Stainless steel pipes of 254smo S31254

254SMO made of high concentration of molybdenum, chromium and nitrogen has good resistance to pitting and crevice corrosion. Copper improves corrosion resistance in certain acids. In addition, 254SMO has good stress strength corrosion cracking properties due to its high content of nickel, chromium and molybdenum.

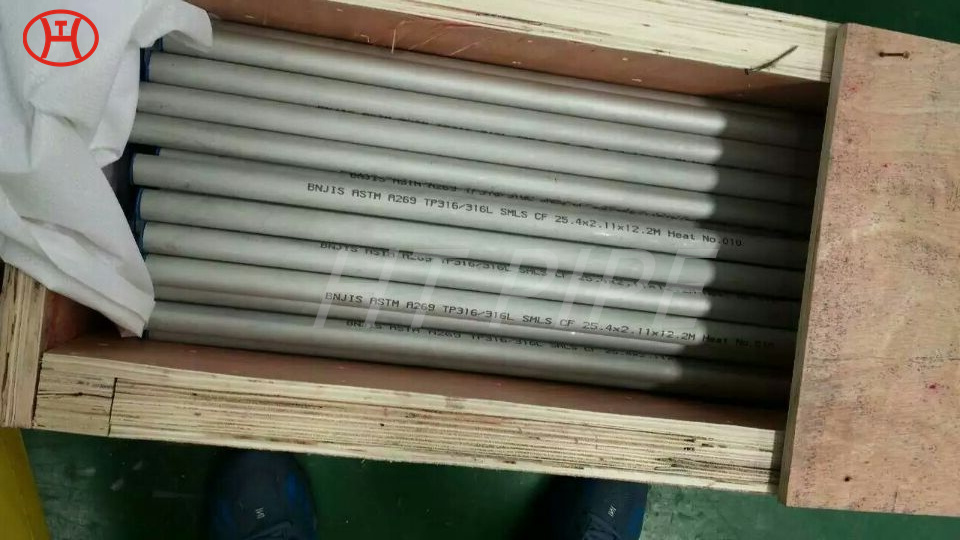

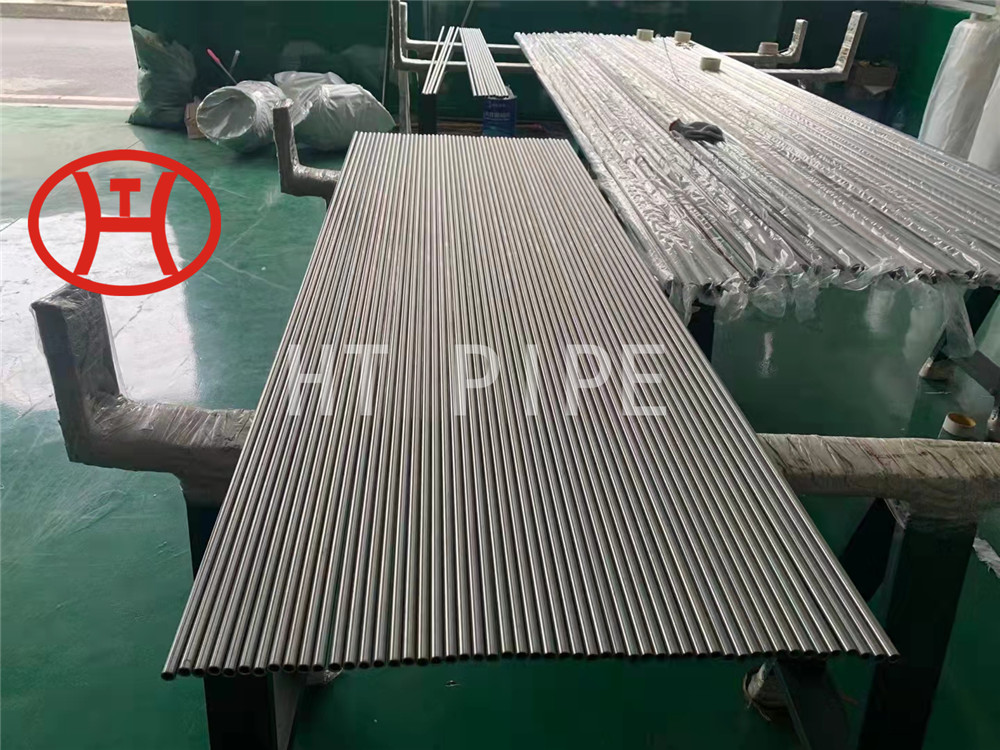

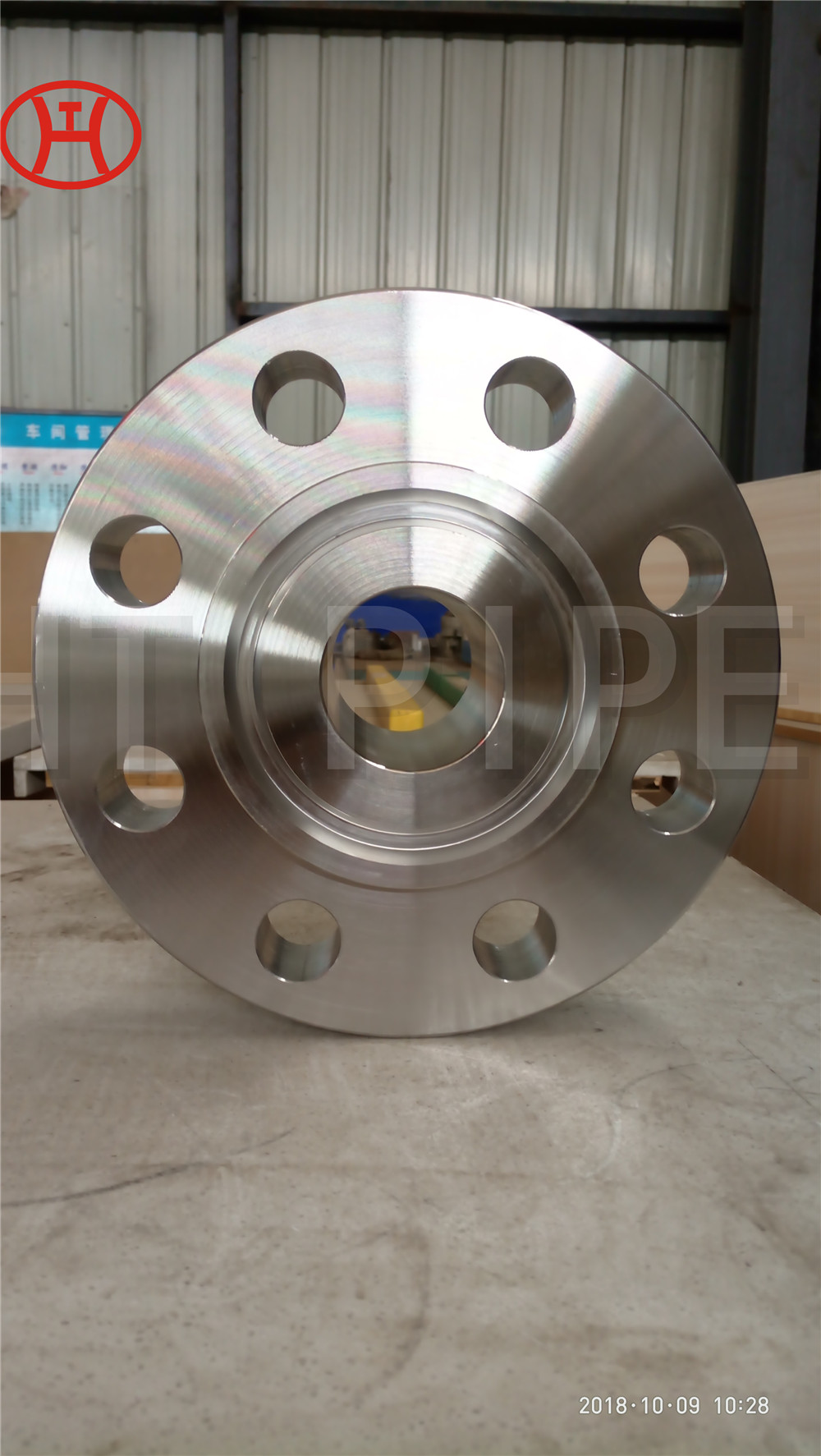

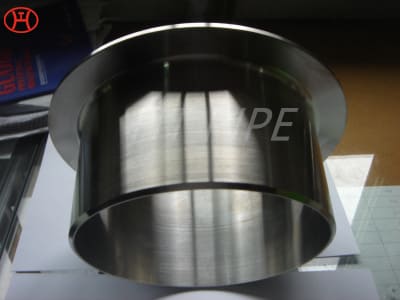

254SMo Tubing 254SMo Pipe S31254 Tubing 6MO Seamless Tubing Pipe

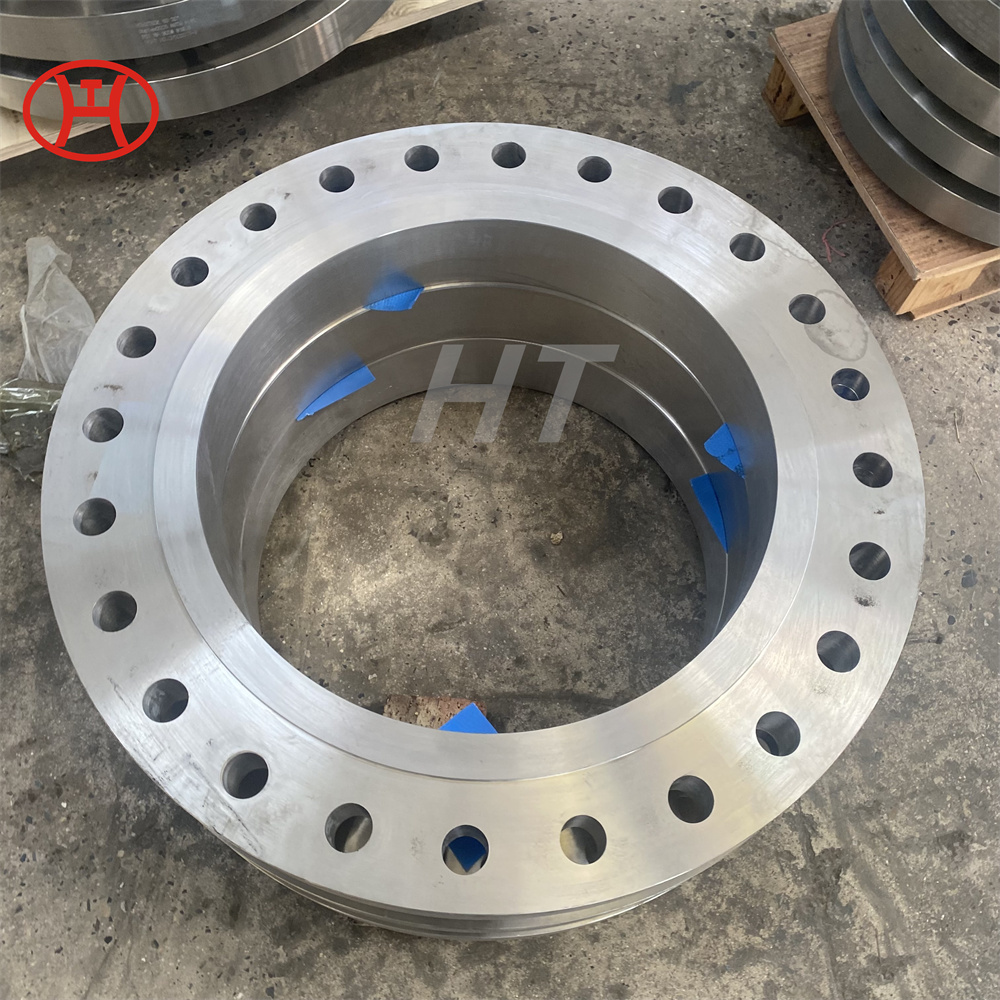

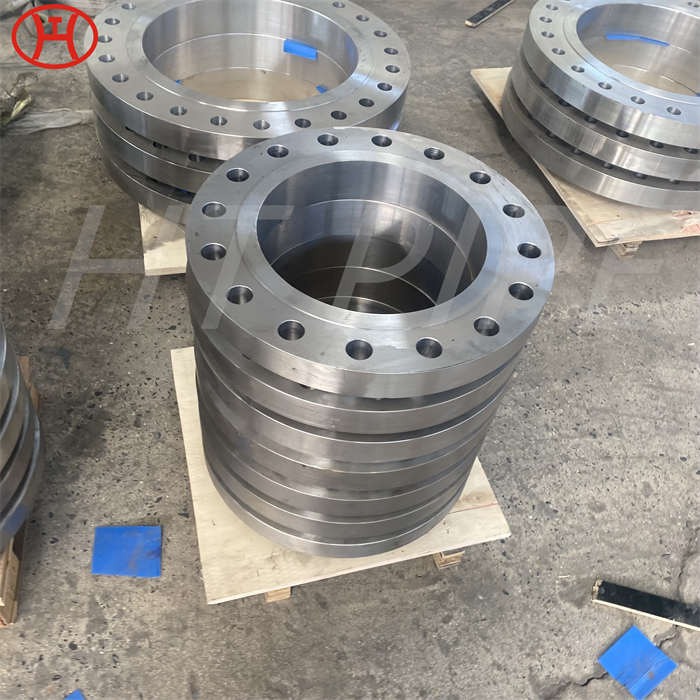

