SS F310H Flange Stockist of SS UNS SS31008 Slip On Flanges

Though 310 is ideal for high temperature use, it should not be exposed to the severe thermal shock of repeated liquid quenching or where aqueous corrosive contaminants are present.

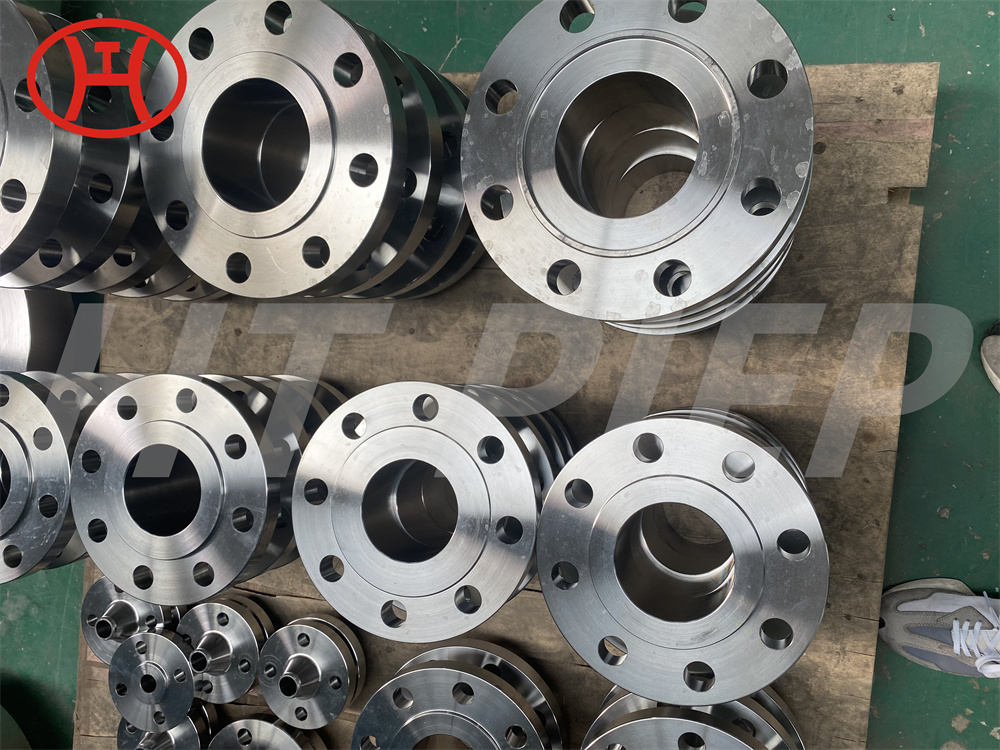

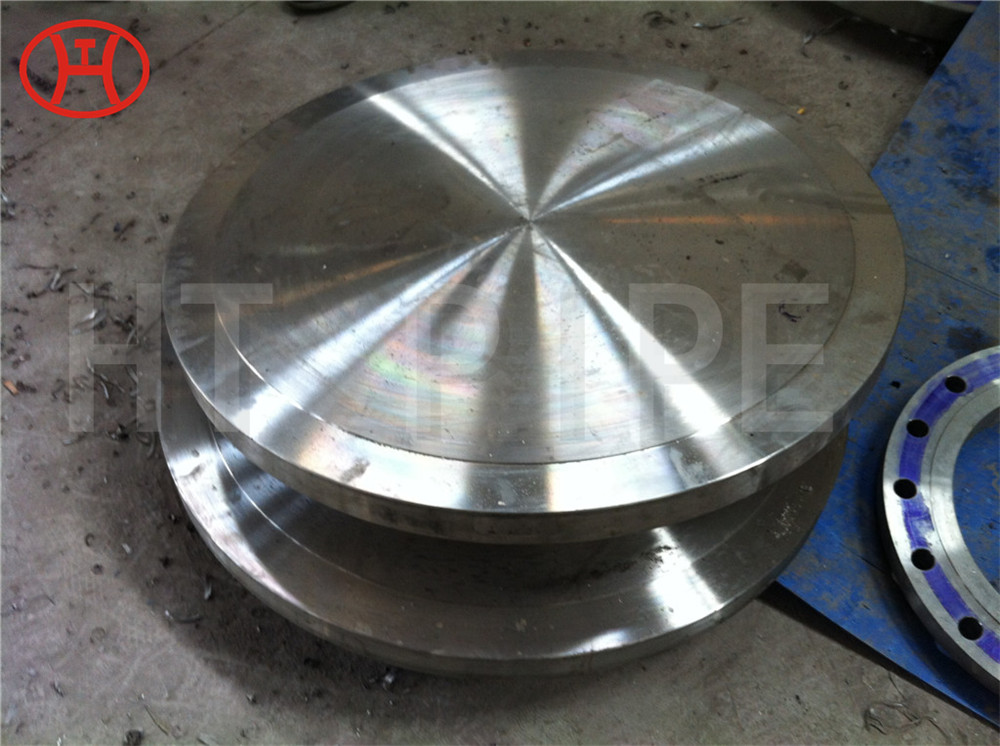

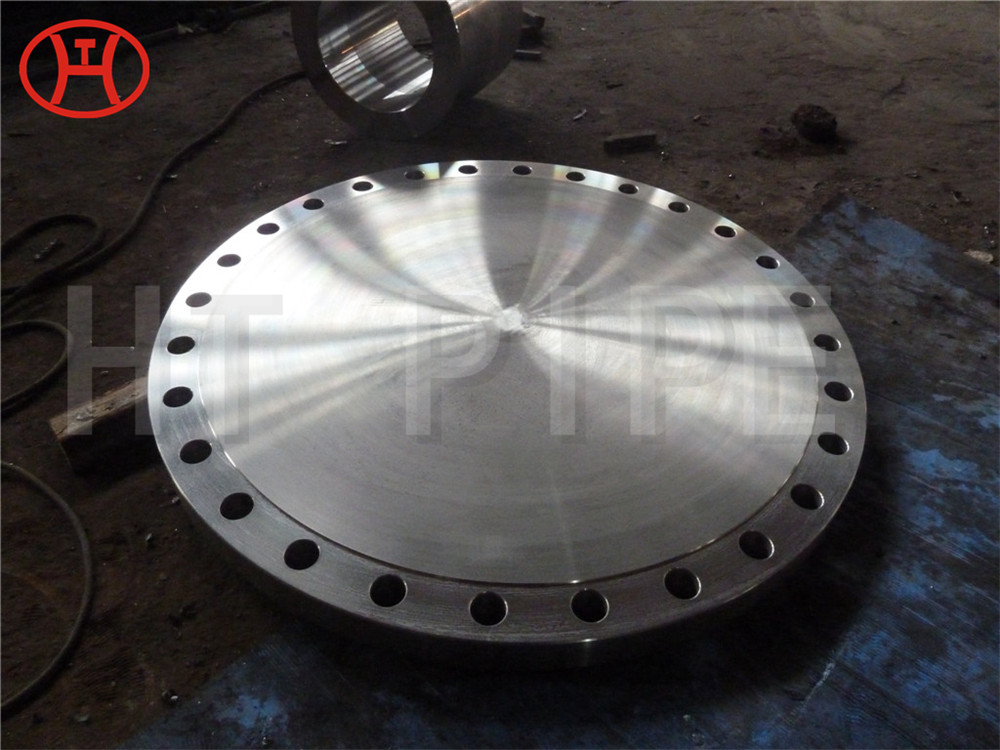

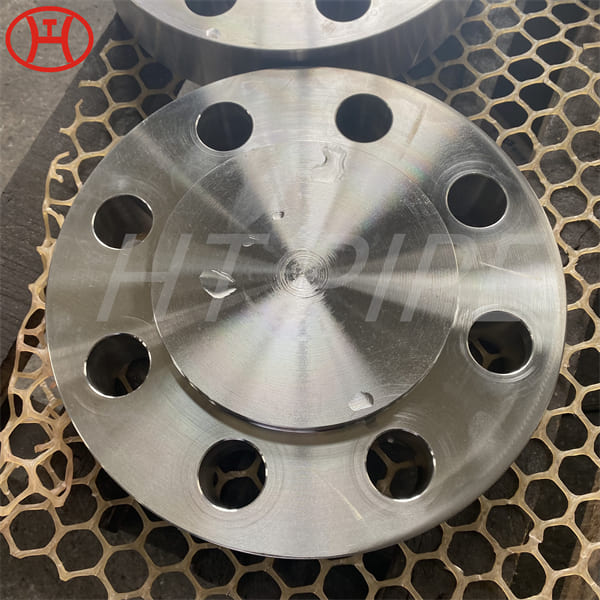

Manufacturer Of A182 310 SS Plate Flange, Werkstoff No 1.4841 SS Socket Weld Flanges, ANSI B16.5, ANSI B16.47, B16.48, BS4504, BS 10, EN-1092 Stainless Steel 310H Forged Flanges, 310H SS Lapped joint Flanges, Stainless Steel ASTM A182 F310 Threaded Flanges in China.

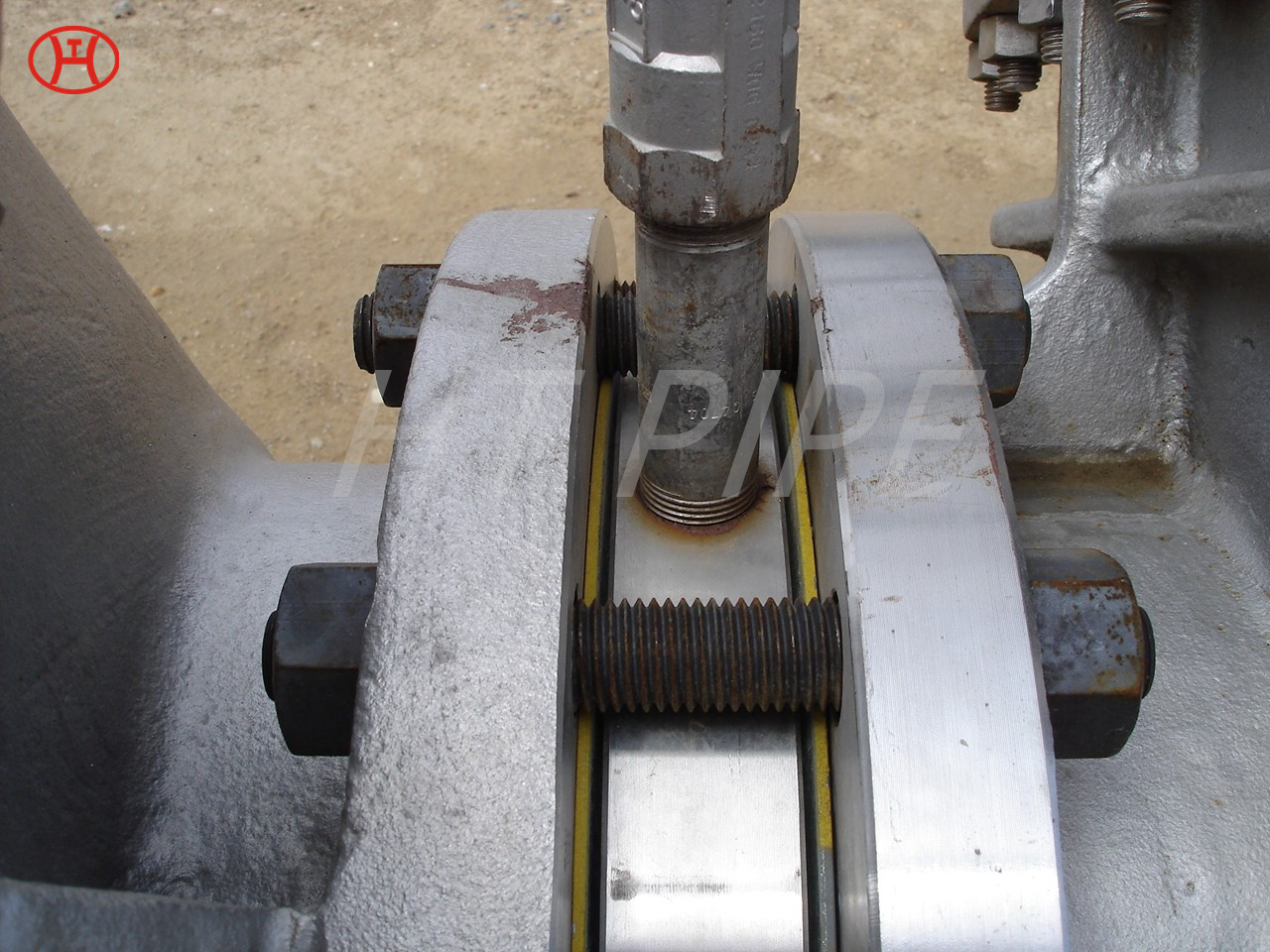

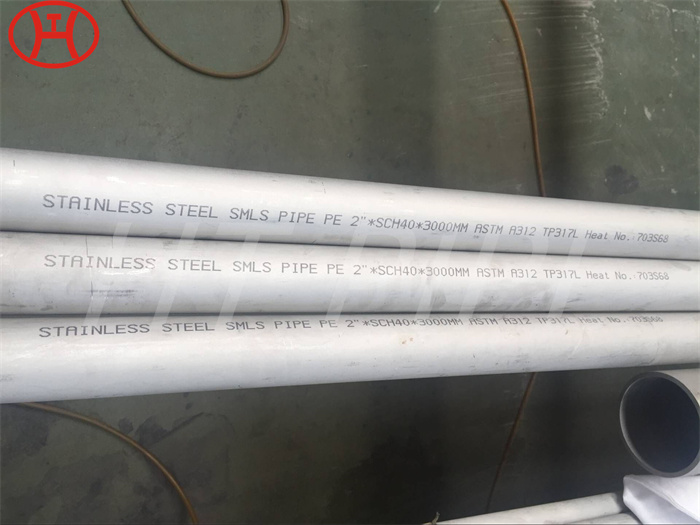

Stainless Steel 310 Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. SS Grade F310 Blind Flange also provides easy access for cleaning, inspection or modification. A182 F310 Threaded Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Stainless Steel 310 Flanges, combining excellent high temperature properties with good ductility and weldability, is designed for high temperature service. It resists oxidation in continuous service at temperatures up to 1150¡ãC provided reducing sulphur gases are not present. ASASME SA182 SS 310 Pipe Flange is also used for intermittent service at temperatures up to 1040¡ãC. Stainless Steel 310 Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Stainless Steel 310 Flanges, combining excellent high temperature properties with good ductility and weldability, is designed for high temperature service.

Stainless steel 310S flanges are high temperature resistant and have excellent oxidation resistance under mild cycling conditions, Good resistance to sulfidation and atmospheres encountered with sulfur dioxide gas at high temperatures. UNS S31008 flanges have good thermal fatigue resistance, excellent toughness down to -450¡ãF, low magnetic permeability, good ductility and weldability. Stainless Steel 310S Flanges (UNS S31008) is used when the application environment involves moist corrodents in a temperature range lower than that which is normally considered “high temperature” service. The lower carbon content of 310S does reduce its high temperature strength compared to 310. Like other austenitic grades these have excellent toughness, even down to cryogenic temperatures, although other grades are normally used in this environment. Grade 310 Stainless Steel Flanges is readily available for applications in the industrial, architectural, and transportation fields. Grade 310 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

ASME SA182 SS 310 Pipe Flanges Composition Standard

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

SS DIN 1.4841 Forged Flanges Mechanical Characteristics

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1402 °C (2555 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 40 % |