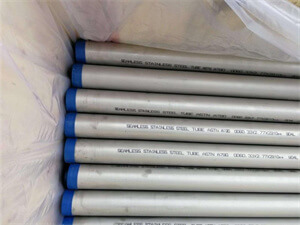

SS 904L ERW Pipes ASTM A213 Stainless Steel 904L Tubes Supplier

It also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum.

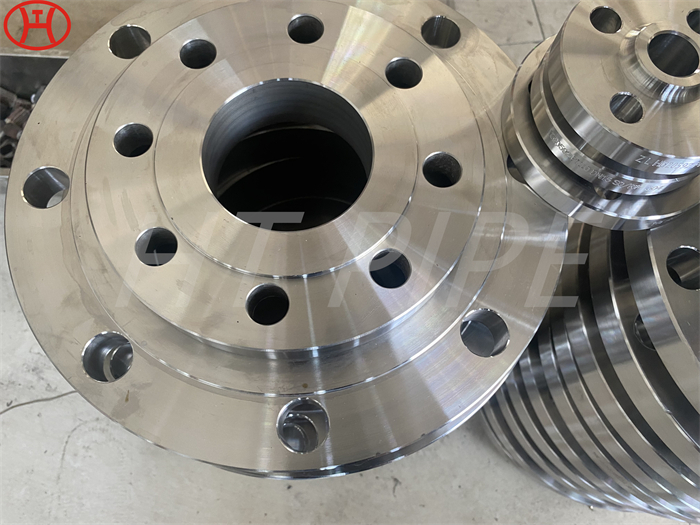

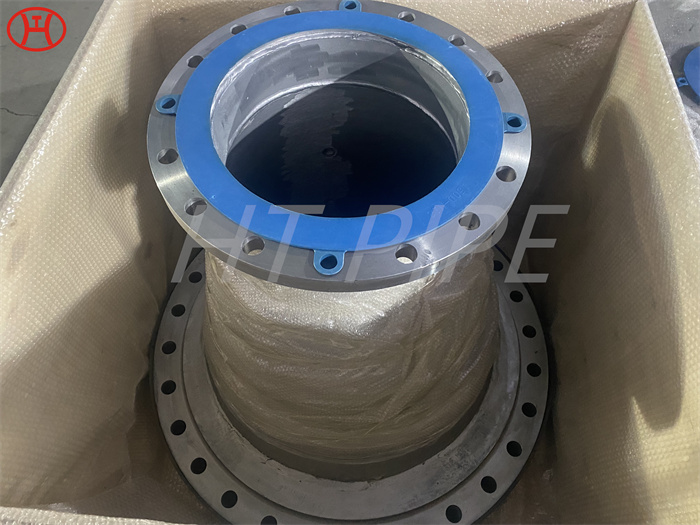

UNS N08904 pipes wall thickness, 904l rectangular steel pipes, 904L ss round pipe, Schedule 40 stainless steel 904l pipes dimensions, Seamless stainless steel 904l pipes stock, ASTM A677 din 1.4539 pipes manufactures in China, 904L stainless steel pipes schedule, SS 904l pipe, Stainless steel 904l pipes distributors, Polished stainless steel 904l pipe

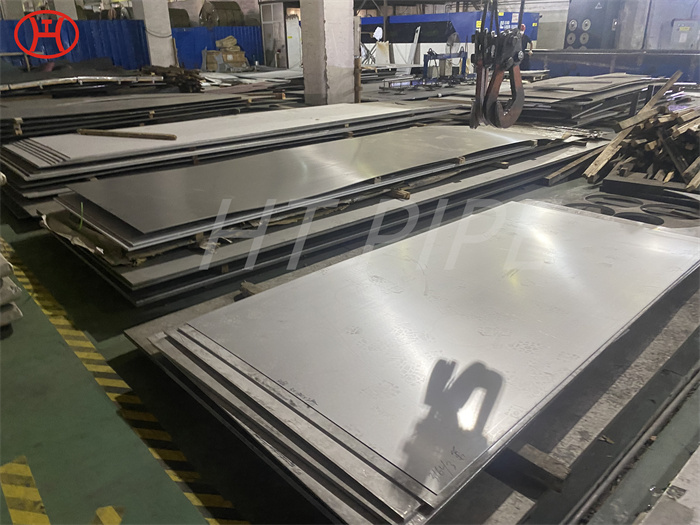

SS 904L Seamless Pipes have excellent resistance to warm seawater and chloride attack. The high resistance of SS 904L Welded Pipe against stress corrosion cracking is due to the presence of high amounts of nickel in its composition. Moreover, the addition of copper to these grades develops resistance to sulphuric acid and other reducing agents in both aggressive and mild conditions. Structurally, ASTM B677 TP 904L Stainless Steel Pipe is fully austenitic and is less sensitive to precipitation ferrite and sigma phases than conventional austenitic grades with high molybdenum content.

