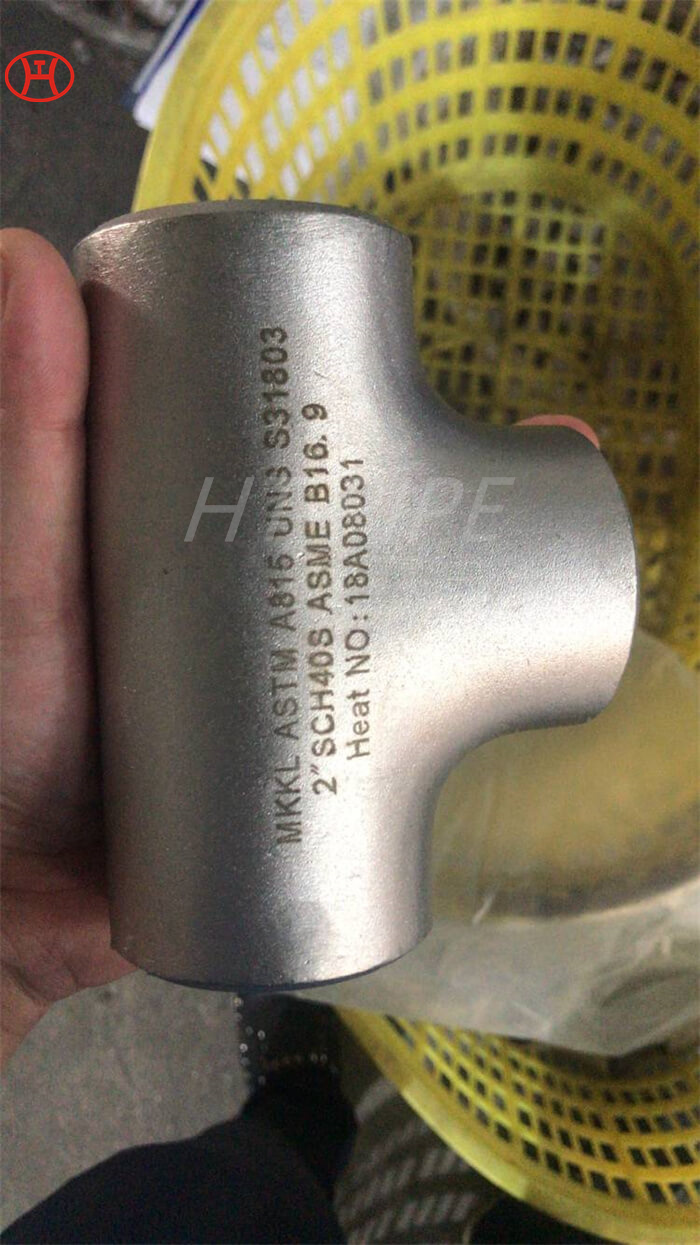

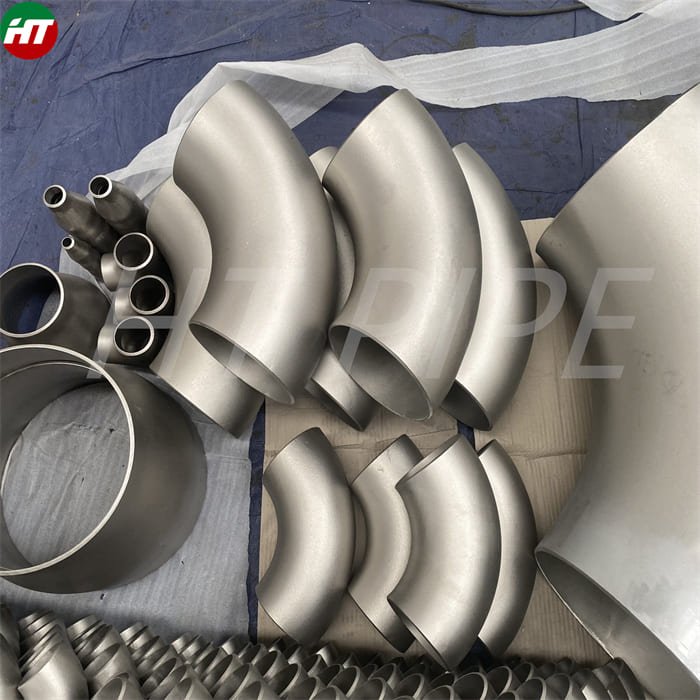

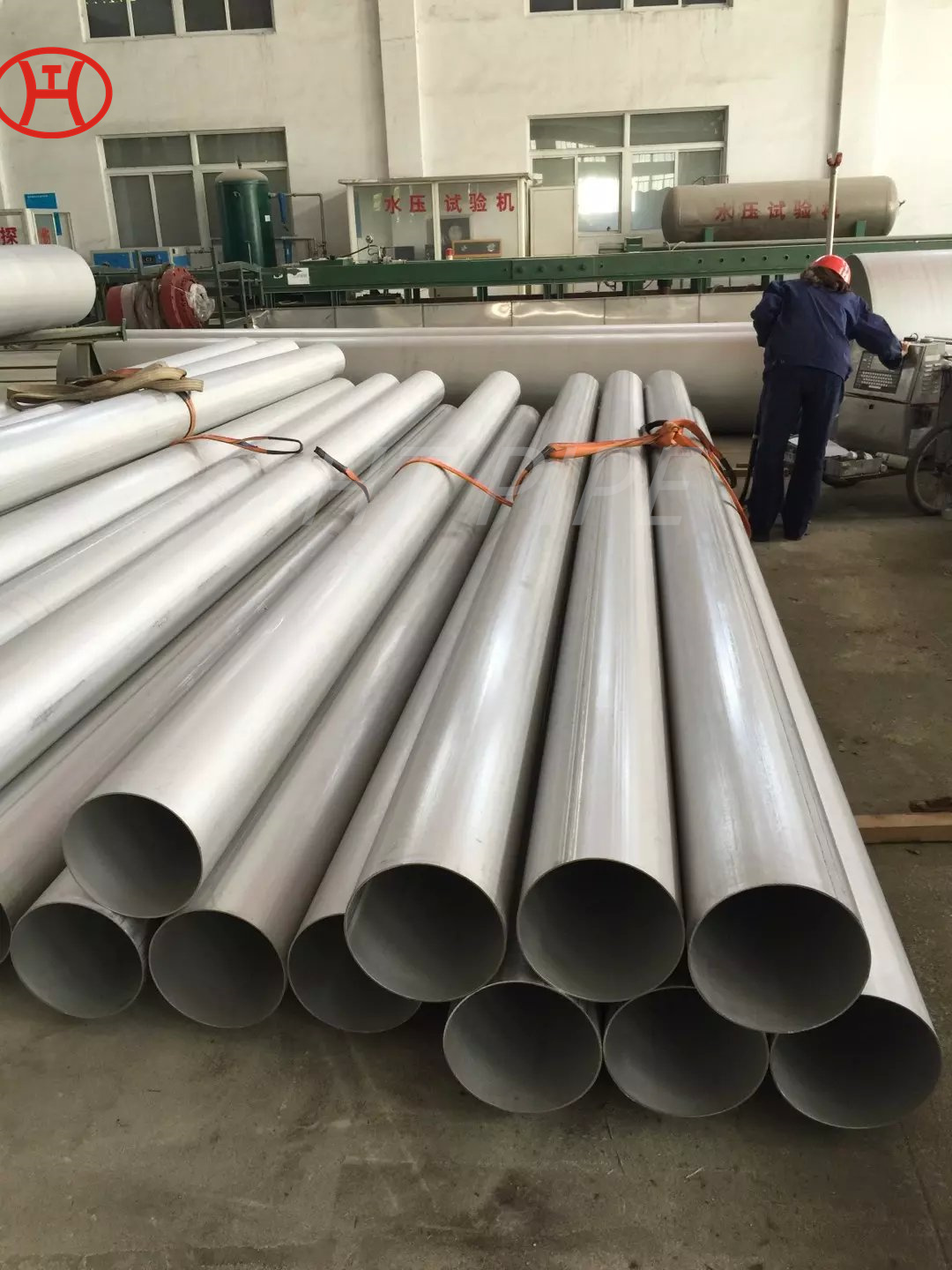

Stainless steel pipe fittings 304/316 male nipple hose

Stainless steel takes its name from its ability to resist rusting thanks to the interaction between its alloying components and the environment to which they’re exposed. Numerous types of stainless steel serve a variety of purposes and many overlap. All stainless steels are comprised of at least 10% chromium. But not all stainless steels are the same.

Type 304 Stainless Steel Nipple

Type 304 is the most widely used austenitic stainless steel. It is also known as “18/8” stainless steel because of its composition, which includes 18% chromium and 8% nickel. Type 304 stainless steel has good forming and welding properties as well as strong corrosion resistance and strength.

This kind of 304 Stainless Steel Nipple also has good drawability. It can be formed into a variety of shapes and, in contrast to type 302 stainless, can be used without annealing, the heat treatment that softens metals. Common uses for type 304 stainless steel are found in the food industry. 304 Stainless Steel Nipple is ideal for brewing, milk processing, and wine-making. 304 Stainless Steel Nipple is also suitable for pipelines, yeast pans, fermentation vats, and storage tanks.

Type 304 grade stainless steel is also found in sinks, tabletops, coffee pots, refrigerators, stoves, utensils, and other cooking appliances. It can withstand corrosion that can be caused by various chemicals found in fruits, meat, and milk. Other areas of use include architecture, chemical containers, heat exchangers, mining equipment, as well as marine nuts, bolts, and screws. 304 Stainless Steel Nipple is also used in mining and water filtration systems and in the dyeing industry.

