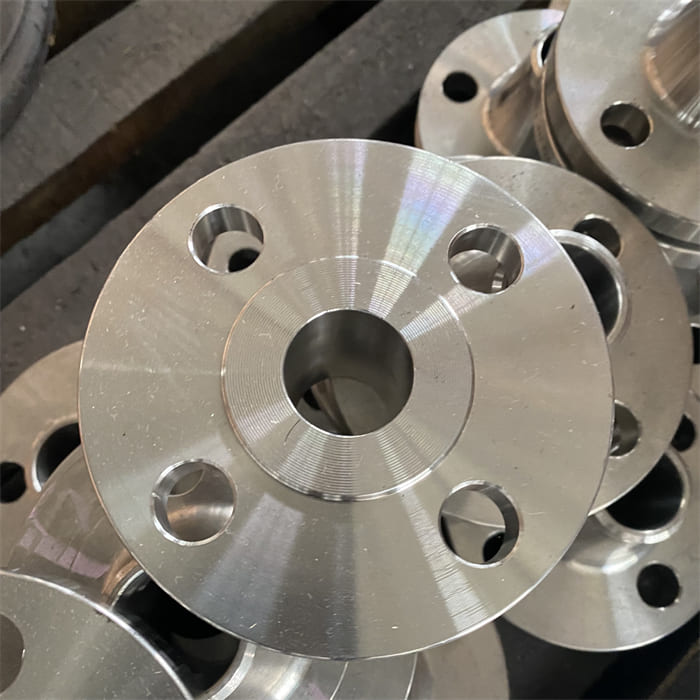

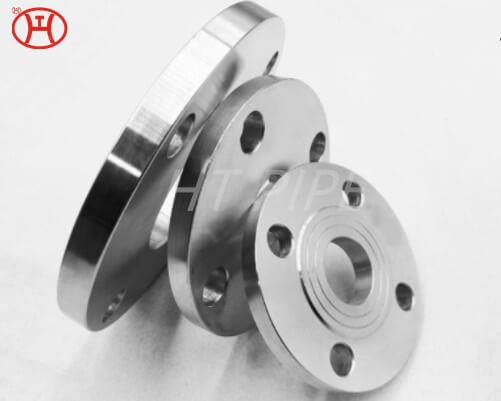

SMO 254 THREADED FLANGES UNS S31254 WN FLANGES SUPPLIER

Stainless steel Grade 254 SMO Flanges is quite tough to machine due to the extremely high work hardening rate and lack of sulfur content; however using sharp tools, overpowered machine tools, positive feeds, good amount of lubrication, and slow speeds tend to provide good machining results.

ASTM A182 WN FLANGES MANUFACTURER, SMO 254 INDUSTRIAL FLANGES STOCKHOLDER, ASME SA182 SMO 254 LAP JOINT FLANGE, SMO 254 SCREWED FLANGES STOCKIST, SMO GRADE 254 FORGED FLANGES MANUFACTURER.

