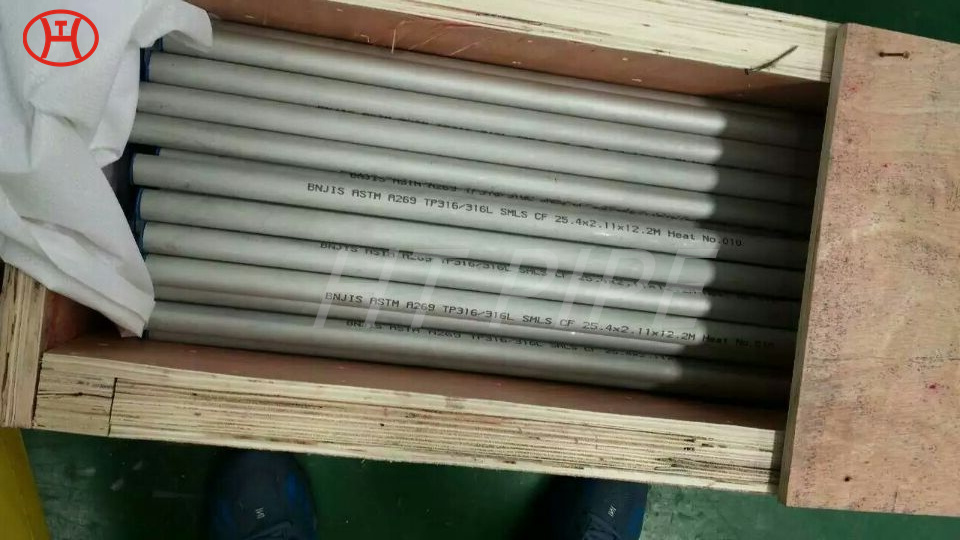

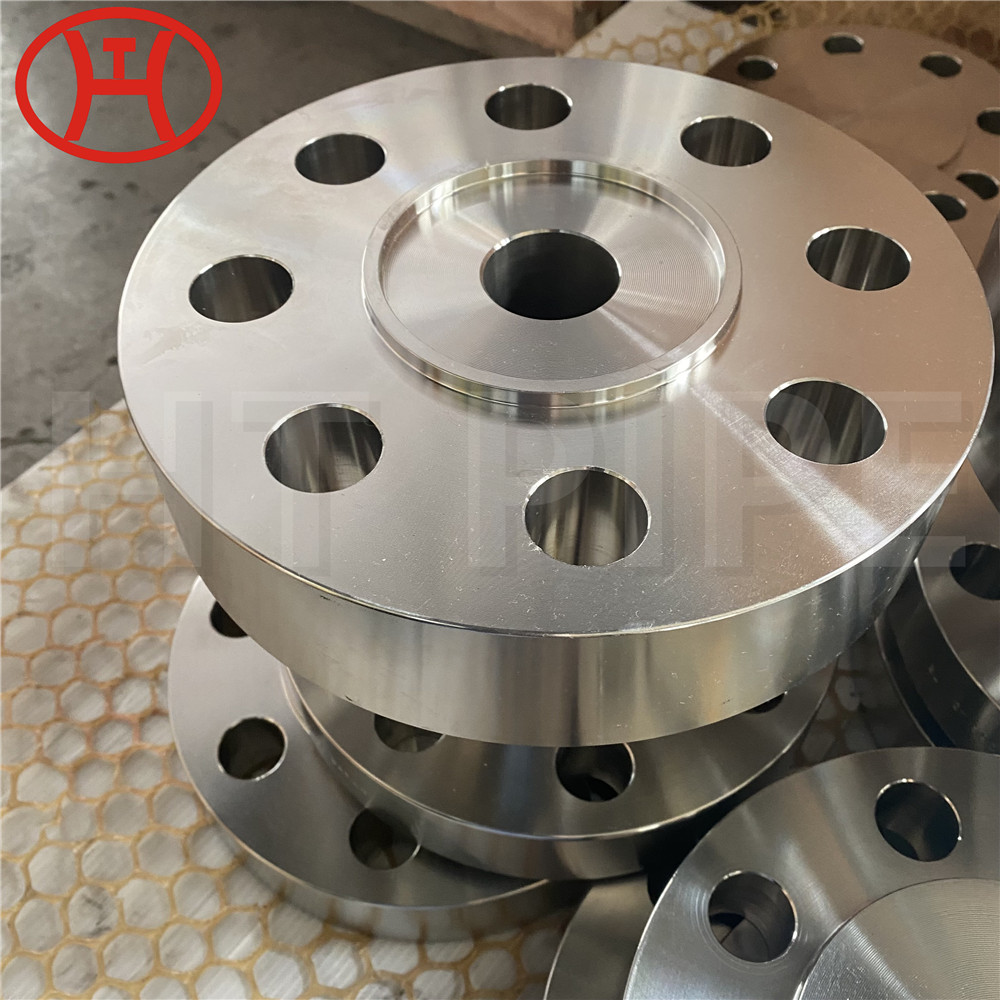

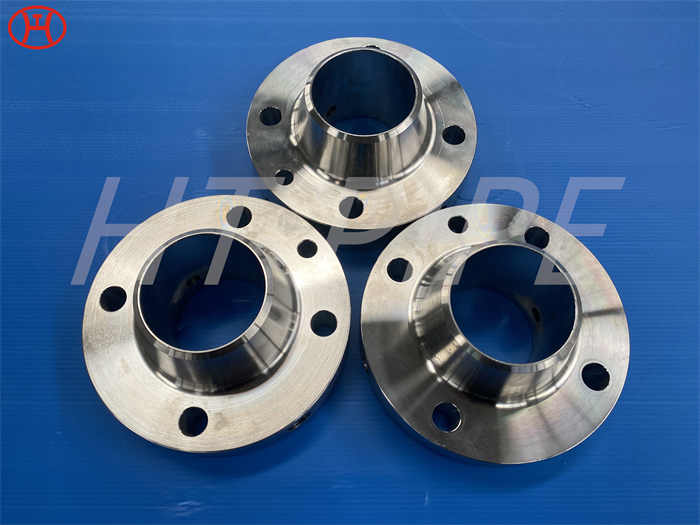

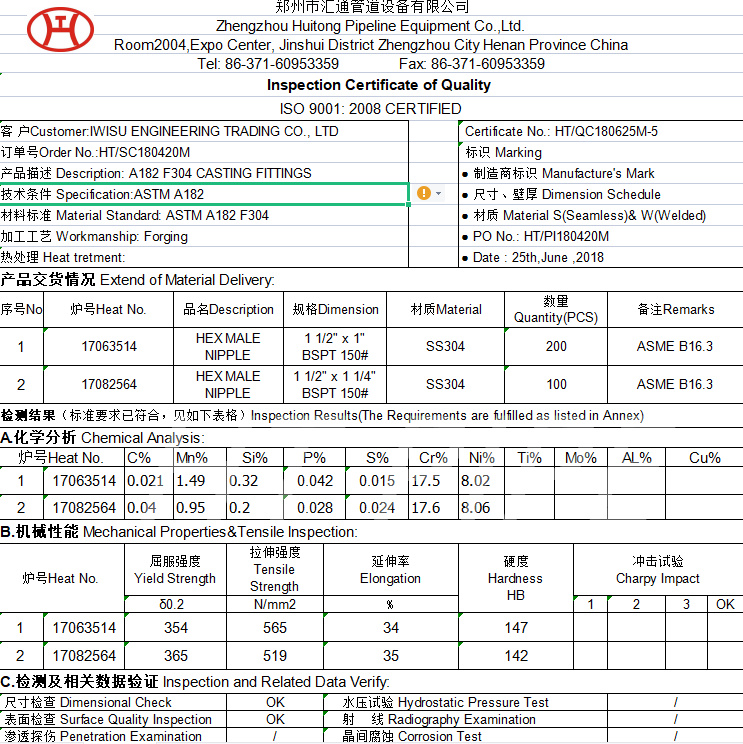

Stainless Steel 316 Corrosion Resistant Pipe Bend Pipe Fittings Manufacturers in China

The 316 stainless steel pipe bends can undergo processes, like cold forming and welding, where the austenitic crystal structure is transformed into ferromagnetic martensite. 316L steel is more susceptible to gaining some degree of magnetism.

The molybdenum makes the steel more resistant to pitting and crevice corrosion in chloride-contaminated media, sea water and acetic acid vapours. The lower rate of general corrosion in mildly corrosive environments gives the steel good atmospheric corrosion resistance in polluted marine atmospheres. It is also known for its high tensile strength and durability, making it a popular choice for applications where high strength and corrosion resistance are required. Type 316 is an austenitic stainless steel with added molybdenum which gives the alloy improved corrosion resistance. Type 316 (UNS 31600) is an austenitic chromium-nickel stainless steel alloy containing molybdenum. This addition increases corrosion resistance, improves resistance to pitting chloride ion solutions and provides increased strength at elevated temperatures.