Stainless steel pipes and tubes of 254smo 1.4547

254SMO (UNS S31254) is an austenitic stainless steel compatible with common austenitic stainless steels, designed with high levels of chromium, molybdenum and nitrogen for maximum resistance to pitting and crevice corrosion.

254 SMO Pipe Suppliers | WNR 1.4547 Tubing | 254 SMO Seamless Pipe Suppliers | 254 SMO Welded Pipe Suppliers | 254 SMO ERW Pipe Manufacturers | 6Mo Pipe Suppliers | ASTM A312 UNS S31254 Pipes

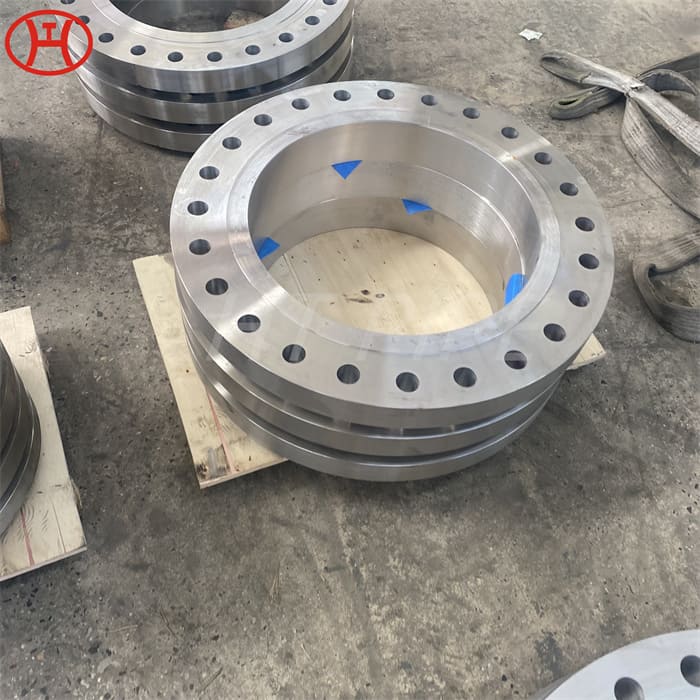

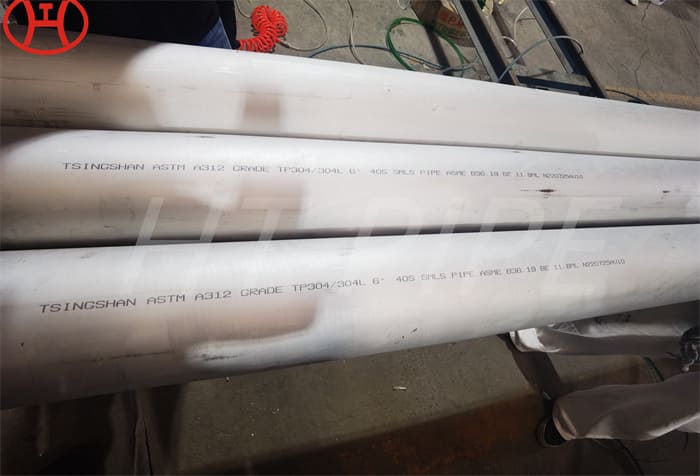

254 SMO Seamless Pipes with UNS S31254 and WNR 1.4547 supplied by HT PIPE is a high quality Alloy 254 SMO Seamless Pipe offeres in forms like 254 SMO Round Pipe, 254 SMO Square Pipe and 254 SMO Rectangular Pipe. UNS S31254 Seamless Pipes are manufactured using quality stainless steel material in different wall thickness and diameters. We manufacture Stainless Steel 254 SMO Seamless Pipes in forms like SMO 254 Round Pipe, SMO 254 Square Pipe and SMO 254 Rectangular Pipe.

254 SMO Seamless Pipe supplied by HT PIPE are widely used in various industrial applications. UNS S31254 Seamless Pipes are available in various sizes and shapes, custom sizes are also available as per clients requirement. 254 SMO is much stronger than regular austenitic grades, but also features high ductility and impact strength. ASTM A312 UNS S31254 tubing is often referred to as a “6 molybdenum” grade due to its molybdenum content, which is able to withstand high temperatures and maintain strength in volatile conditions.

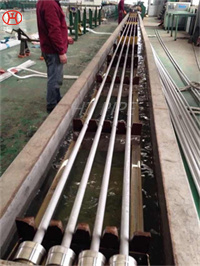

UNS S31254 or DIN W.Nr. 1.4547, 254SMO is a Cr-Ni-Mo alloy super austenitic stainless steel with deliberate addition of copper and nitrogen content. 254SMO contains high levels of Chromium, Molybdenum and Nitrogen, making WNR 1.4547 especially suitable for high chlorine environments and provides better chlorine resistance than Alloy 904L, SS316L, Alloy 20 and Alloy 825. 254 Smo Tubing is widely used in saltwater handling, chemical processing, food processing, and petroleum production. Tubo WNR 1.4547 is also used in pulp mill bleach systems, flue gas desulfurization, scrubber, and tall oil distillation columns. HT PIPE 254 Smo Tubing can be formed by pressing, forging, casting, and pushing. ASTM A312 6mo Efw Tubing can only be hardened via the process cold reduction.

Specification:

| Standard | ASTM A 269 ASME SA 269, ASTM A 249 ASME SA 249, UNS 31254 piping |

| Seamless Pipe Size | 3.35 mm OD To 101.6 mm OD |

| Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg |

| Pipe wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Length | Single Random, Double Random, Standard & Cut length pipe |

| Finish | Polished, Annealed & Pickled (AP), Bright & Annealed (BA), MF |

| Form | U-bent or Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc. |

| Type | Seamless, ERW, EFW, Welded, Fabricated pipes |

| End | Plain End, Beveled End, Treaded pipes |