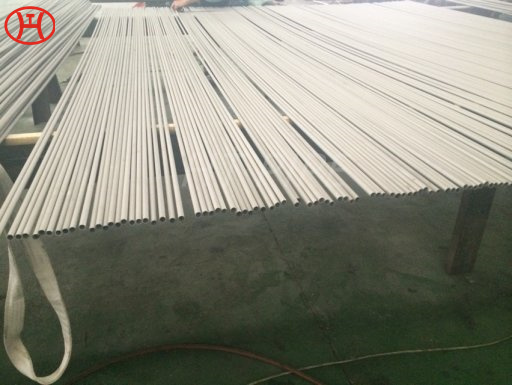

Stainless Steel pipe fittings 316 pipe bend ideal for outdoor applications in marine environments

316 is a member of the 18/8 chromium nickel family of austenitic stainless steels, with an addition of 2% molybdenum for improved corrosion resistance, particularly to localised corrosion in chloride containing environments.

316 Stainless sheet is widely used in marine and highly acidic environments, underwater equipment, surgical tools, food and pharmaceutical applications. 316 stainless steel is similar in chemistry to 304 but also includes molybdenum. That addition makes it much more corrosion resistant. Like 304, the 316 formula does not require post-weld annealing. 316L stainless steel is almost identical to 316. The only difference is the carbon content. 316L¡¯s lower carbon content imparts even better corrosion resistance than 316. 316L does not require post-weld annealing. 316 stainless steel bar, also known as UNS S31600 and Grade 316, is an austenitic stainless steel whose major alloying elements include chromium, nickel and molybdenum. The addition of molybdenum (not found in Stainless Steel 304) is the component which gives Stainless Steel 316 increased resistance in highly corrosive surroundings such as salt water or chloride environments.