SS 904L Tubing Manufacturer 904L Stainless Steel Pipes Supplier

The high chromium content promotes and maintains a passive film which protects the material in many corrosive environments.

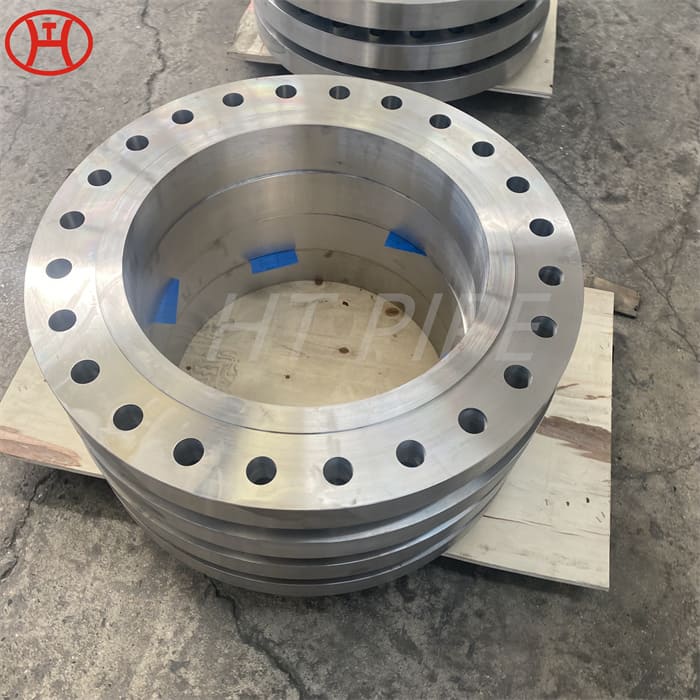

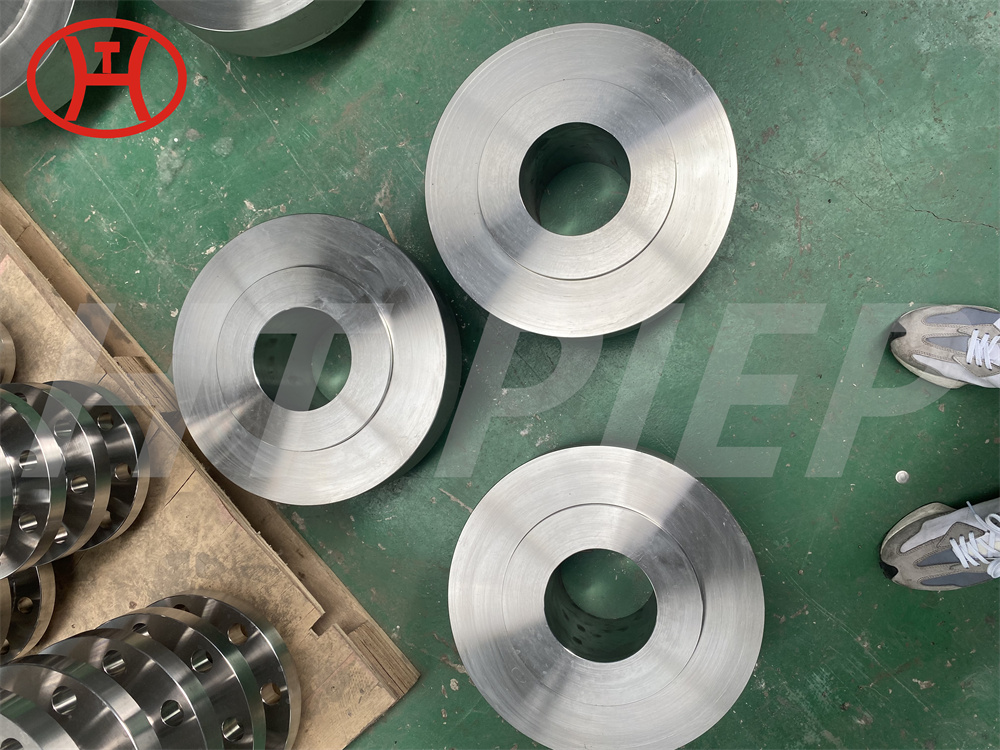

Stainless Steel 904L Pipes Manufacturers & Suppliers, Seamless & Welded 904L Stainless Steel Pipes – Top Quality SS 904L Seamless Pipes at Best Prices,UNS N08904/1.4539 & 904L Seamless Pipes

