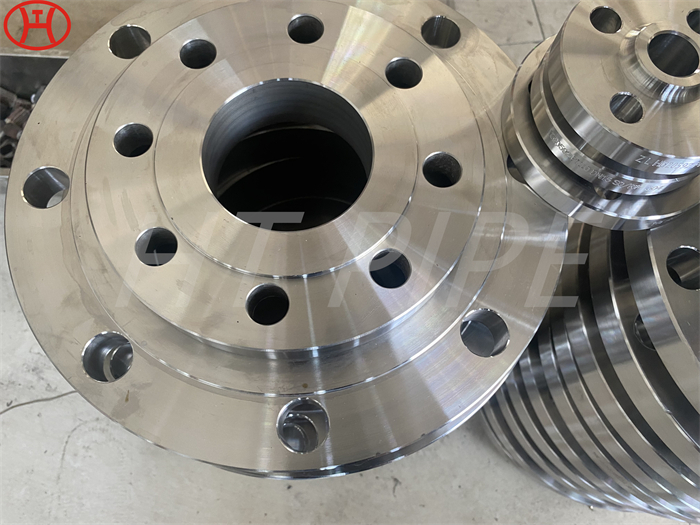

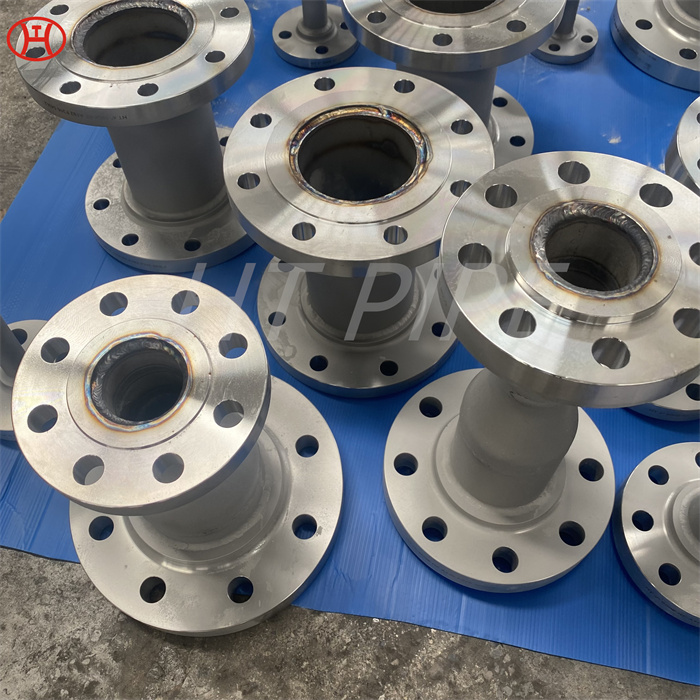

Stainless Steel F304 Flanges ASTM A182 SS F304 Socket Weld Flanges

Stainless Steel 304 Flanges are components that are used to connect pipes together. They differ from the fittings in that all flanges have an outward projection from them that provides additional space for attachment such as welding or bolting. Roopam Steel is a manufacturer and leading supplier of these flanges.

Stainless Steel F304 Flanges, ASTM A182 SS F304 Socket Weld Flanges, SS F304 Long Weld Neck Flanges, ASTM A182 F304 Stainless Steel Flanges, SUS F304 Pipe Flange Distributors, Stainless Steel Forged Flanges, SS UNS S30400 Flanges, ASTM A182 F304 WNRF Flanges, Stainless Steel F304 Slip on Flanges.

