A312 S31254 1.4547 Stainless steel pipes

The high molybdenum content of 254SMO stainless steel makes it have a higher oxidation rate when annealed, resulting in a rougher surface after pickling than ordinary stainless steel. However, this has no adverse effect on the corrosion resistance of the steel.

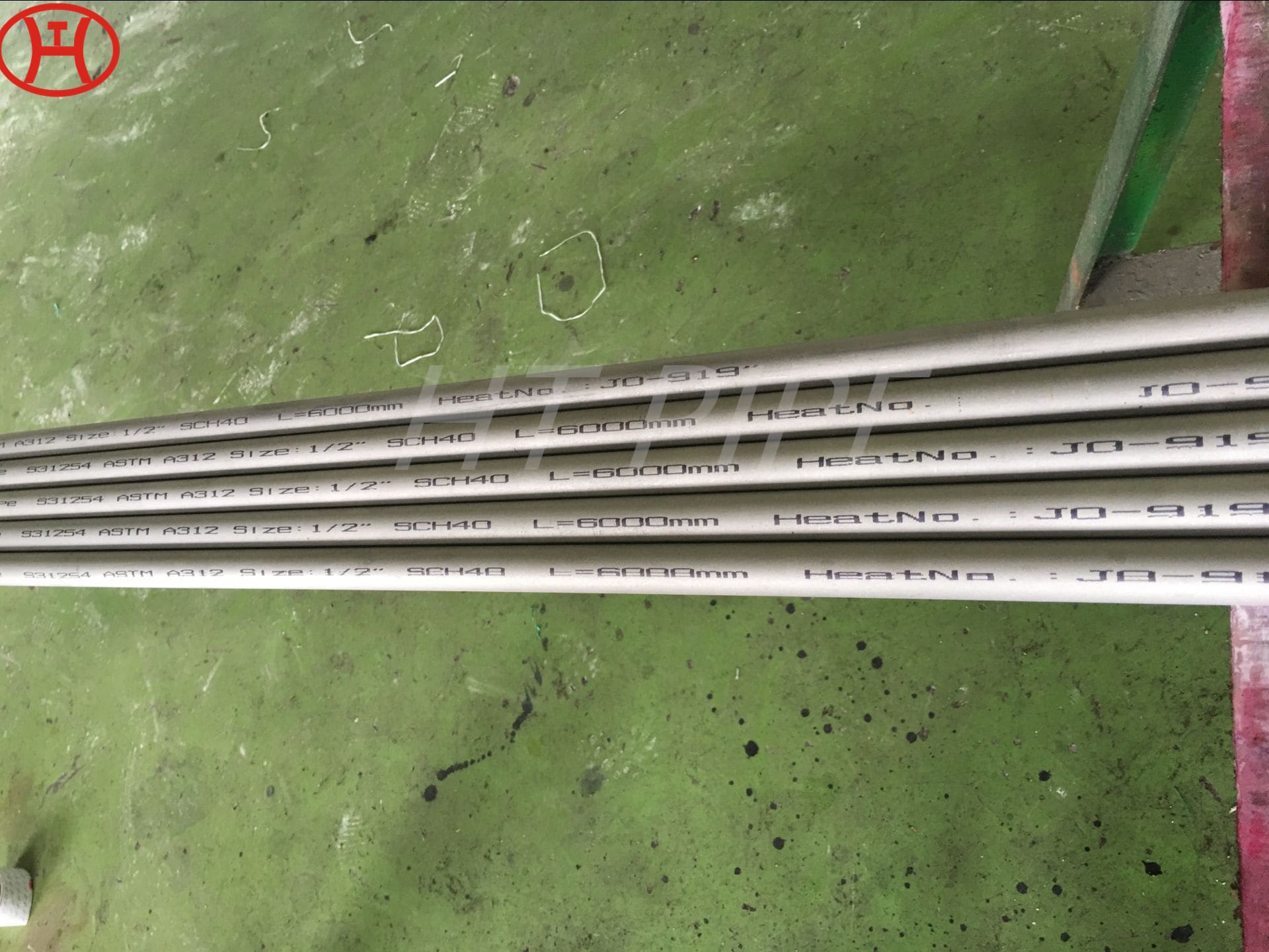

254 SMO Pipe Stockist, SMO 254 Seamless Pipe UNS S31254, ASTM A269 Alloy 254 Seamless Pipe Material, 254 SMO Flex Pipe Stockholder, 254 SMO Pipe Price, ASTM A312 Alloy 254 Polished Pipes Supplier

