Stainless Steel 304H Flanges Manufacturer Supplier in China

AISI 304H is readily formed and fabricated through a full range of cold working operations.

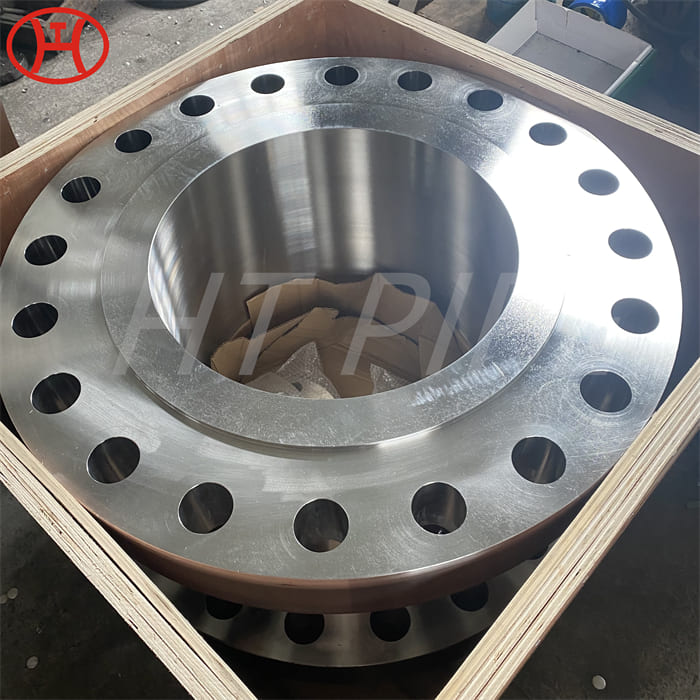

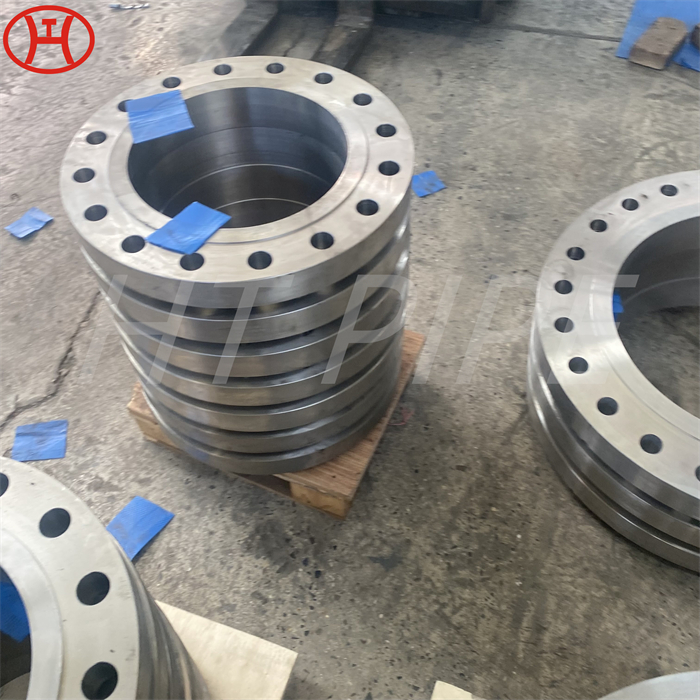

Global Supplier of SS 304H Weld Neck Flange, ANSI B16.5 SS 304H Orifice Flanges, DIN Standard Flanges, SS UNS S30409 Pipe Flanges, SS F304H Flange, Stockist of SS 304H Slip On Flanges, Stainless Steel 304H Flanges, SS 304H Blind Flanges Dealer in China.

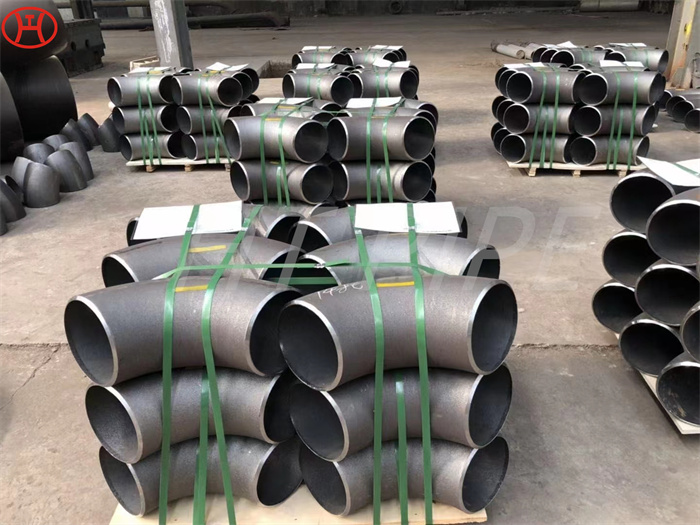

HT PIPE has been adding a new product to its product portfolio through harnessing advanced technology and our team of experts that studies market trends and formulates strategies to come up with products that are value-adding and cost-effective. You can choose from our vast array of reliable products. We are a manufacturer and supplier of Stainless Steel 304H Flanges, which are highly resistant to atmospheric corrosion. In moderately oxidising to moderately reducing environments, like the foods and beverages industry, SS 304H Weld Neck Flange is wise to use SS 304H Weld Neck Flanges as they show resistance to organic and inorganic chemicals. The considerably high content of Chromium and Nickel helps our ASTM A182 SS 304H Blind Flanges to function effortlessly in the nitric acid and acetic acid surroundings.

