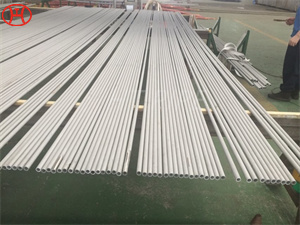

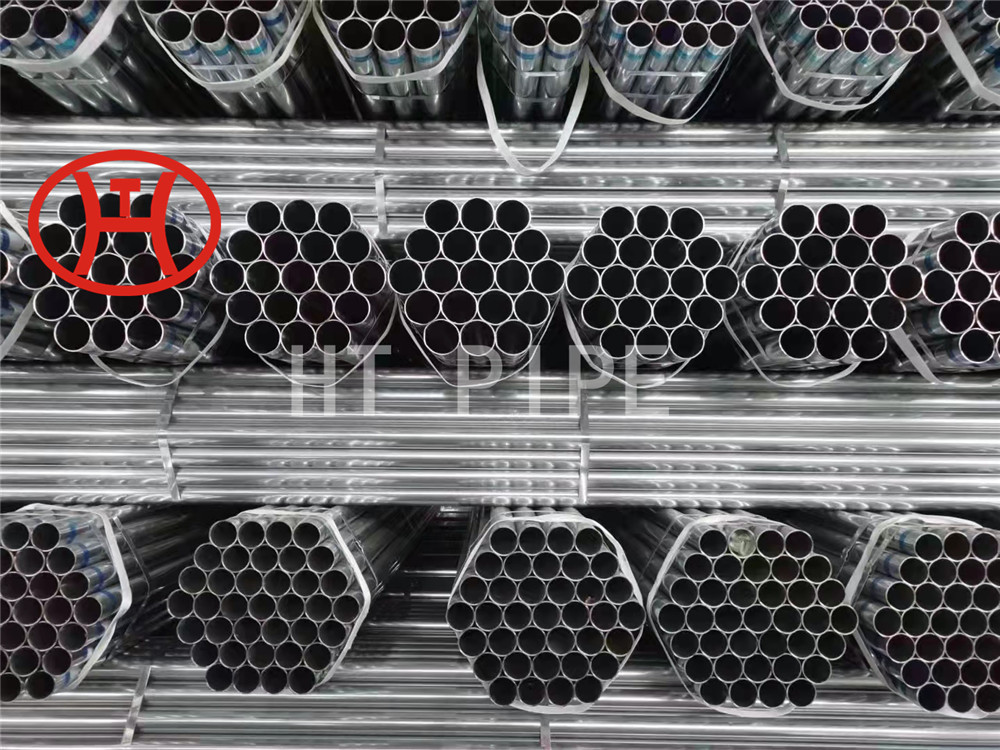

Stainless Steel pipe fittings 316 pipe bend for applications in the industrial architectural and transportation fields

