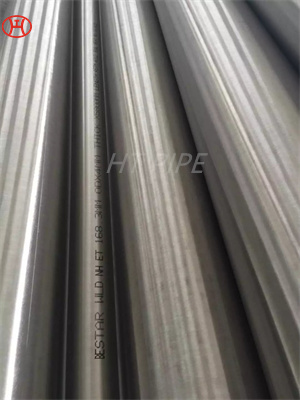

Stainless steel pipe 904L pipe diameter test

Stainless steel is an alloy of iron that is resistant to rusting. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel’s resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

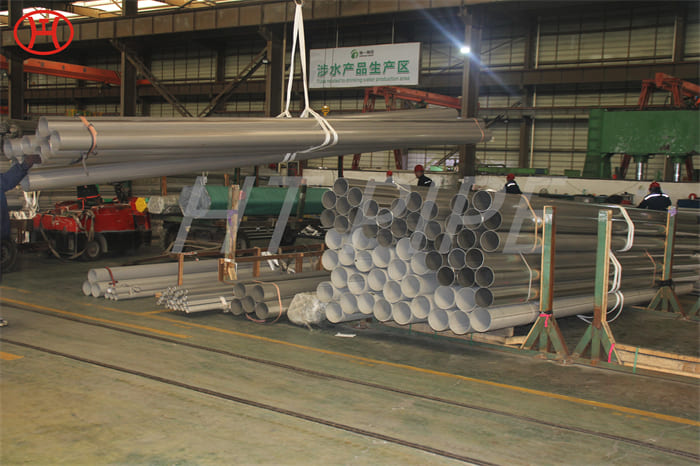

ASTM B677 TP 904L SS SEAMLESS PIPE MANUFACTURER, DISTRIBUTOR OF SS 904L WELDED PIPES

SS 904L Pipes are an acid resistant low carbon containing alloy grade. Aside from having a lower content of carbon in its alloy, these 904L Grade 1.4539 Stainless Steel Pipes are known to have a higher content of both nickel & molybdenum. Characteristically, the SS 904L Pipes demonstrates features such as good activation passivation conversion ability, along with an excellent resistance to corrosion. In fact, the corrosion resistance property of the SS 904L UNS N08904 Pipes are especially pronounced in non-oxidizing acids for e.g. acetic acid, sulfuric acid, formic acid, as well as phosphoric acid at any concentration and under normal pressure at any temperature.

We work really hard to maintain the quality of every material and ensure at every stage of its production by meticulous checks, tests, and controls with the help of our dedicated quality-control team. WNR 1.4539 Welded Pipes, ASTM B/ASME SB677 / B673 / B674 stainless steel pipe has a unique material composition within the 0.2 Carbon, 1.0 Si, 2.0 Manganese, 0.035 Sulfur, 0.045 Phosphorous, chromium 19-23, Nickel 23-28 shows a min. tensile strength of Psi – 75,000, MPa – 515 and a min. yield strength of Psi – 30,000, MPa – 205, and elongation in 35% in 50mm.Density 8.0 g/cm3, Melting point 1300-1390 ℃.

Grade 904L Stainless Steel Pipe Composition

| C % | Mn % | P % | S % | Si % | Cr % | Ni % | Mo % | N % | Cu % |

| 0.02 max | 2.00 max | 0.040 max | 0.030 max | 1.00 max | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.10 max | 1.00-2.00 |

AISI 904L Stainless Steel Pipe Mechanical & Tensile Strength

| Tensile Stress, Mpa | Yield Stress, MPa | Elongation, % |

| 490 min | 215 min | 30 min |