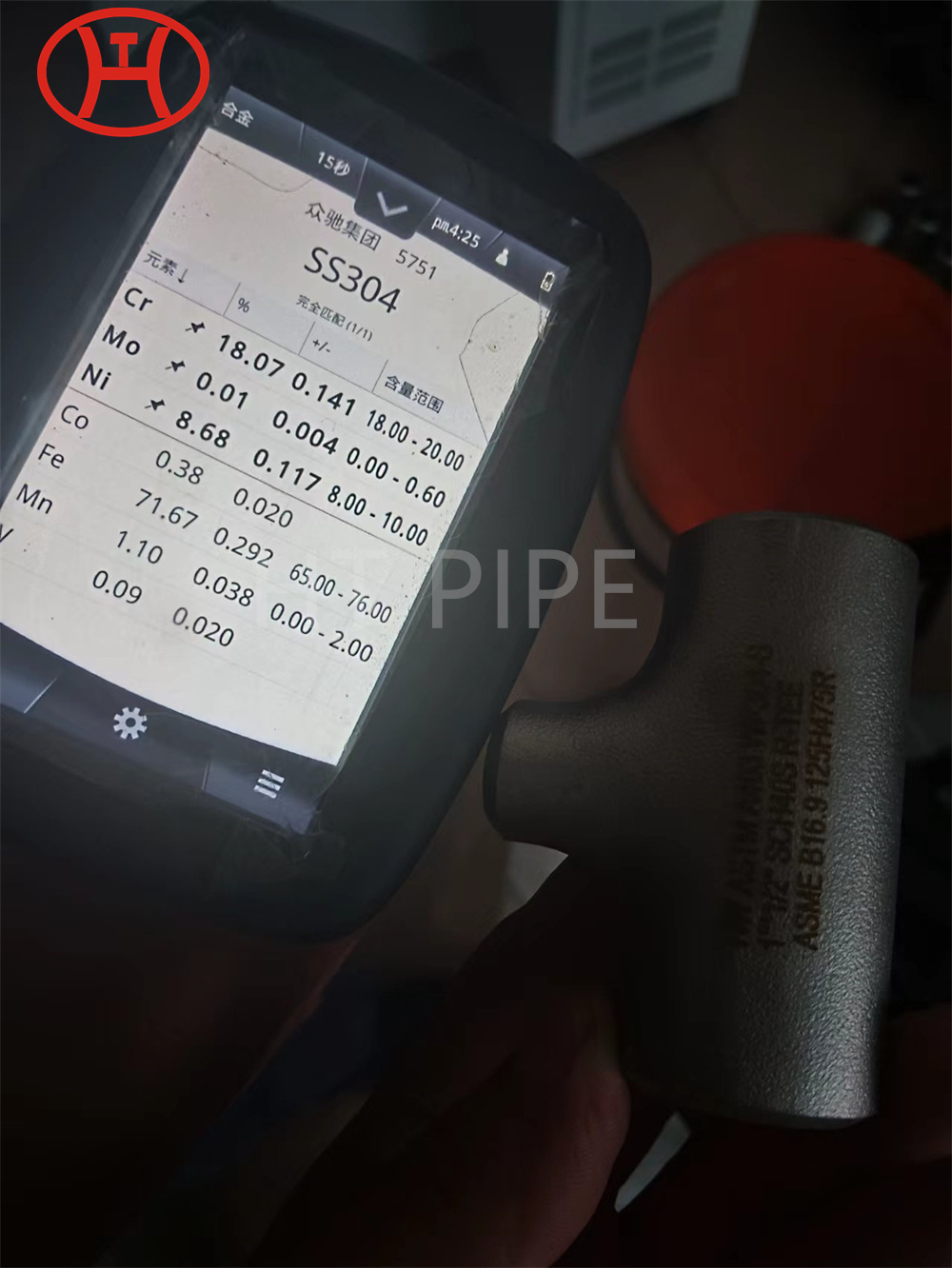

| Tests | Hydrostatic testing machine, Direct-reading Spectrograph, UI trasonic flaw detector, X-ray detector, Magnetic particle detector |

| Equipment / Machines | Press machine, Pushing Machine, Bending machine, Sand-blasting machine, electric bevelling machine, etc. |

| Coating | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |