sockolet and weldolet

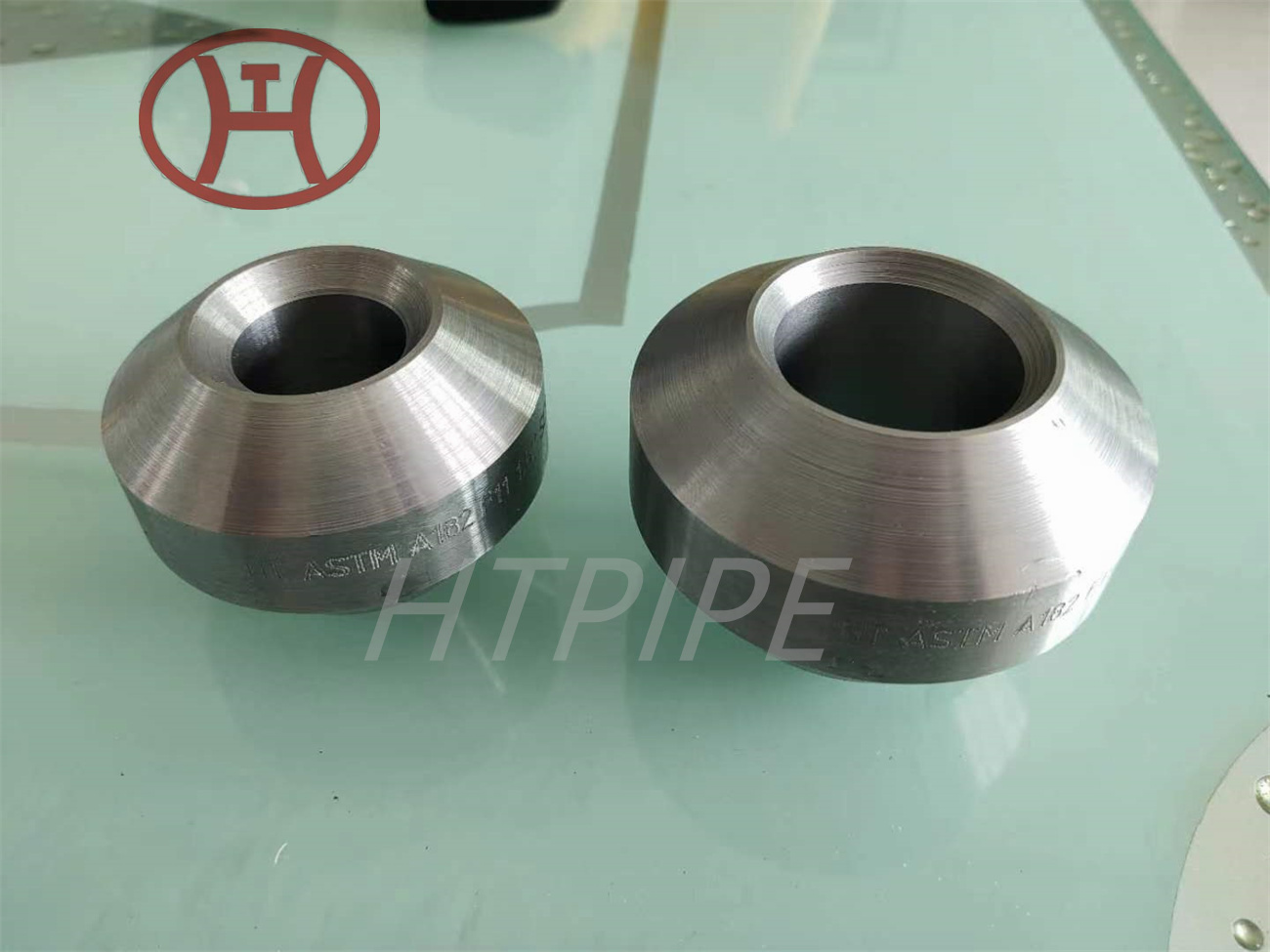

The use of branch fittings instead of conventional fittings (buttweld tee, reinforcing pads and saddles) has the following advantages (example Weldolet):