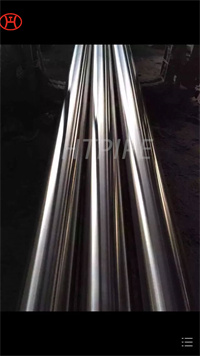

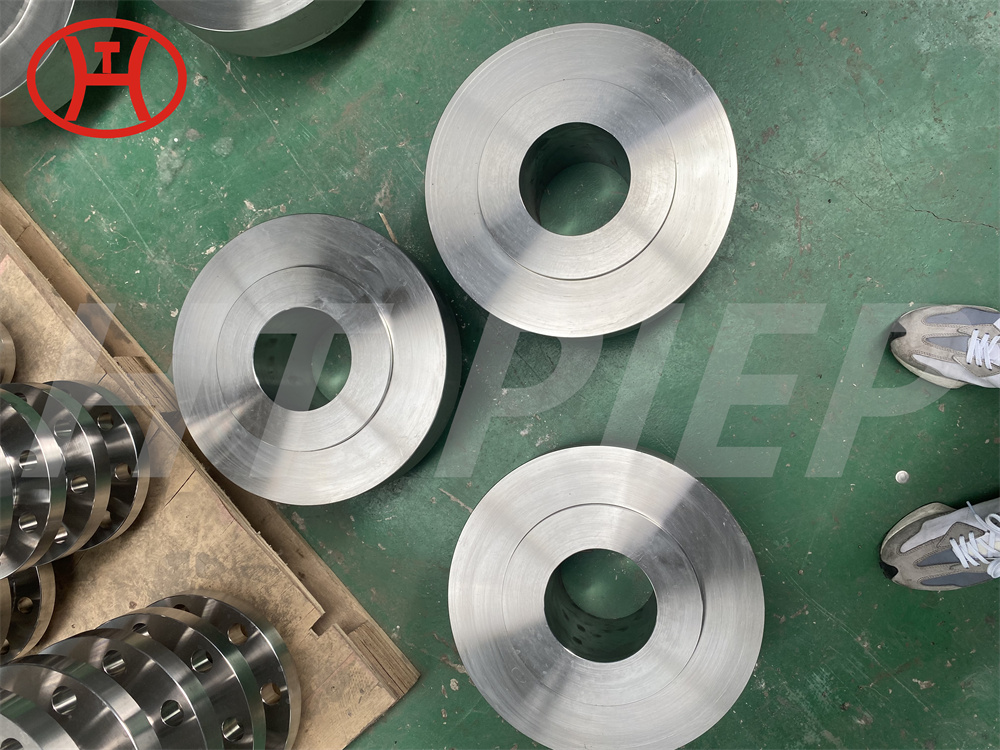

Stainless Steel 304 Flanges are some of the most commonly used grades of flange. These ASTM A182 SS F304 Socket Weld Flanges are used to connect two or more pipes or other piping components together. The ASTM A182 F304 Pipe Flanges are made up of the 304 austenitic stainless steel which is a chromium nickel alloy. SS F304 Long Weld Neck Flanges is stronger and has some extent of corrosion resistance in general purpose applications. The tensile and yield strengths of the material makes ASTM A182 F304 Stainless Steel Flange applicable for commercial, industrial and domestic applications. There are different types such as the A182 Gr F304 Slip on Flanges which are used to connect two pipes together by allowing the pipes to slip onto the flange. The ASME SA182 F304 Blind Flanges are used to seal the end of a pipe unlike the other flanges. The caps are important in piping to make sure a line is closed without leakages when necessary.

A182 F304 is a standard, austenitic 18/8 stainless steel grade. astm a182 grade f304 is one of the most versatile and most commonly used stainless steel grades today. SUS F304 Pipe Flanges are available in a wide range of fasteners and other components. SA182 F304 Stainless Steel Forged Flanges has excellent forming as well as welding properties. The balanced austenitic micro structure of 304 stainless steel flanges enables it to be severely deep drawn without the need for intermediate annealing. Which means that this stainless steel grade is dominant in the manufacture of drawn stainless parts in kitchen equipment’s such as sinks, hollow-ware and saucepans. Stainless steel 304 flanges can be readily braked or roll-formed into a various forms that are to be used for applications in the industrial, architectural, as well as transportation fields. SS 304 slip on flange also has outstanding welding characteristics. Post-weld annealing treatment in the ss 304 blind flange is not required while welding thin sections. Although Heavy welded sections in SS UNS S30400 Flanges may require a post-weld annealing treatment in order to achieve maximum corrosion resistance.

