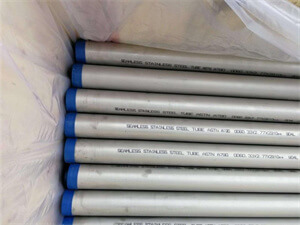

Stainless steel pipe 304l ss 304 sch 40 pipe thickness

304l stainless steel pipe has good machinability. Machining can be enhanced using the following rules: The cutting edge must remain sharp. Blunt edges can lead to excessive work hardening. The cuts should be light but deep enough to prevent work hardening on the surface of the material. A chip breaker should be used to help ensure that the chips remain concentrated at the cutting edge. This means that coolants and lubricants are required and must be used in large quantities.

304 is a general purpose stainless steel that is widely used to make equipment and parts that require a good combination of properties (corrosion resistance and formability). The lower carbon content minimizes carbide precipitation in the heat-affected zone near the weld, which can lead to intergranular corrosion (weld erosion) of stainless steel in some environments.

SA312 TP304 Pipe has good processability and weldability. Plate heat exchangers, bellows, household products (Class 1 and 2 tableware, cabinets, indoor pipelines, water heaters, boilers, bathtubs), auto parts (windshield wipers, mufflers, molded products), medical appliances, building materials, chemicals, food industry , agriculture, ship parts, etc. The SA312 TP304 Pipe with strictly controlled content can also be called food grade 304 stainless steel.

304/304L dual certified stainless is a very low carbon “18-8” austenitic chromium-nickel steel with good corrosion resistance and superior resistance to intergranular corrosion following welding or stress relieving. The low carbon content limits the formation of harmful carbides to such an extent that this grade may be safely used for most operations of welded construction, and where the service temperature is limited to 800° F. SA312 TP304 Pipe is non-magnetic in the annealed condition and not hardenable by heat treatment. Both hardness and tensile strength can be increased by cold working, which may cause slight magnetism.

APPLICATIONS

SA312 TP304 Pipe is used almost exclusively for parts requiring machining, welding, grinding, or polishing where good corrosion resistance is also required. It is a good general all-purpose stainless grade. Good in corrosive environments as in paper and chemical industries and cryogenic services. Used where corrosion resistance and good mechanical properties are primary requirements. SA312 TP304 Pipe is widely accepted in such industries as dairy, beverage, and other food industries where the highest degree of sanitation and cleanliness is of prime importance. Parts for handling acetic, nitric, and citric acids, organic and inorganic chemicals, dyestuffs, crude and refined oils, etc., are fabricated from this material. Because of its lack of magnetism it is highly desirable for instruments. 304 stainless pipe is also widely used for architectural trim.

Type 304 and 304L Stainless Steel Composition:

| Element | Type 304 (%) | Type 304L (%) |

| Carbon | 0.08 max. | 0.03 max. |

| Manganese | 2.00 max. | 2.00 max. |

| Phosphorus | 0.045 max. | 0.045 max. |

| Sulfur | 0.03 max. | 0.03 max. |

| Silicon | 0.75 max. | 0.75 max. |

| Chromium | 18.00-20.00 | 18.00-20.00 |

| Nickel | 8.00-10.50 | 8.00-12.00 |

| Nitrogen | 0.10 max. | 0.10 max. |

| Iron | Balance | Balance |