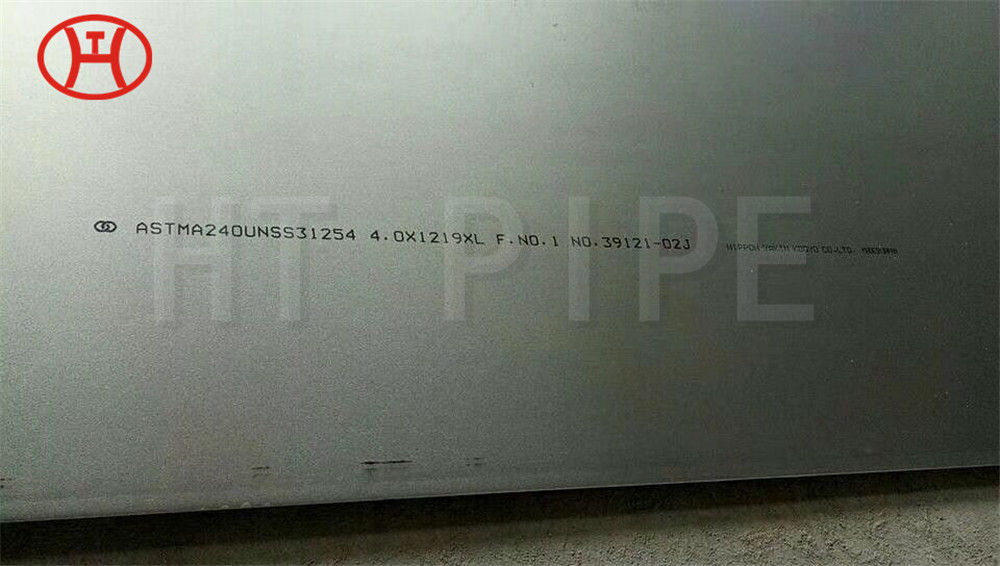

Stainless Steel Flange Incoloy 926 1.4529 UNS N08926 Alloy Flange

Incoloy 926 Stainless Steel Flange has high resistance to pitting and crevice corrosion when in Halide and H2S contained acid media

Alloy 926 Flange is more resistant to high temperature than traditional chromium-nickel stainless steel such as 304 ; The higher nickel content makes it have better oxidation resistance than the standard 18-8 stainless steel, and its oxidation resistance is not inferior to the higher grades whose service temperature is as high as 1900 F (1038 C) alloy. It is often used in pipelines, joints, air flow systems, etc. in acid gas production, components in flue gas desulfurization systems, evaporators, heat exchangers, filters, mixers, etc. in phosphoric acid production, sulfuric acid separation and condensation systems, concentration Evaporators and crystalline salts, condensation and piping systems in power plants using sewage cooling water, containers transporting corrosive chemicals, production of organic derivatives using acid chloride catalysts and reverse osmosis desalination plants.