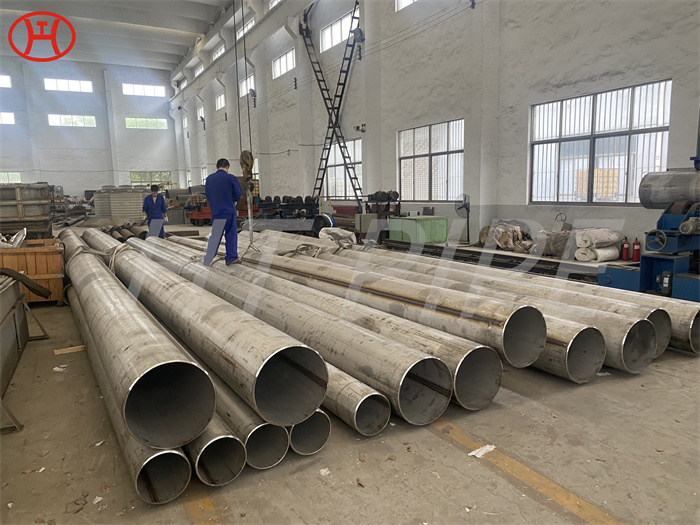

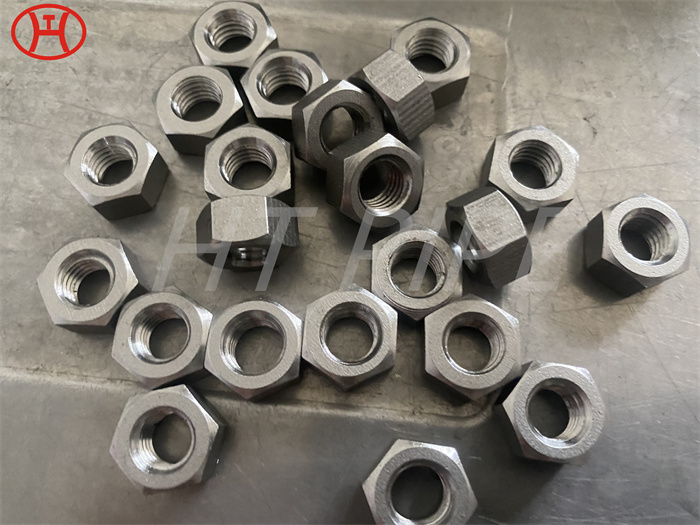

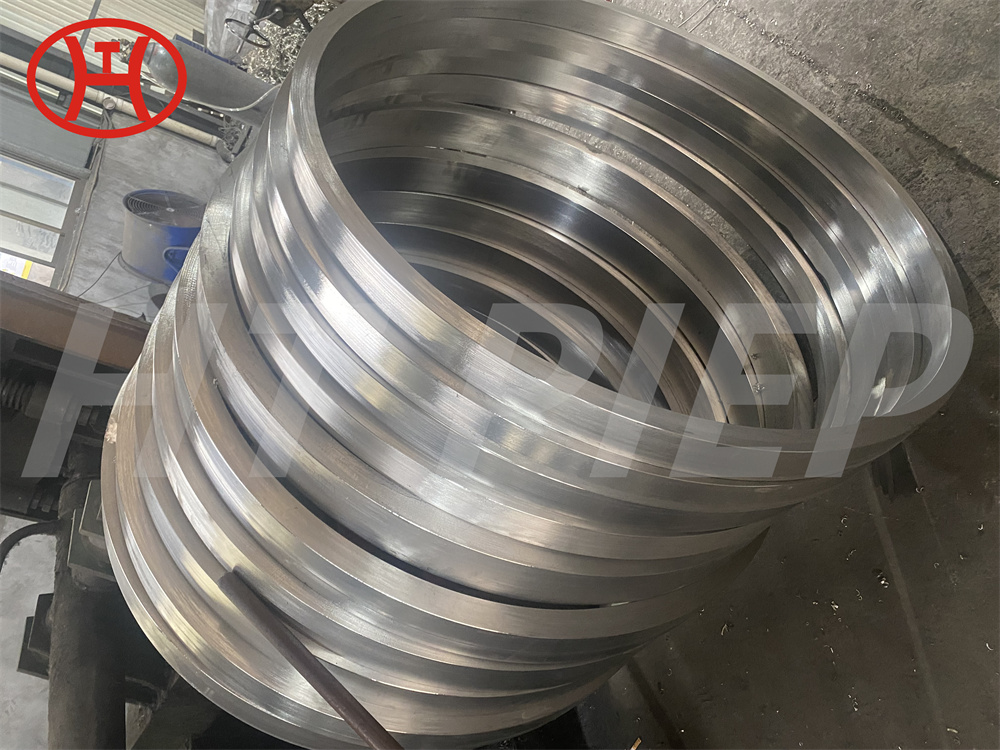

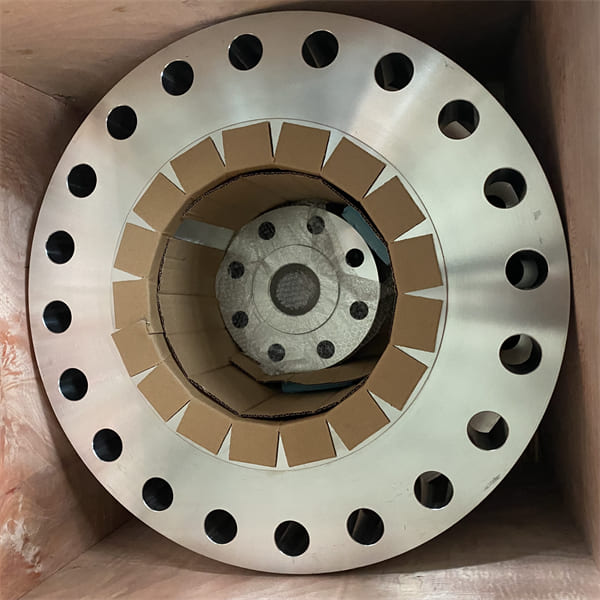

HT PIPE is a well-known manufacturer, supplier and exporter of these SMO 254 Flanges. We fabricate these SMO Flanges in various sizes, shapes, dimensions and length and as per the requirements of our esteem clients. We manufacture different types of these A182 F44 Flanges to provide a suitable solution across a diverse list of industries. We always focus on the need and demand of our clients and manufacture these SMO 1.4547 Flanges as per the requirement and request of our esteemed clients. We, HT PIPE are well known because of the best quality, easy availability, and affordable price. We always consider the needs and demand of our clients as well as industry and then make the best and suitable SMO 254 Flanges to serve them very efficiently. Our fabricated products are high in demand amongst our clients because of it’s features and long life services. Our SMO UNS S31254 Flanges are made up of the combination of Nickel, Chromium, Molybdenum metals to provide efficient performance, dimensional accuracy and durability.

Our SMO 254 Welding Neck Flange is being manufactured with national and international quality. Hence we utilize premium quality of raw material that is sourced from the reputed firm. Also, we hire advance and modern technology that is being used to fabricate accurate dimension product. Moreover to fulfill the requirement and needs of the patrons we offered customize shape and size product at quite an affordable price. These ASTM A182 UNS S31254 flanges consider great attachment and long-term working services to elevated temperature circumstances. Even more, ASME SA182 SMO 254 Slip On Flange comprises corrosion resistance, crevice, and stress corrosion resistance. SMO 254 Blind Flange also shows great ductility, durability, toughness, and strength. Thus these SMO 254 Forged Flanges are used in various industrial applications. The physical properties of Alloy 254 Flanges (UNS S31254) are essentially equivalent as described herein. Alloy 254 Pipe Flanges may offer a cost effective solution to Nickel and Titanium alloys in these environments. A182 F44 Flanges is designed with a combination of impact toughness resistance to chloride stress corrosion cracking, and pitting and crevice corrosion with strength that is twice that of the stainless steel 300 series. Coupled with Copper and Nickel this gives 254 SMO Pipe Flanges an excellent resistance to crevice and pitting corrosion, particularly in atmospheres comprising halide ions, such as chloride, fluoride and bromide solutions.