Stainless steel pipe ss 904L seamless steel pipe in stock

Astm A312 Tp 904l is also resistant to crevice corrosion and stress corrosion cracking. Stainless Steel 904l Seamless Pipe offers excellent formability and weldability and is said to be non-magnetic. Moreover, Astm A312 Tp 904l Welded Pipe is said to be resistant to chloride attacks and warm seawater.

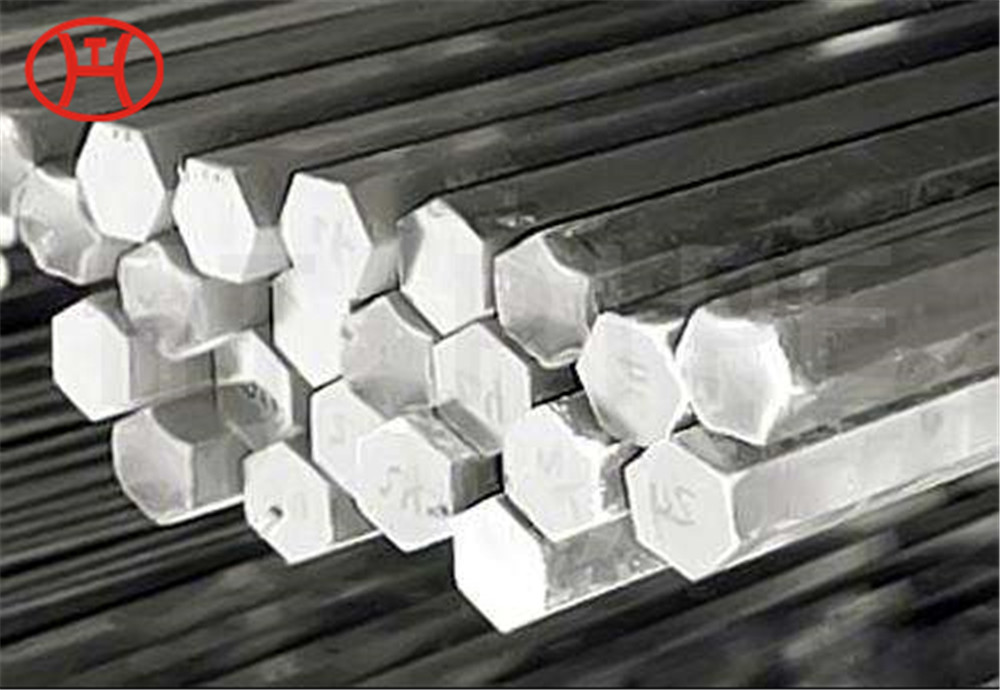

Stainless Steel 904L Square Pipes Manufacturers & Suppliers, SS 904L Seamless & Welded Pipes Available for Sale at Lowest Prices, UNS N08904/1.4539 Stainless Steel Square Pipes