Type 304L Stainless Steel

Type 304L stainless steel is an extra-low carbon version of the 304 steel alloy. The lower carbon content in 304L minimizes deleterious or harmful carbide precipitation as a result of welding. 304L can, therefore, be used “as welded” in severe corrosion environments, and it eliminates the need for annealing.

This grade has slightly lower mechanical properties than the standard 304 grade, but is still widely used thanks to its versatility. Like 304 Stainless Steel Nipple, it’s commonly used in beer-brewing and wine-making, but also for purposes beyond the food industry such as in chemical containers, mining, and construction. 304 Stainless Steel Nipple is ideal for use in metal parts such as nuts and bolts that are exposed to salt water.

| Chemical Composition | ||

| Chemical Composition (wt%) limits as specified in ASTM A240 and ASME SA240* | ||

| Element | 304 | 304L |

| Carbon | 0.07 | 0.03 max |

| Chromium | 17.5-19.5 | 17.5-19.5 |

| Nickel | 8.0-10.5 | 8.0-12.0 |

| Manganese | 2 | 2 |

| Silicon | 0.75 | 0.75 |

| Nitrogen | 0.1 | 0.1 |

| Phosphorus | 0.045 | 0.045 |

| Sulfur | 0.03 | 0.03 |

| * Maximum, unless range is indicated | ||

| Mechanical Properties | ||

| Mechanical property requirements for annealed product as specified in ASTM A240 and ASME SA240 | ||

| Property | 304 | 304L |

| Yield Strength, min. (ksi) | 30 | 25 |

| Tensile Strength, min. (ksi) | 75 | 70 |

| Elongation, min. (%) | 40 | 40 |

| Hardness, max. (Rb) | 92 | 92 |