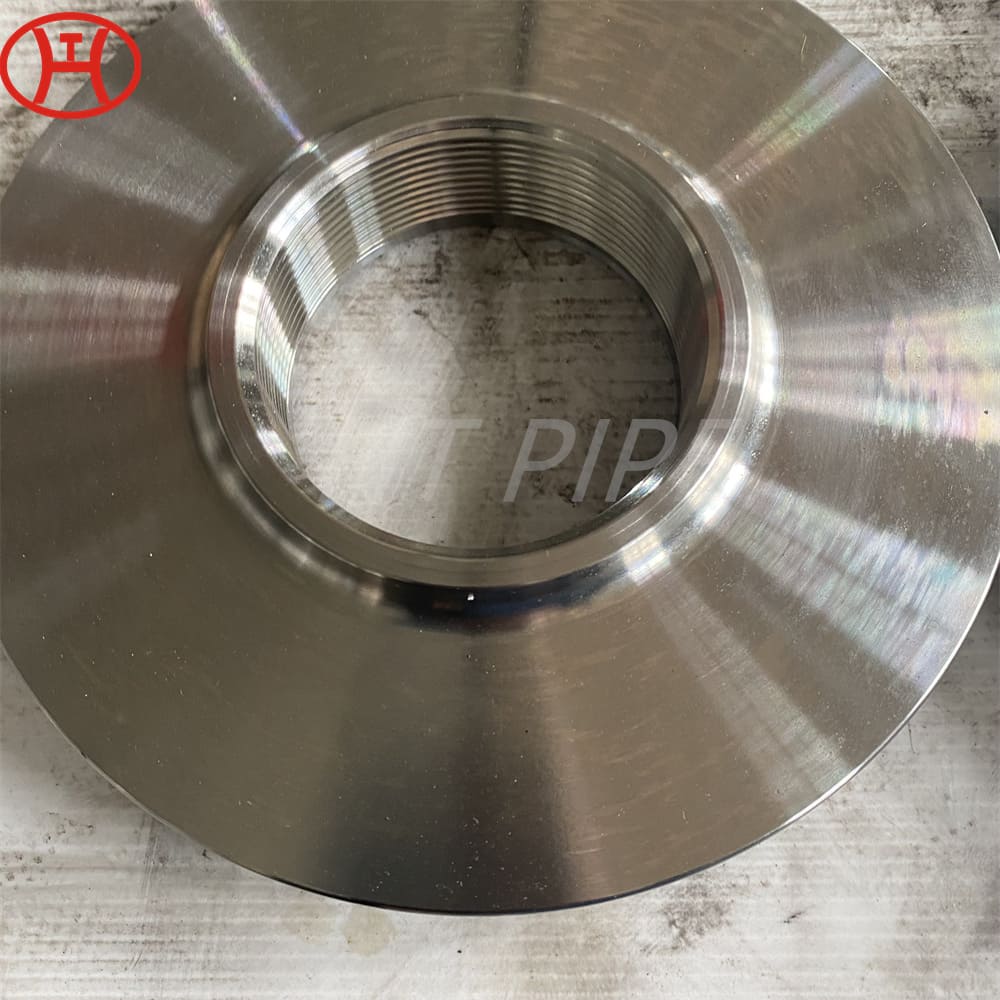

Hence, the petroleum refining and chemical processing industry relies on these ANSI B16.5 SS 304H Orifice Flanges. SS 304H Threaded Flanges perform extraordinarily in the sour service sector, as they are immune to highly reducing environs. Stainless Steel 304H Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. DIN Standard Flange also provides easy access for cleaning, inspection or modification. SS UNS S30409 Pipe Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. Grade 304 Stainless Steel is the standard “18/8” stainless; SS F304H Flange is the most versatile and most widely used stainless steel flange, available in a wider range of products, forms and finishes than any other. SS 304H Slip On Flange has excellent forming and welding characteristics. The balanced austenitic structure of Grade 304 enables StStainless Steel 304H Flange to be severely deep drawn without intermediate annealing, which has made this grade dominant in the manufacture of drawn stainless parts such as sinks, hollow-ware and saucepans. For these applications SSSS 304H Blind Flange is common to use special “304DDQ” (Deep Drawing Quality) variants.

Stainles Steel 304H Flange Range

| Stainless Steel 304H Flange Specification | ASTM A182 / ASME SA182 |

| Stainless Steel 304H Flange Manufacturing Process | Hot Forging / Rolling / Machining |

| Stainless Steel 304H Flange Other Grades | 202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. |

| UNS No. – UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 | |

| EN No. – 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539 | |

| Stainless Steel 304H Flange Outer Diameter | 1/2″ NB TO 64″ NB |

| Stainless Steel 304H Flange Pressure Class | Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement |

| PN 6, PN 10, PN 16, PN 25 and PN 40 etc | |

| Stainless Steel 304H Flange Schedule | Sch 10s TO Sch XXS or As Per Custom Requirement |

| Stainless Steel 304H Flange Facing | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Stainless Steel 304H Flange Dimension | ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631–2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc.. |

| Stainless Steel 304H Flange Types | Welding Neck Flange, Slip On Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Blind Flange, Orifice Flanges, Plate Flange, Long Welding Neck Flanges, Weldoflange, Nipoflange, Expander Flange, Reducing Flange, WNRF Flange, SORF Flange, SWRF Flange, Custom Flange as per Drawing etc. |

| Stainless Steel 304H Flange Other Testing | NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc. |

| Stainless Steel 304H Flange Value Added Services | Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

| Stainless Steel 304H Flange Packaging | Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps |

| Stainless Steel 304H Flange Shipment & Transportation | By Road – Truck / Train Partial Load, Full Load, By Sea – Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air – Freighter Civil Passenger and Cargo Planes |