Specifications Of SS 304 Flanges

| Specification : | Stainless Steel 304 Flanges |

| Supporting Flange Material: | Flanges Bolts, Ring Joint, Gasket |

| Design For Size: | JIS Flanges, ANSI Flanges, BS Flanges, EN Flanges, ASA Flanges, ASME Flanges, DIN Flanges, PN Flanges |

| Common Types of SS Flange : | Flanges 150 LB WNRF |

| 600# BLRF | |

| Class 300 RTJ | |

| Class 900 SORF | |

| Size Chart : | 1/2″ (15 NB) To 48″ (1200NB) |

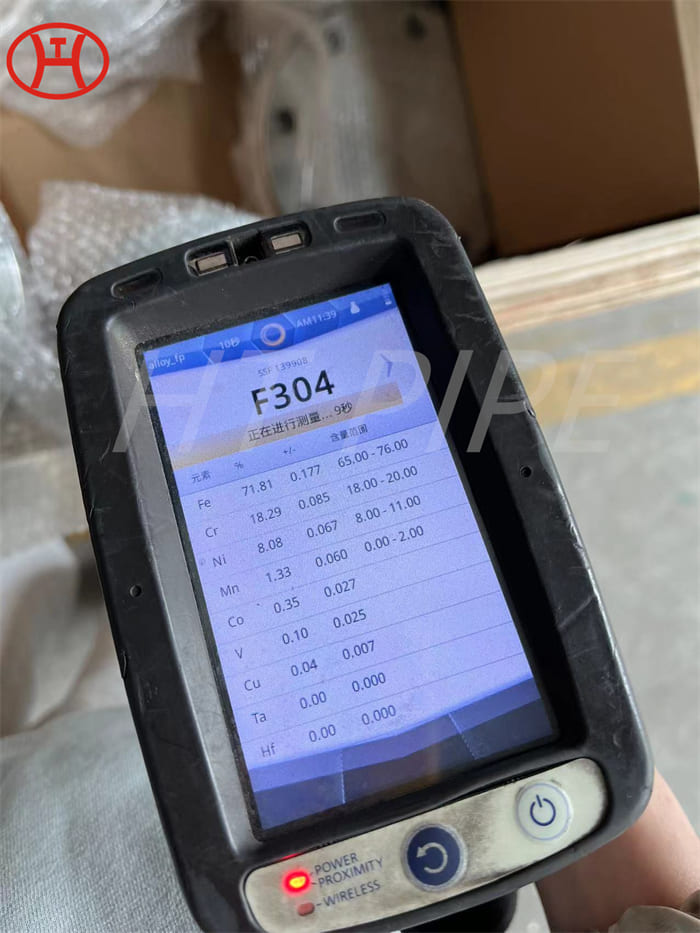

| Production Process: | Forged, Heat Treated and Machined |

| Stainless Steel 304 Flanges Coating Flange Faces : | Zinc Plated, Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized |

| Application: | Chemical Industry |

| Water Pipeline Industry | |

| Nuclear Power Plant | |

| Fabrication Industry | |

| Natural Gas Industry | |

| Oil And Gas Industry | |

| Standards: | JIS Flanges, ISO Flanges, GOST Flanges, UNI Flanges, AWWA Flanges, MSS SP44 Flanges, ASME B16.5 Flanges, ASME B16.38 Flanges, EN-1092 Flanges, BS10 Flanges, DIN Flanges, PN Flanges, ASME B16.47 (Series A, Series B) Flanges |

| Pressure Rating Table: | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Connect Type Type: | RF, FF, RTJ, LMF, SMF, LJF |

| Flange Machining Equipment: | Sand-blasting machine, Press machine, Bending machine, Pushing Machine, electric bevelling machine etc |