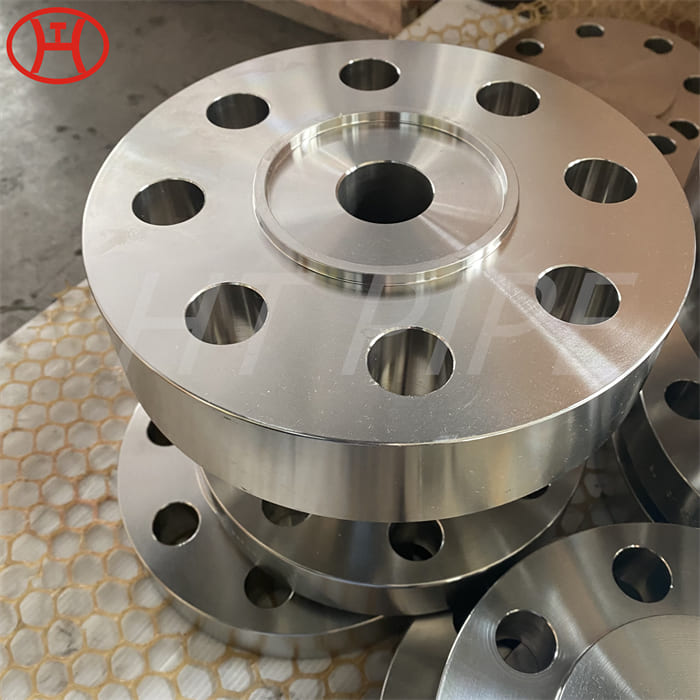

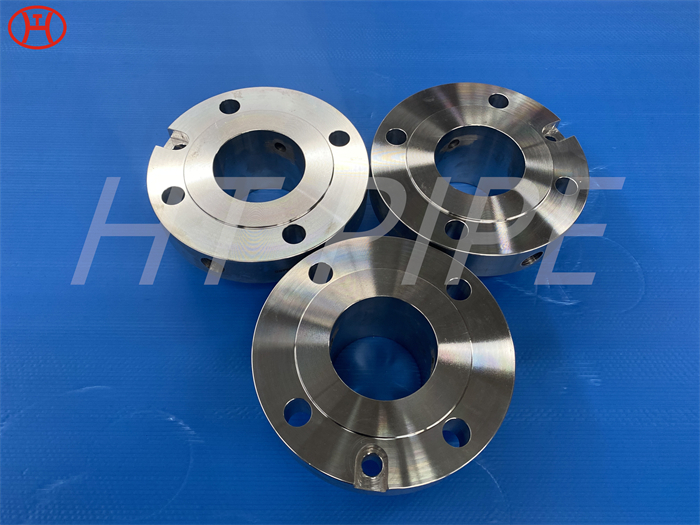

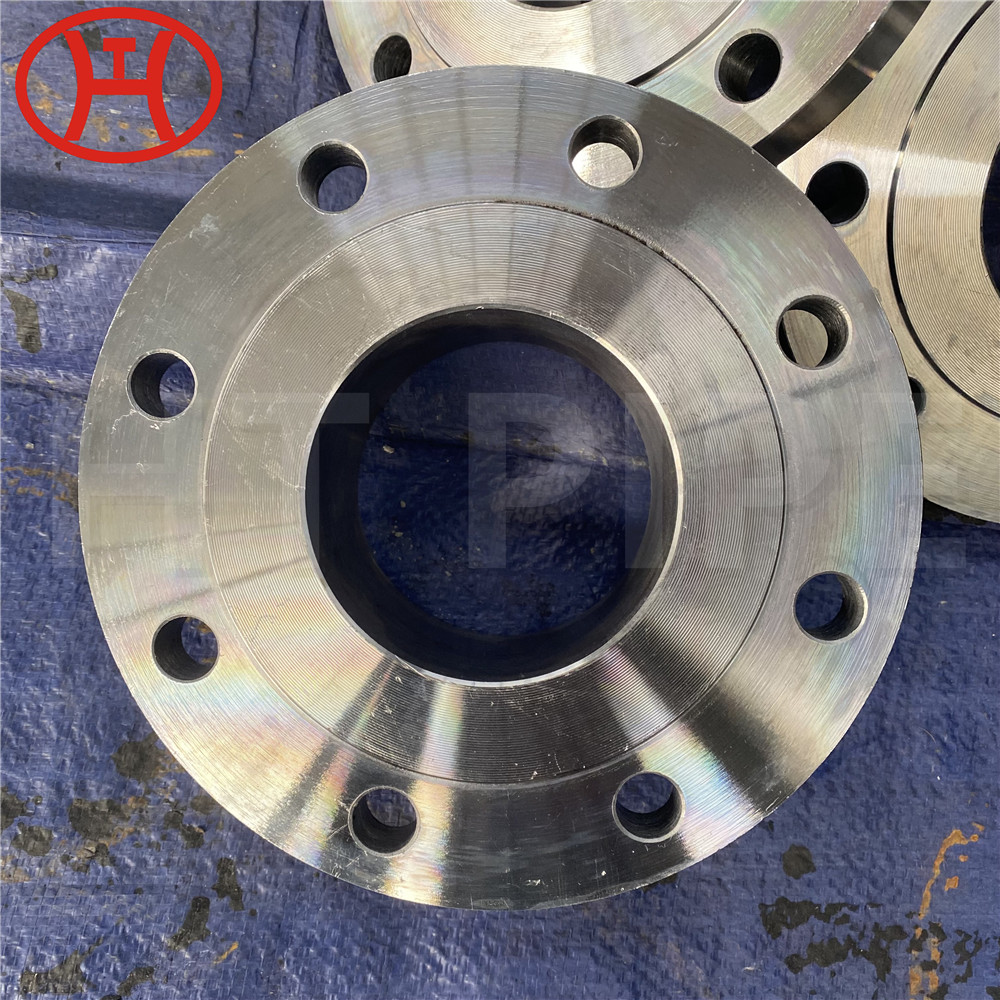

Home » Steel Pipe Fittings » Forged Pipe Fittings » Solution heat treatment304 Stainless Steel Socket Threaded Fittings NPT coupling

Solution heat treatment304 Stainless Steel Socket Threaded Fittings NPT coupling

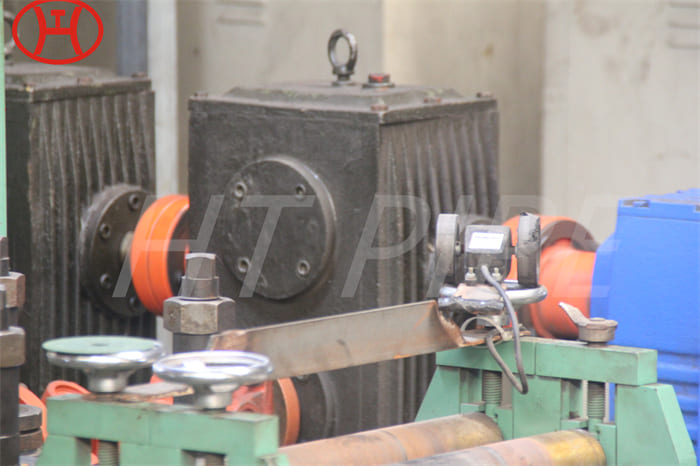

Solution treatment is the most common heat treatment method after stainless steel casting process. The carbide phase is completely or substantially dissolved after the austenitic stainless steel is heated to about 1100 ¡ãC .

Contact US

Get Price

Share:

Content

ith the method of solution treatment, stainless steel castings are softened. Generally, stainless steel castings are heated to around 950-1150 ¡ãC and kept for a period of time for the purpose of making carbides and various alloy elements to be fully and uniformly dissolved in austenite, and then it is quickly quenched and cooled. The carbon and other alloy elements are too late to precipitate, and a pure austenite structure is obtained, which is named solid solution treatment.

Inquiry

More Stainless steel