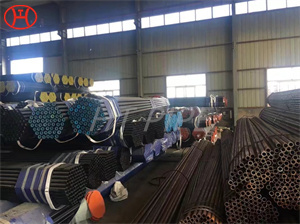

Stainless Steel pipe fittings 316 pipe bend of ANSI ASME and DIN standards in chloride environments

316 stainless steel pipe bend contains an addition of molybdenum that gives it improved corrosion resistance. This is particularly apparent for pitting and crevice corrosion in chloride environments.

Corrosion resistance is improved, particularly against sulfuric, hydrochloric, acetic, formic and tartaric acids, as well as corrosion caused by acid sulfates and alkaline chlorides. Because of its superior corrosion and oxidation resistance, good mechanical properties and fabricability, CS 316 has applications in many sectors of industry. Type 316 stainless can be found in heat exchangers, pharmaceutical equipment, dairies and breweries, marine fittings, coastal architectural fascia and fittings and in food preparation areas. Supra range Cr-Ni-Mo austenitic stainless steels have excellent corrosion resistance, welding and forming, especially stretch-forming characteristics. Austenitic steels exhibit very high ductility also down to cryogenic temperatures. Due to the higher toughness and work hardening nature of austenitic stainless steels, special attention may be needed during forming and machining compared to ferritic stainless or carbon steels.