Just 2 welds are needed, instead of 3 (less work and weld inspections)

Accelerated installation time

Less space is required, making the piping system design more flexible

The flow is fully unrestricted, due to the funnel design

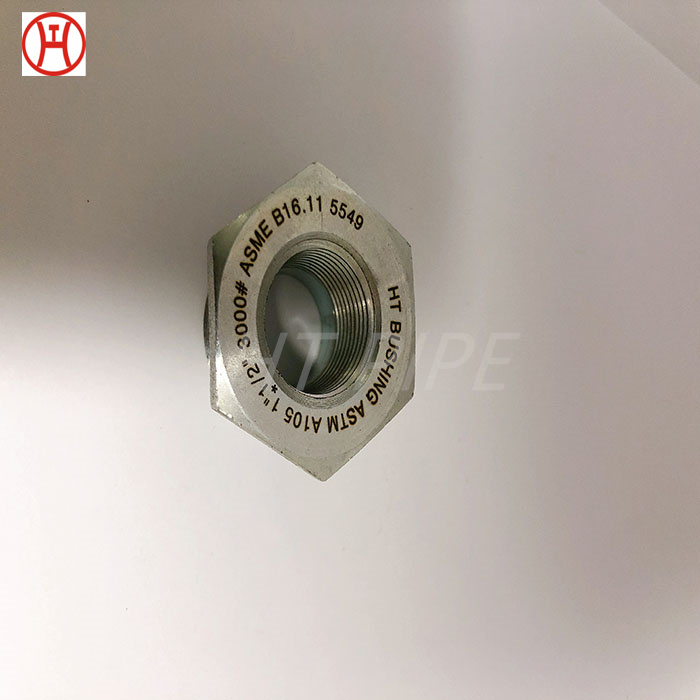

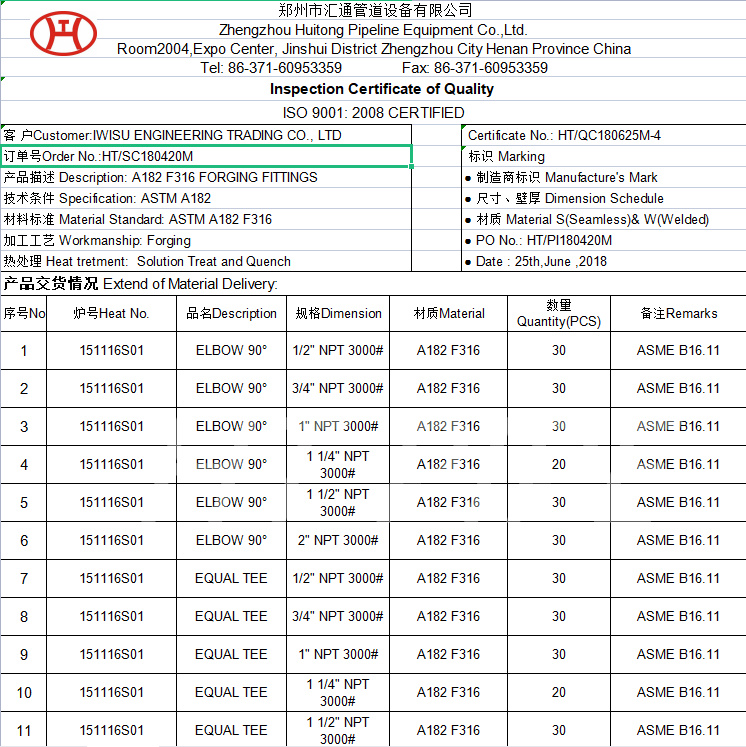

Reinforced branch connections are manufactured in a wide range of sizes (to accommodate most size on size or reducing connections), types/designs, connection types (buttweld, socket weld, threaded), and in a wide range of forged steel materials:

carbon steel (ASTM A105 for high-temperature, A350 LF2/LF3 for low-temperature)

alloy steel (ASTM A182 Grades F5, F9, F11, F22)

stainless steel (ASTM A182 F304, F316, and other SS grades)

nickel alloys (Inconel, Monel, Incoloy, etc).