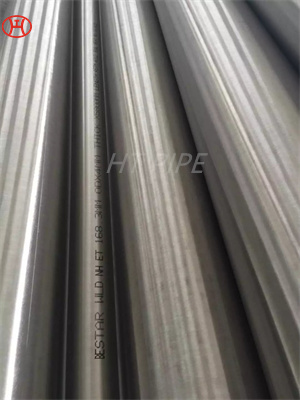

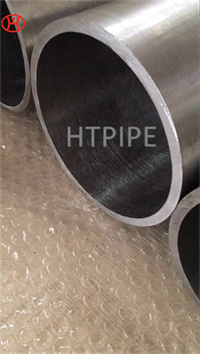

Stainless steel pipes of 254smo X1CrNiMoCuN20-18-7

Since 254S MO stainless steel pipe is a high alloy material, the manufacturing process is quite complicated. Generally speaking, people can only rely on traditional processes to manufacture this special stainless steel pipe, such as seamless, casting, forging, rolling, etc.

254 SMo / EN 1.4547 / UNS S31254 / 6Mo Piping

254 SMO contains high amounts of these elements and is suitable for demanding environments such as chlorinated seawater. Especially with the increase of nickel and molybdenum content, the resistance to stress corrosion cracking increases. UNS S31254 pipe is made of an austenitic stainless steel designed for maximum resistance to pitting and crevice corrosion. With high levels of chromium, molybdenum, and nitrogen, EN 1.4547 tube is especially suited for high chloride environments such as brackish water seawater pulp mill bleach plants and other high chloride process streams. UNS S31254 pipe offers chloride resistance superior to that of Alloy 904L, Alloy 20, Alloy 825 and Alloy G. 6Mo Piping is compatible with the common austenitic stainless steels.

254 SMO seamless tube is often used as a replacement in critical components of larger constructions where Type 316L or 317L has failed by pitting, crevice attack, or chloride stress corrosion cracking. In new construction, alloy 254SMO has been found in many cases to be a technically adequate and much less costly substitute for nickelbased alloys and titanium. 6Mo pipe is substantially stronger than the common austenitic grades, but is also characterized by high ductility and impact strength. EN 1.4547 pipe is readily fabricated and welded. In addition, EN 1.4547 welded pipe has a high molybdenum content and a higher oxidation rate during annealing, and stainless steel with a rough surface after pickling is more common than ordinary stainless steel. However, there is no adverse effect on the corrosion resistance of this steel.

UNS S31254 is a high-alloy austenitic stainless steel developed for use in seawater and other aggressive chloride-bearing media. The 1.4547 is characterized by the following properties:

- Excellent resistance to pitting and crevice corrosion, PRE = ≥42.5*

- High resistance to general corrosion

- High resistance to stress corrosion cracking

- Higher strength than conventional austenitic stainless steels

- Good weldability

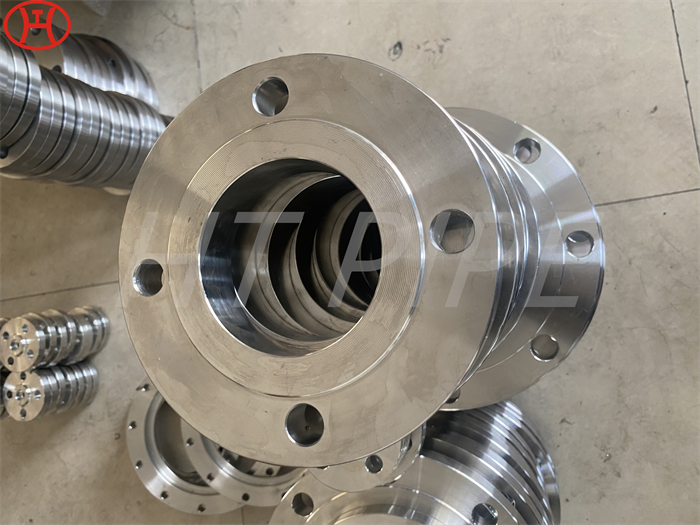

ASME/ASTM Specifications Of 254 Smo Seamless Pipe

| Specifications | Astm A312/ ASME SA312,Astm A213/ ASME SA213 |

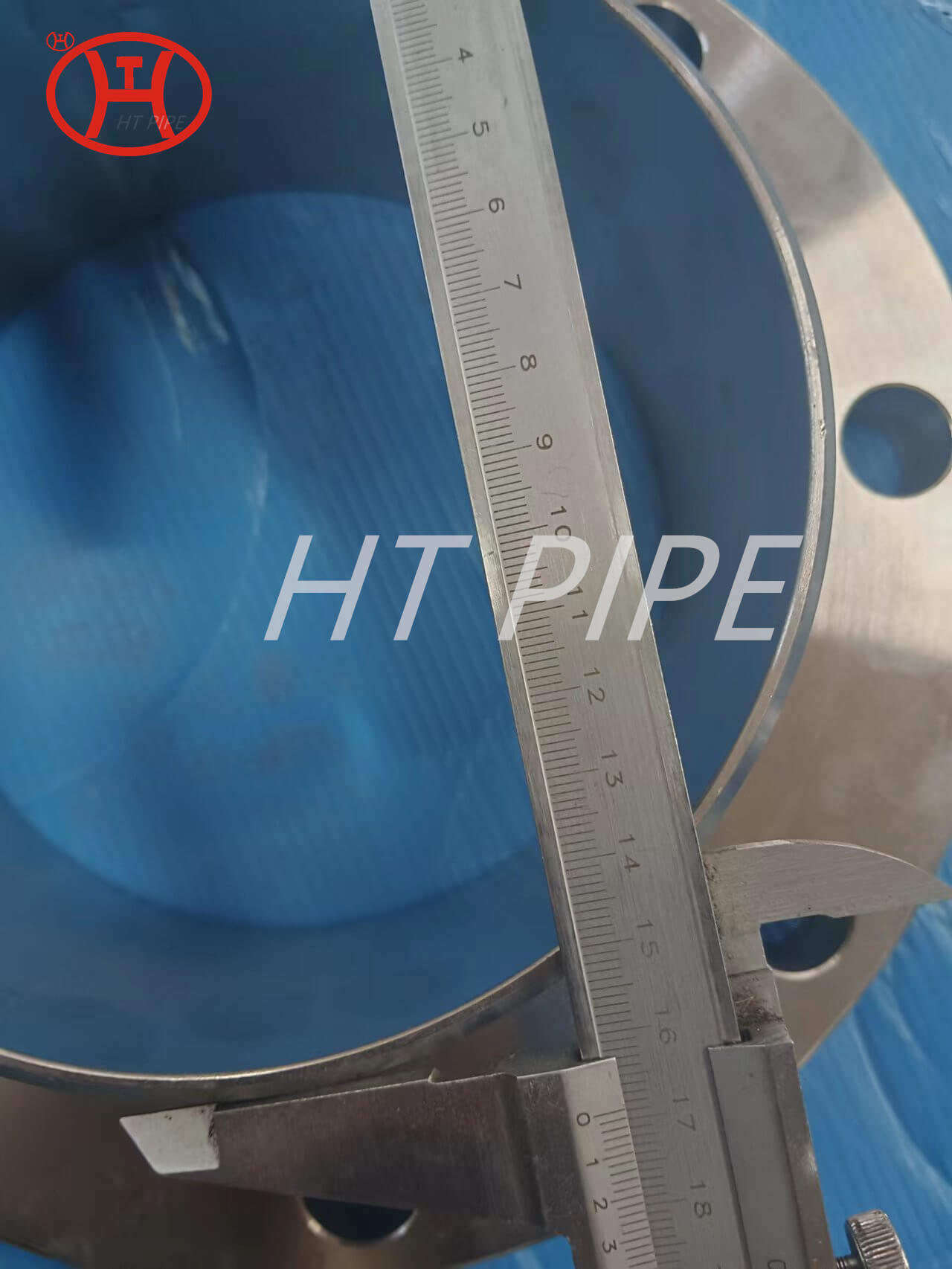

| Pipe Thickness | 0.3mm – 50 mm |

| Pipe Standard | EN, ASTM, ASME AISI, GB, JIS, DIN 254 SMO Pipe Supplier |

| 254 SMO Seamless Pipe Outer Diameter | Sizes up to 12” NB/ 6.00 – 250 mm OD |

| 254 SMO Welded Pipe size | 5.0 to 1219.2 mm |

| 254 SMO Welded Tube Size | 6.35 – 152 mm OD |

| 254 SMO EFW Pipe size | 5.0 – 1219.2 mm |

| 254 SMO tubing wall thickness | 0.0020″ to 0.0220″ (custom wall thicknesses available) |

