SS 304H blind flanges SS 304H flat face flanges stockholders

For maximum corrosion resistance, forgings should be annealed at 1900°F minimum and water quenched or rapidly cooled by other means after hot working operations.

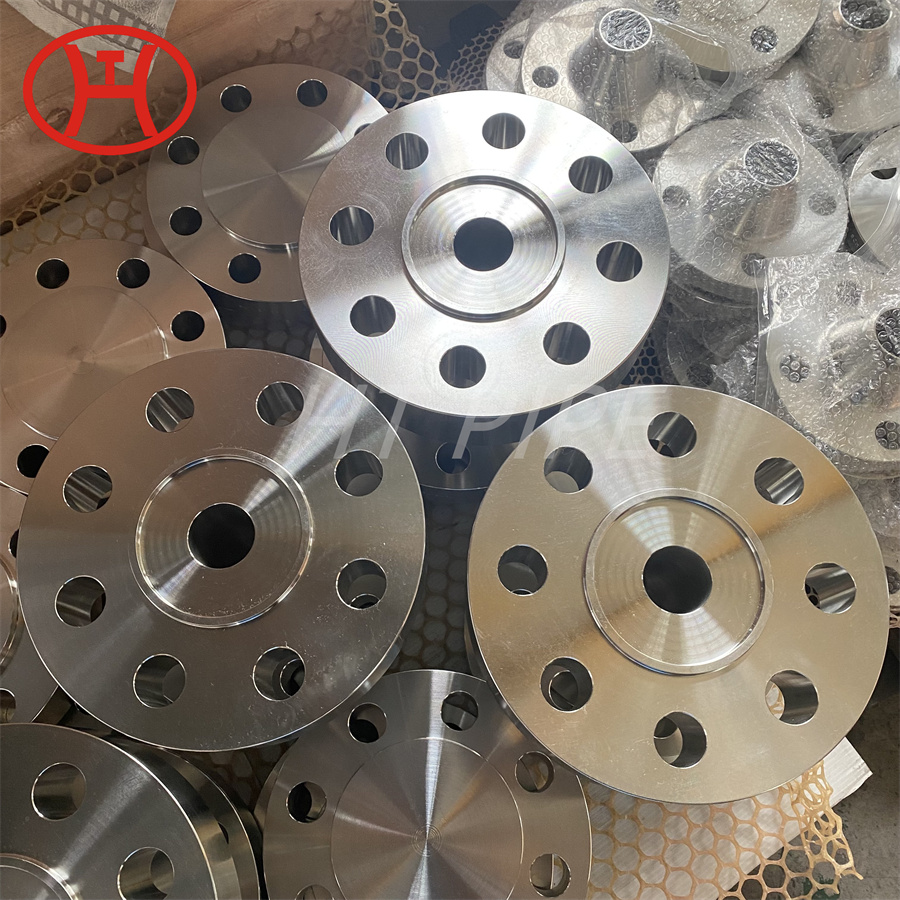

SA182 F304H Blind / Weld Neck And ASTM A182 F304H Slip On Flange Manufacturer In China

ASTM A182 F304H blind flange is a component that is designed without a hub or a boring center. These flanges are utilized to seal ends of hydraulic fluids or gases. SS 3SS 304H Weld Neck Flanges can also be employed to put a stop in the pipeline to carry out repairs or install new components across the piping system. The high-strength flanges can withstand different pressures and temperatures while effectively ensuring that fluids and gases are tightly sealed. These SS F30SS F304H Flanges can be either welded or bolted. If they are bolted, they allow for room for maintenance and inspection within the pipeline. UNS S30409 Pipe Flanges come with either a raised or flat face type setting. HT PIPE is one of the specialized production house & dealer of SS 304H Flanges, which is a steel alloy with a minimum of 10.5 % chromium content by mass. Our Stainless Steel 304H Slip On Flanges is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications. These Stainless Steel 304H Threaded Flanges does not readily corrode, rust or stain with water as ordinary steel does.

Stainless Steel 304H Flange of high quality and strength is supplied by HT PIPE. We stock ASTM A182 F304H Flange in many different sizes. Siddhagiri Metals and Tubes looks at all aspects of our business to find ways we can improve. That includes processes, products and our relationship with the clients. A flange joint is a connection of pipes, where the connecting pieces have flanges by which the parts are bolted together. The principle of Stainless Steel 304H Flange is to apply a mechanical force by using bolts to preload the gasket until contact stress between flanges and gasket is sufficient to maintain a seal. Connection to the pipe is by welding or threading. To allow easy functionality and inter-changeability, these ASTM A182 UNS S30409 Flanges are designed to have standardised dimensions which include ANSI, ASME, DIN, EN, BS, JIS. Flanges have major applications in Oil, Gas, Petrochemical, Ship-Building, Marine, Food, Dairy, Railways and other associated industries were piping systems are required.

Physical properties of 304H grade stainless steel in the annealed condition

| Grade | Density(kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C (J/kg.K) | Electrical Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 304/L/H | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |