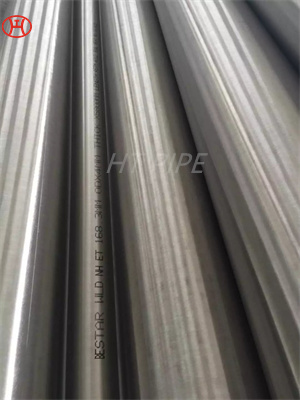

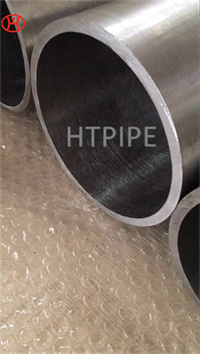

stainless steel pipes and tubes of S31254 Z1 CNDU 20.18.06Az

254SMO is non-magnetic, may be easier to weld, and has a wider operating temperature range when used with super duplex stainless steel. However, due to its higher nickel and molybdenum content, it is much more expensive and much less strong.

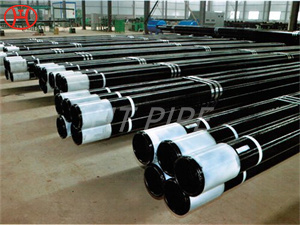

SMO 254 welded pipe was developed for use in halogenated environments such as seawater. 254 SMO seamless tubing has excellent resistance to a wide range of atmospheric environments and many corrosive media. Alloy 254/254 SMO/6 Mo tube, also known as 18/8 stainless steel, is the most common stainless steel.

254SMO and other super austenitic materials have been specified for marine scrubbers because their intermittent use can result in operating temperatures >250¡ãC. However, super duplex stainless steels have been successfully used in FGD systems in power stations because continuous operation results in lower temperatures. In water treatment systems such as RO/desalination, super austenitic steels such as 254SMO have been replaced by super duplex stainless steels.