| 254 SMO Seamless Tube Size | 15 NB – 150 NB IN/ 3.35 To 101.6 mm OD, |

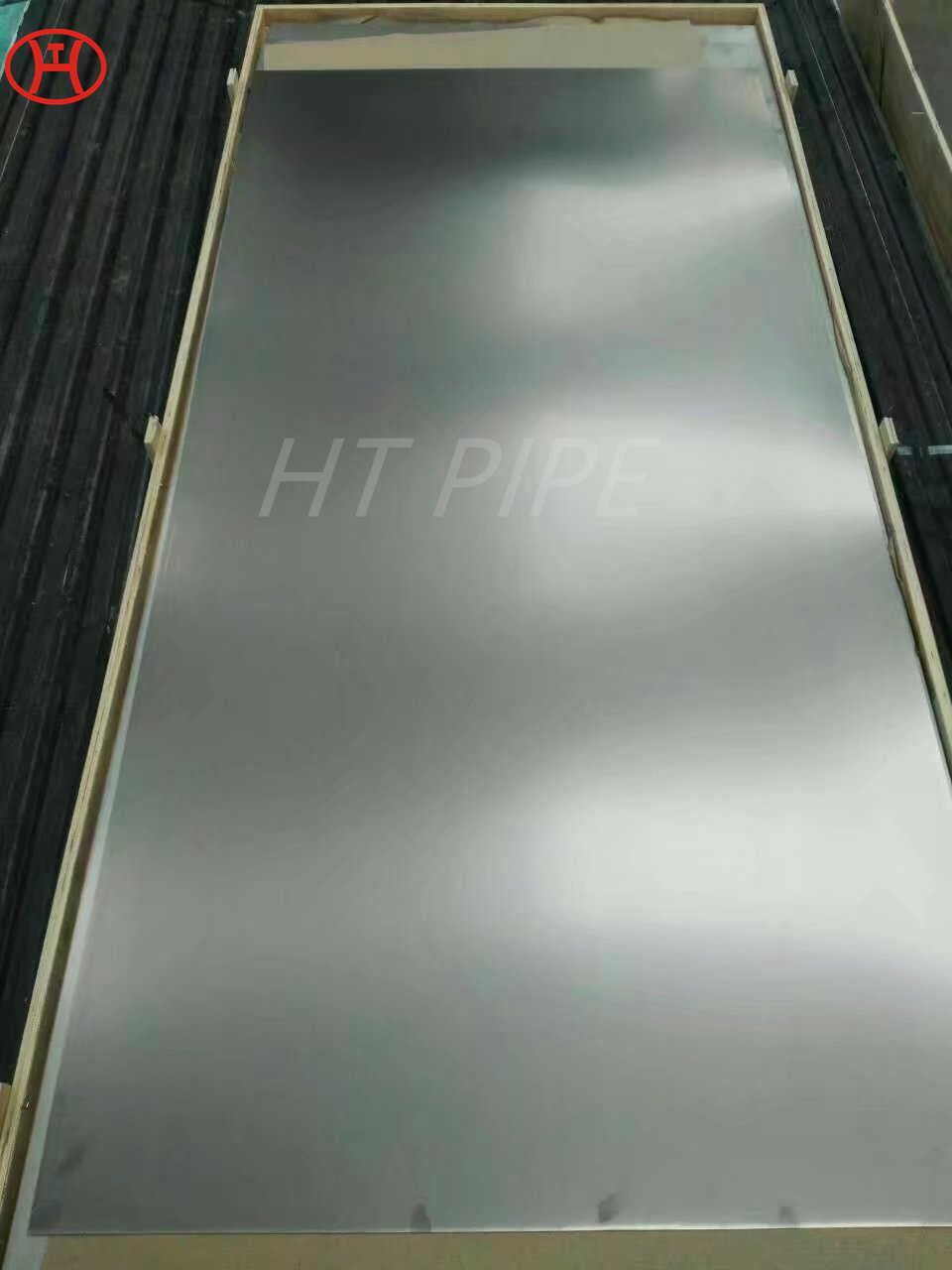

| 254 SMO Pipe & Tube Finish | AP (Annealed & Pickled), Polished, MF, BA (Bright & Annealed), NO.4, NO.1, BA, 2B, 8K, HL, Mirror finish,etc |

| Pipe & Tube Swg & Bwg | 12 Swg., 10 Swg., 16 Swg., 14 Swg., 20 Swg, 18 Swg. |

| 254 SMO Pipe Schedule | SCH10, SCH 5, SCH 80, SCH 40, , SCH 160, SCH 80S, SCH XS, SCH XXS |

| 254 SMO Pipe & Tube Form | Hydraulic, Round, Rectangular, Hollow, Pan Cake Coils, Square, Coiled, “U” Shape, Straight Pipes etc. |

| 254 SMO Pipe & Tube Length | Standard & Cut length, Single and Double Random, |

| 254 SMO Pipe & Tube Type | 254 SMO ERW/ Seamless / Welded / EFW / CDW /Fabricated / CEW/ DOM Pipe |

| Pipe Value Added Service | as per required Size & Length Draw & Expansion , Pickled Bending and Polish (Electro & Commercial) Annealed, Machining Etc. |

| 254 SMO Tube Application | Oil Tube, Boiler and Heatexchanger, Gas Tube, Fluid Tube |

| 254 SMO Pipe & Tube End | Beveled End, Plain End, Treaded Pipe. |