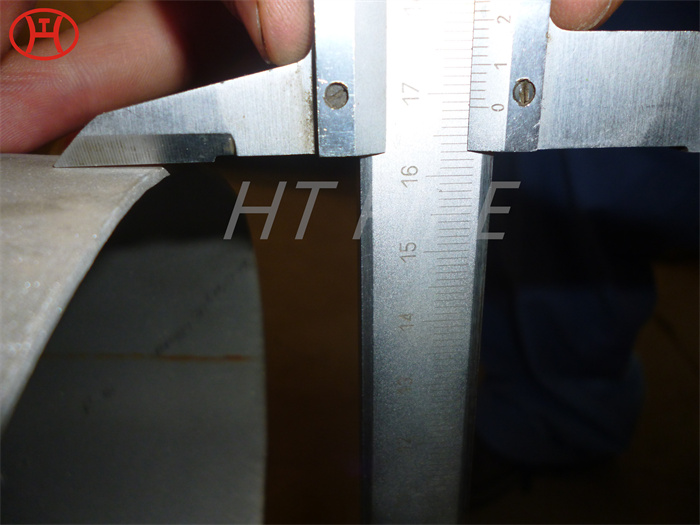

ASME SA 312 904L Stainless Steel Pipe has a good resistance to general corrosion, particularly in sulfuric and phosphoric conditions. The corrosion resistance of N08904 is intermediate between super austenitic grades, with 6% molybdenum content, and standard 316L austenitic grades. 904L Stainless Steel Pipe is less resistant to nitric acid than grades 304L and 310L, which are free of molybdenum. This 904L thin wall stainless steel tube needs to be solution treated following cold working, to achieve maximum stress corrosion cracking resistance under critical environments.

Super austenitic stainless steel 904L (00Cr20Ni25Mo4.5Cu; UNS: N08904; EN: 1.4539) is a high-alloy austenitic stainless steel with low carbon content. It has good corrosion resistance in dilute sulfuric acid and is specially designed for corrosion conditions. Designed for harsh environments. It has a high chromium content and sufficient nickel content. The addition of copper makes it highly resistant to acid, especially to chloride crevice corrosion and stress corrosion cracking. It is not easy to appear corrosion spots and cracks, and is resistant to spots. Corrosion ability is slightly better than other steel grades, has good workability and weldability, and can be used in pressure vessels.

PREN of Various Grades of Stainless Steels

| Grade | Type | Cr | Mo | N | PREN |

| Ferritics | |||||

| 1.4003 | – | 10.5-12.5 | NS | 0.030 max | 10.5-12.5 |

| 1.4016 | 430 | 16.0-18.0 | NS | NS | 16.0-18.0 |

| 1.4113 | 434 | 16.0-18.0 | 0.9-1.4 | NS | 19.0-22.6 |

| 1.4509 | 441 | 17.5-18.5 | NS | NS | 17.5-18.5 |

| 1.4521 | 444 | 17.0-20.0 | 1.8-2.5 | 0.030max | 23.0-28.7 |

| Austenitics | |||||

| 1.4301 | 304 | 17.5-19.5 | NS | 0.11max | 17.5-20.8 |

| 1.4311 | 304LN | 17.5-19.5 | NS | 0.12-0.22 | 19.4-23.0 |

| 1.4401/4 | 316/316L | 16.5-18.5 | 2.0-2.5 | 0.11max | 23.1-28.5 |

| 1.4435 | 316L (2.5% min Mo) | 17.0-19.0 | 2.5-3.0 | 0.11max | 25.3-30.7 |

| 1.4406 | 316LN | 16.5-18.5 | 2.0-2.5 | 0.12-0.22 | 25.0-30.3 |

| 1.4539 | 904L | 19.0-21.0 | 4.0-5.0 | 0.15max | 32.2-39.9 |

| 1.4563 | Sanicro 28 | 24.0-26.0 | 3.0-4.0 | 0.11max | 35.9-43.0 |

| 1.4547 | 254SMO | 19.5-20.5 | 6.0-7.0 | 0.18-0.25 | 42.2-47.6 |

| Duplex | |||||

| 1.4162 | Lean Duplex | 21.0-22.0 | 0.1-0.8 | 0.20-0.25 | 24.5-28.6 |

| 1.4362 | 2304 | 22.0-24.0 | 0.1-0.6 | 0.05-0.20 | 23.1-29.2 |

| 1.4462 | 2205 | 21.0-23.0 | 2.5-3.5 | 0.10-0.22 | 30.8-38.1 |

| 1.44102 | 2507 | 24.0-26.0 | 3.0-4.0 | 0.24-0.35 | > 40.2 |