254 SMo / EN 1.4547 / UNS S31254 / 6Mo super austenitic steel combines moderate tensile strength and high ductility with excellent corrosion resistance in seawater and variety of industrial environment. Typically the 254 SMo pipe has PREN of 42 – 44, which ensure that the resistance to pitting corrosion is high and 254 SMo pipe also has a hight resistance to crevice corrosion. Alloy 6MO tubing is a high-alloy austenitic stainless steel designed for maximum resistance to pitting and crevice corrosion. The high levels of chromium, molybdenum, and nitrogen make 254 SMO (6-moly) suitable for high chloride environments such as brackish water, seawater, pulp mill, bleach plants, and other high chloride process streams. Since EN 1.4547 pipe is compatible with the common austenitic stainless steels. UNS S31254 tube is often used as a replacement in critical components of larger constructions where type 316L or 317L has failed by pitting, crevice attack, or chloride stress corrosion cracking. Though alloy 6MO is substantially stronger than the common austenitic grades, 6Mo tube is also characterized by high ductility and impact strength.

With high levels of chromium, molybdenum, and nitrogen, 254SMO seamless pipe is especially suited for high chloride environments such as brackish water seawater pulp mill bleach plants and other high chloride process streams. 254SMO welded pipe offers chloride resistance superior to that of Alloy 904L, Alloy 20, Alloy 825 and Alloy G. 254SMO is compatible with the common austenitic stainless steels. Even at higher temperatures, 254SMO has a high gap in corrosion resistance in seawater, a property that only a few stainless steels have. Due to its stable austenitic structure, it is more susceptible to welding-related thermal cracking and should generally be welded with low heat input.

Chemical Requirements

Alloy 6MO (UNS S31254)

Composition %

|

C |

Mn |

P |

S |

Si |

Cr Chromium |

Ni Nickel |

Mo |

N |

Cu |

|

0.020 max |

1.00 max |

0.030 max |

0.015 max |

0.80 max |

19.5–20.5 |

17.5–18.5 |

6.0–6.5 |

0.18–0.22 |

0.50–1.00 |

Dimensional Tolerances

|

OD |

OD Tolerance |

Wall Tolerance |

|

≤ .500″ |

± .005” |

± 15% |

|

.500″–.750″ |

± .005” |

± 10% |

Mechanical Properties

|

Yield Strength: |

45 ksi min |

|

Tensile Strength: |

98 ksi min |

|

Elongation (min 2″): |

35% |

|

Hardness (Rockwell B Scale): |

96 HRB max |