| Pipe Marking | marked as follows All 254 SMO Pipes : Standard, Grade, Thickness, OD, Heat No. (Or according to the customer’s request.), Length |

| Material Test Certificates (MTC) | 100% Radiography Test Report, Raw Materials Certificate |

| Material Test Certificates (MTC) as per EN 10204 3.1, EN 10204/3.1B and EN 10204 3.2 | |

| Manufacturer Test Certificate | |

| Form A for Generalized System of Preferences (GSP) | |

| Fumigation Certificates | |

| Third Party Inspection Report | |

| Heat Treatment Charts | |

| 254 SMO Tubes HS Code Commercial Invoice | |

| Laboratory Test Certificate from Govt. Approved Lab. | |

| Manufacturer | ASTM B165 254 SMO Seamless Pipe make Seah Steel Corporation, Korea |

| 254 SMO Pipe make Nippon Steel Corporation, Japan | |

| ASTM B165 254 SMO Pipe make Kobe Special Tube, Japan | |

| 254 SMO Pipe make Sanyo Special Steel, Japan | |

| 254 SMO Pipe make Tubacex Tubos Inoxidables S.A., Spain | |

| 254 SMO Pipe make Sumitomo Metals, Japan | |

| ASTM B165 254 SMO Pipe make Schoeller Bleckmann, Austria | |

| Specialized in | 254 SMO Heat Exchanger & Condenser Tubes |

| 254 SMO Capillary Tube & Other Odd Size | |

| Large Diameter 254 SMO Pipe |