SS 316l Butt weld Fittings Stainless steel elbow

316L elbow is particularly useful in severe corrosive conditions as it is non-magnetic and austenitic stainless steel. It offers brilliant resistance to oxidation and pitting. Pipe Fittings SS 316 /316L is ideal for many industrial processes that require a high resistance in harsh environments. These tubular fittings can withstand many acidic solvents, chemicals as well as chloride pitting. We are widely known for delivering products according to our esteemed customers’ urgent requirements.

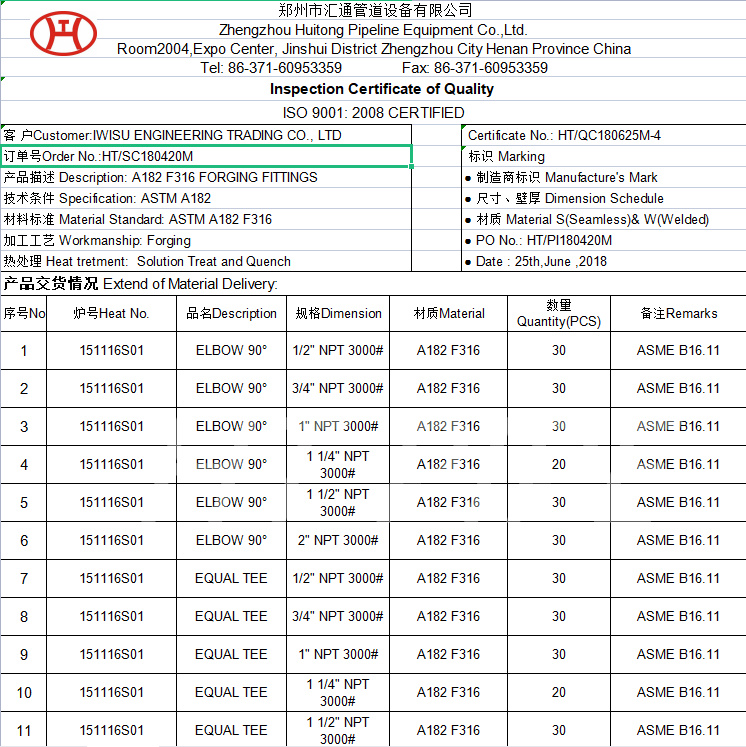

SS 316L Butt Weld Fittings (DIN 1.4404) is widely used in the chemical and oil & gas industries for its reasonable corrosion resistance and easiness of manufacture. The low content of carbon of Stainless Steel 316L Butt Weld Fittings (UNS S31603) decreases the option of in vivo erosion for medical implant usage. These stainless steel tube elbows have good corrosion resistance properties in harsh conditions. The low carbon in the SS 316L Pipe Fittings prevents post-weld graining and allows them to be easily welded following standard welding procedures. The Stainless Steel 316L Pipe Fittings / ASTM A403 WP316L possess a density of 8000 kg/m3 with an elastic modulus of 193GPa. 316L covers the standard for wrought austenitic stainless steel fittings for pressure piping applications. The material for fittings shall consist of forgings, bars, plates, or seamless or welded tubular products. Forging or shaping operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining, or by a combination of two or more of these operations. All fittings shall undergo heat-treatment.