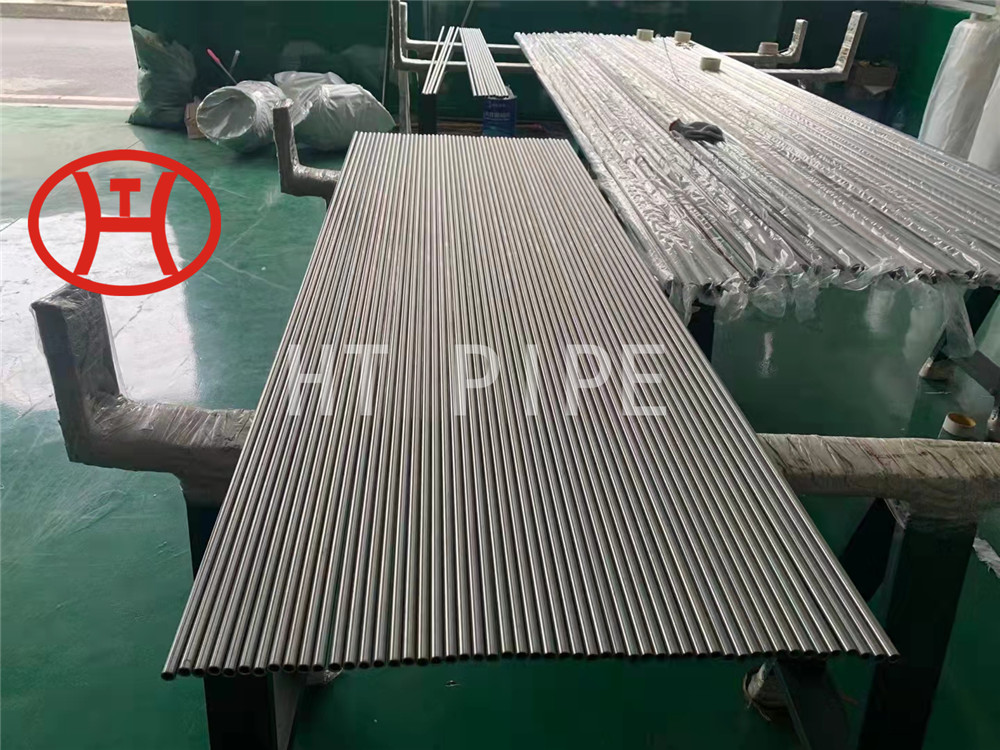

The UNS N08904 Seamless Pipe belongs to a super austenitic grade of non-stabilized stainless steel. Stainless Steel 904L Pipe is designed with an outstanding chemical composition of 19% to 23% of chromium with 23% to 28% of nickel and 4-5% of molybdenum. The content gives these UNS N08904 Seamless Pipes excellent resistance to corrosive and reducing media in different environments. The ASTM A213 TP904L Tubes work well in temperatures up to 400 degrees c where dilute sulfuric acid is present. These 1.4539 tubes can be readily used in aqueous conditions and can be welded in place following standard welding procedures. The AISI 904L Tubing exhibits outstanding toughness and formability. The 1.4539 tubes are generally cold-rolled via solution heat treatment procedures at temperatures between 1090 to 1175 degrees C.

UNS N08904 also known as 904L falls in the austenitic stainless steel group. ASTM A213 TP904L Tube has high molybdenum and extremely low carbon content. Copper content in the alloy greatly improves resistance to strong reducing acids, especially (H2SO4) sulphuric acid. 904L has better resistance. Ti chloride attack against both stress corrosion cracking and crevice / pitting corrosion. With excellent weldability and formability 904L also maintain non-magnetic state in all conditions. 904L provides excellent toughness , even down to cryogenic temperatures with its austenitic structure. The ASME SB 677 UNS N08904 Seamless Pipe is manufactured for use in high temperature and pressure applications. The high-strength ASME SB 677 904L pipes are designed without any welds or seams and are produced via the extrusion process. This gives these modules 20% higher load-bearing capacity when compared to the SS 904L Welded Pipe. But, a welded pipe is cheaper and takes lower processing time. These pipes are manufactured by welding pieces of sheet or strip in place following standard welding procedures.

We supply SS 904L Welded Pipe with MTC EN 10204/3.1B, compare our quality and price with other Stainless Steel 904L Pipe manufacturers in China

| Standard Specification | ASTM A312, ASTM A213, ASTM B677 |

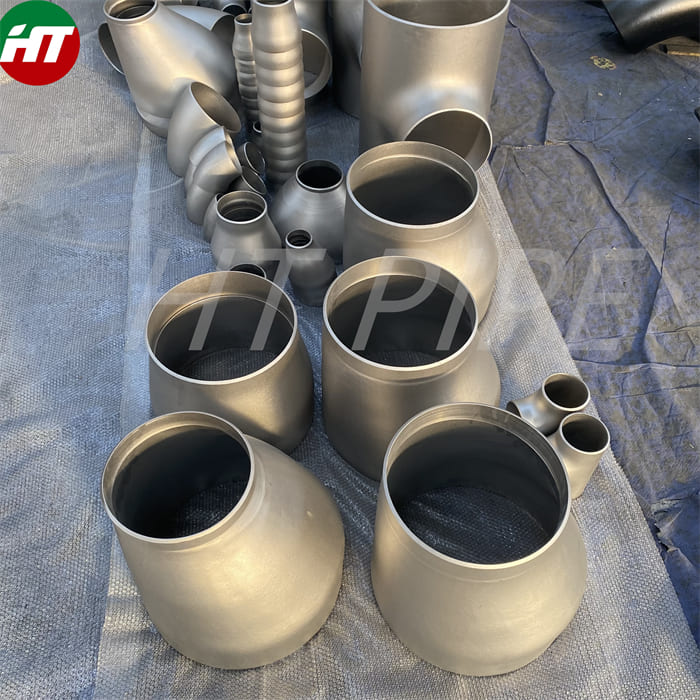

| Types | ERW, Seamless, Welded, EFW |

| Standard | DIN, JIS, AMS, GB, AISI, ASME, ASTM, EN, GOST |

| Size | OD: 4 to 219mm OD: 5.0 – 1219.2 mm OD: 5.0 – 1219.2 mm |

| Schedule Pipe Thickness Range | SCH 10, SCH 40, SCH 80, SCH 5, SCH XS, SCH XXS, SCH 160, SCH 80S Supplier in Mumbai |

| Surface Finish | Bright, Cold Finish, Annealing, Polished, Pickling |

| Technique | Cold Rolled Hot Rolled |

| Wall Thickness | 0.1 To 60 mm |

| Manufacturing Technology | Hot / Cold Formed |

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |