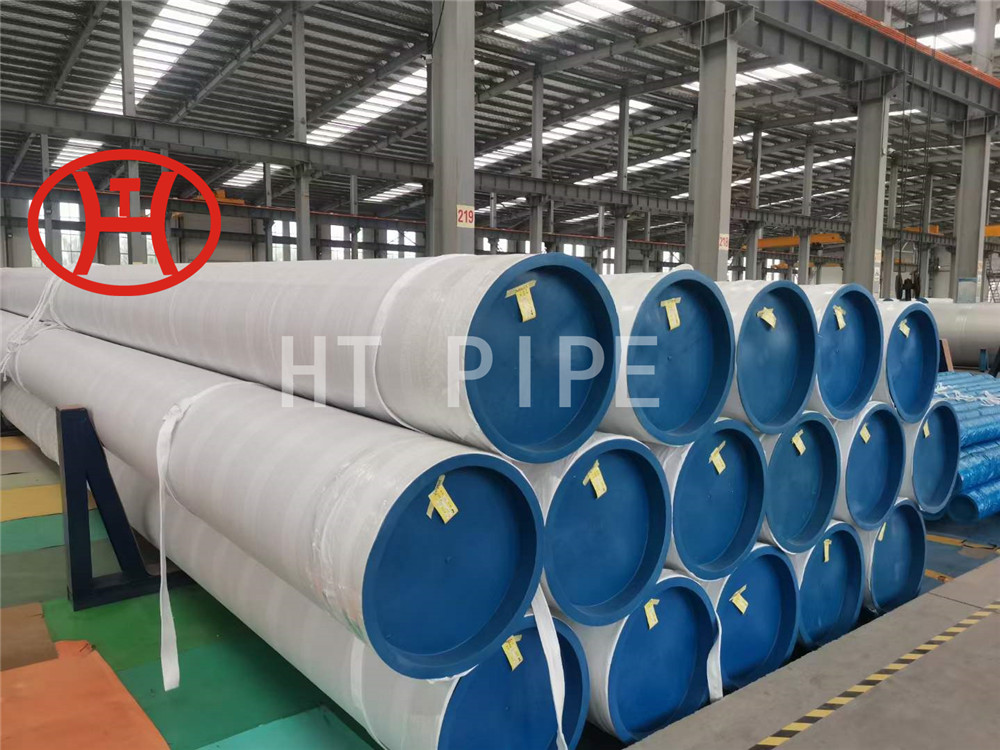

SS 316 Thin wall stainless steel pipe tube

All in all, if you need superior corrosion resistance and your application contains water, then 316 steel is worth it. If not, 304 steel will suit your needs well.