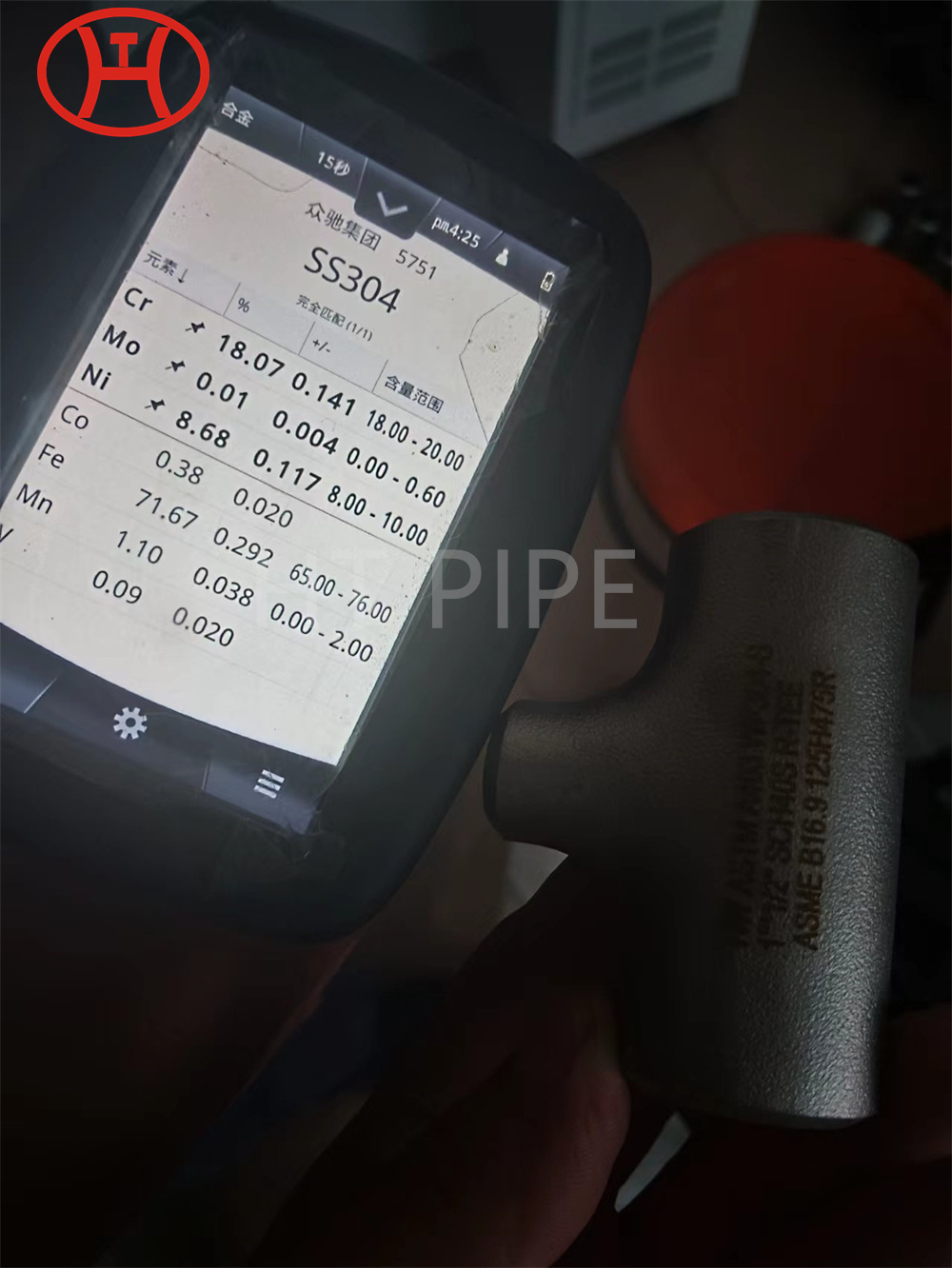

Stainless steel as a family of metals is very corrosion resistant but with the addition of molybdenum into 316, this increases the grades ability to withstand harsh environments. Often referred to as marine grade, 316 pipe bend is suitable for use in environments that are more aggressive than ambient although care should still be taken to clean the metal regularly to prolong its service life.

316/316L is the most commonly used austenitic stainless steel in the chemical process industry. The addition of molybdenum increases general corrosion resistance, improves chloride pitting resistance and strengthens the alloy in high temperature service. Through the controlled addition of nitrogen it is common for 316/316L to meet the mechanical properties of 316 straight grade, while maintaining a low carbon content. Properties of this austenitic stainless steel grade are similar to those of type 304 except that type 316 is somewhat stronger at elevated temperature ranges. In regards to formability, 304 stainless is usually a better option for forming operations because the higher molybdenum content in Grade 316 means that it possesses higher strength and work-hardening rates which can have adverse effects on formability. Type 316/316L is a chromium nickel austenitic stainless steel containing molybdenum. The molybdenum addition enhances the corrosion resistance over that of 304/304L in halide environments as well as in reducing acids such as sulfuric and phosphoric acid.