904L (N08904, 1.4539) super austenitic stainless steel contains 14.0-18.0% chromium, 24.0-26.0% nickel, and 4.5% molybdenum. 904L stainless steel pipe has good activation-passivation transformation ability, excellent corrosion resistance, good corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid, and phosphoric acid, and has good corrosion resistance in neutral chloride-containing media. Very good resistance to pitting corrosion, as well as good resistance to crevice corrosion and stress corrosion.

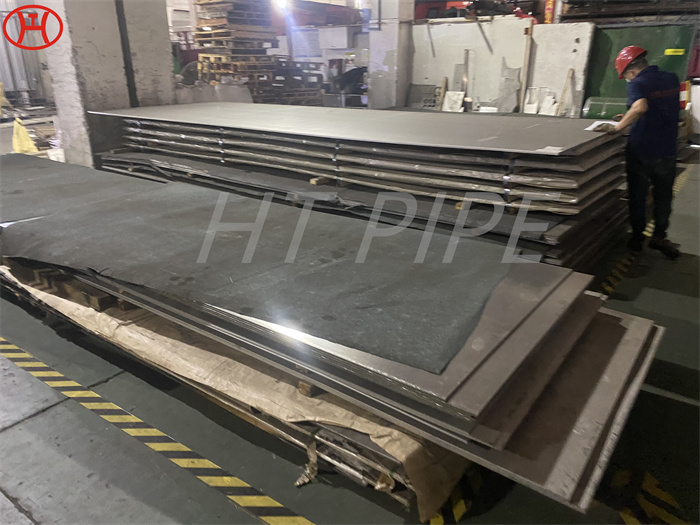

HT PIPE is one of the prominent 904L SS Pipe manufacturer, SS 904L pipes supplier and stockiest . The N08904 tubes are made available at the comprehensive range so that all applications demands can be well satisfied. To the respective buyers, the 1.4539 pipe is available at custom made specifications, standards, dimensions etc. It means a buyer can place the order to get these grade pipes in various wall thickness, length, types, schedules, sizes, end and forms etc as per their needs and requirements. The product is available at market leading rates. Since the carbon content of 904L thin wall stainless steel tube is very low (maximum 0.020%), there will be no carbide precipitation in the case of general heat treatment and welding.

This eliminates the risk of intergranular corrosion that occurs after general heat treatment and welding. Due to the high content of chromium, nickel and molybdenum and the addition of copper, 904L stainless steel welded pipe can be passivated even in reducing environments such as sulfuric acid and formic acid. The high nickel content makes it have a lower corrosion rate in the active state. In pure phosphoric acid in the concentration range of 0-85%, its corrosion resistance is very good. In the industrial phosphoric acid produced by the wet process, impurities have a strong influence on the corrosion resistance. Among all kinds of phosphoric acid, 904L stainless steel welded pipe has better corrosion resistance than ordinary stainless steel. Among the strong oxidizing nitric acid, 904L SS Pipe has lower corrosion resistance than high-alloyed steel without molybdenum. In hydrochloric acid, the use of 904L is limited to a lower concentration of 1-2%.

CHEMICAL PROPERTIES:

| Typical Chemical Composition % (max values, unless noted) | ||||||||||

| Grade | Cr | Ni | C | Si | Mn | P | S | Mo | Cu | Fe |

| 904L | min: 19 max: 23 |

min: 23 max: 28 |

0.02 Max | 1.0 max | 2.0 max | 0.045 max | 0.035 max | min: 4 max: 5 |

min: 1 max: 2 |

balance |

MECHANICAL PROPERTIES:

| Typical Room Temperature Mechanical Properties | |||||

| Grade | Tensile Strength

KSI (min.) |

Yield Strength 0.2% Offset KSI (min.) | Elongation % in 2ʺ(50.8 mm) | Hardness (Brinell) MAX |

Hardness (Rockwell B) MAX |

| 904L | 71 | 31 | 35 | 70-90 | 150 |