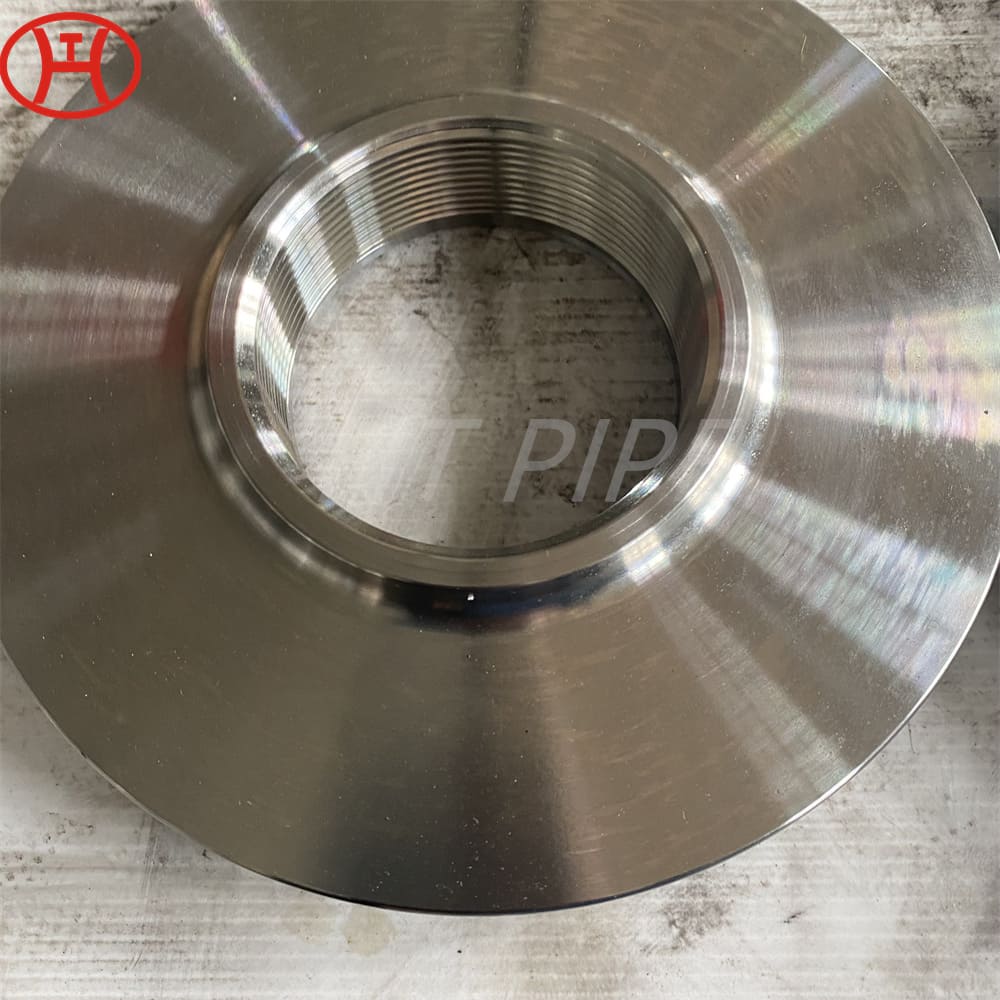

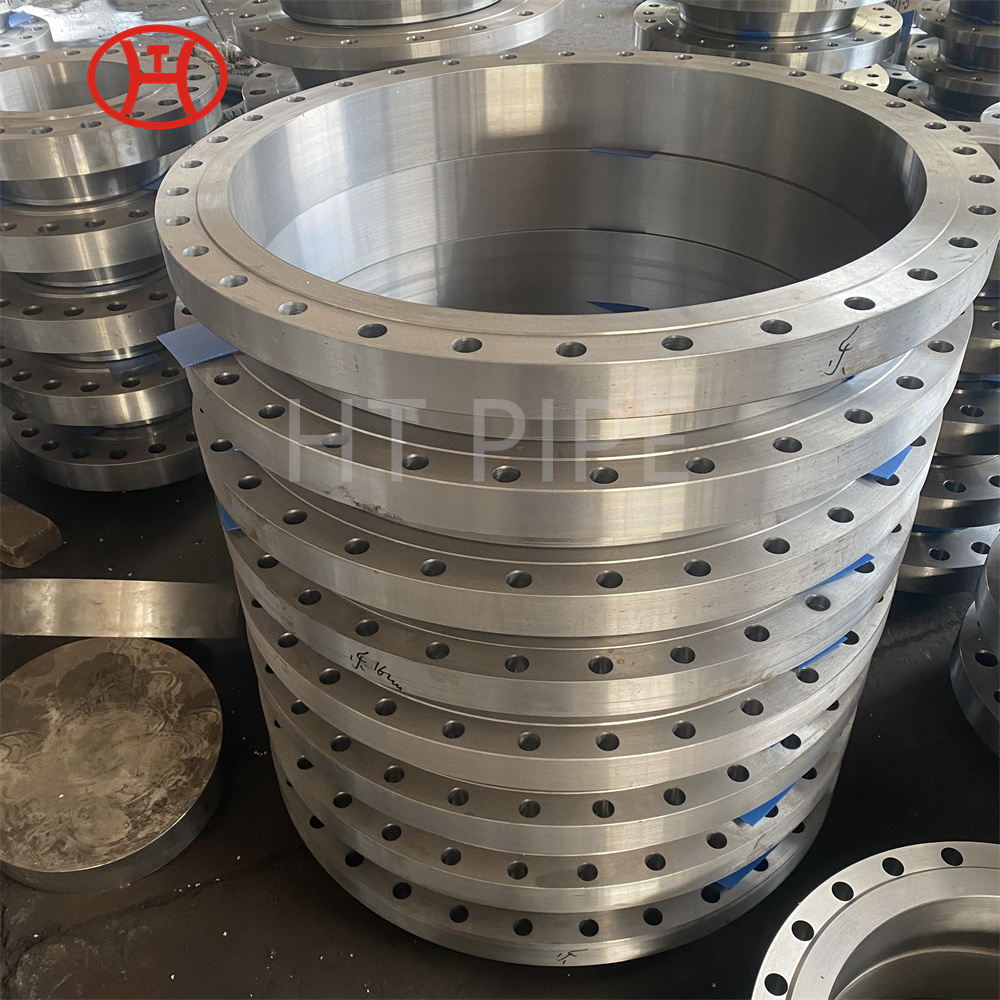

316 STAINLESS STEEL PIPES, 316 STAINLESS STEEL SEAMLESS PIPE & TUBES, 316 STAINLESS STEEL TUBES, 316 STAINLESS STEEL WELDED PIPES AND TUBES, 316 STAINLESS STEEL TUBING, UNS S31600 PIPES AND TUBES.

Stainless steel 316 pipe is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels. The molybdenum gives stainless steel 316 pipe better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. It has excellent forming and welding characteristics. It is readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields. Stainless steel 316 pipe also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

Grade 316L, the low carbon version of 316 and is immune from sensitisation (grain boundary carbide precipitation). Thus it is extensively used in heavy gauge welded components (over about 6mm). Grade 316H, with its higher carbon content has application at elevated temperatures, as does stabilised grade 316Ti.

The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures.

Stainless steel 316 pipe is the preferred steel for use in marine environments because of its greater resistance to pitting corrosion than other grades of steel. The fact that stainless steel 316 pipe is negligibly responsive to magnetic fields means that it can be used in applications where a non-magnetic metal is required. In addition to molybdenum, 316 also contains a number of other elements in varying concentrations. Like other grades of stainless steel, marine grade stainless steel is a relatively poor conductor of both heat and of electricity when compared to metals and other conductive materials.

While 316 is not completely rust-proof, the alloy is more corrosion-resistant than other common stainless steels. Surgical steel is made from subtypes of 316 stainless steel.

SS 316 Seamless Pipes Chemical Composition:

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | min. | – | – | – | – | – | 16.0 | 2.00 | 10.0 | – |

| max. | 0.08 | 2.00 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | |

Mechanical properties Of 316 Stainless Steel Pipes and Tubes:

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40% | 95 | 217 |