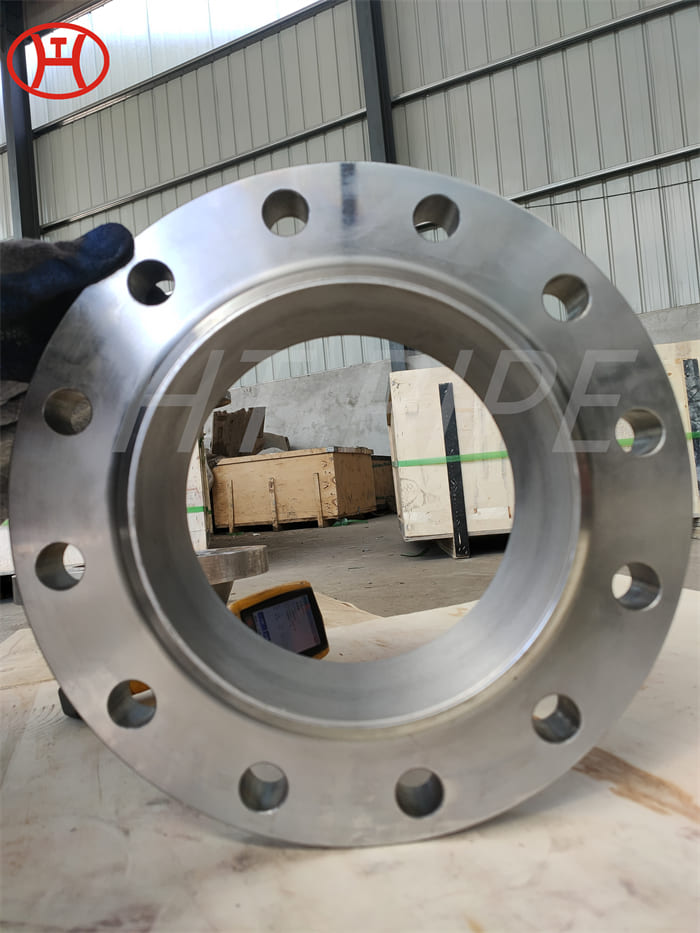

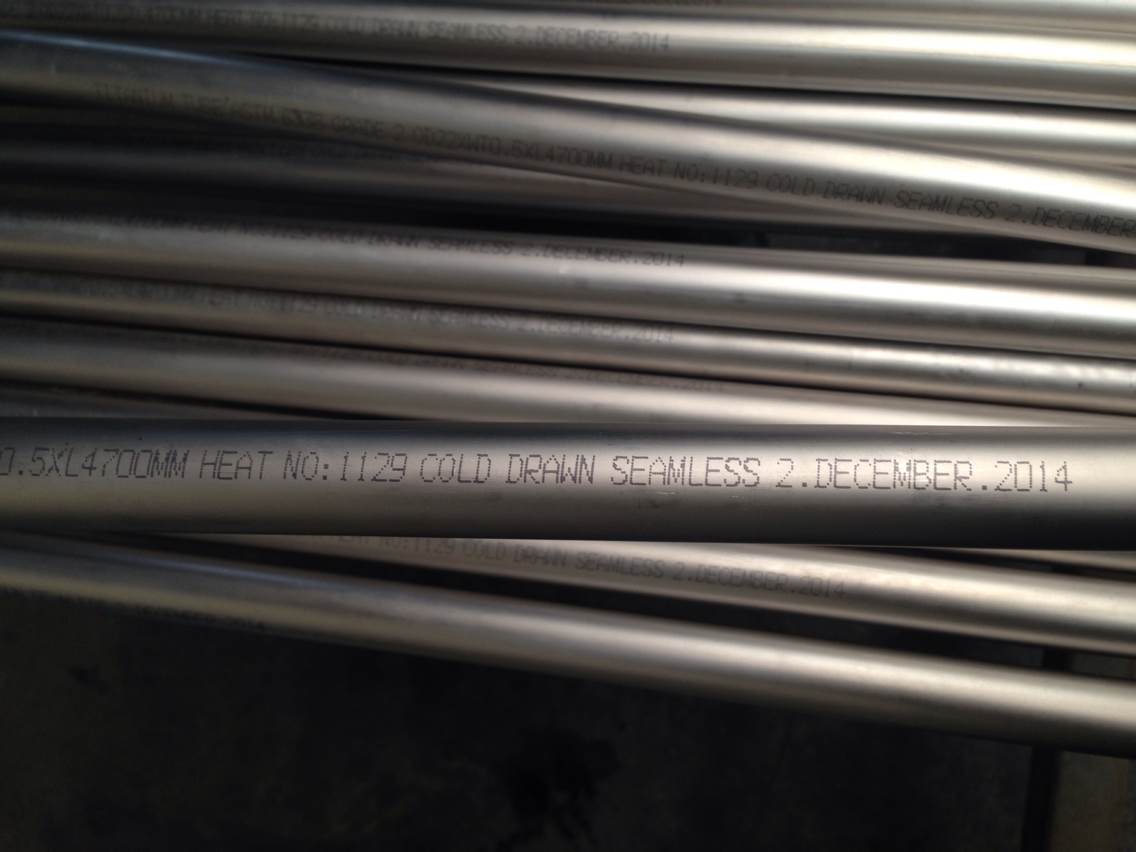

SMO 254 Seamless Tubes are used in the industries for having the perfect flow of fluids from one place to another. 1.4547 pipe is often used in the gas cleaning industries with the best flow that is there with the desalination. The 1.4547 pipes and tubes are available in many forms like square, rectangular, electro polish, hexagonal, and different others. ASTM A312 UNS S31254 pipe is used in the warm chloride environments with the pitting and corrosion resistance environments.

With the presence of the stainless steel alloying elements, the SMO 254 Seamless Pipes are having different properties. Some of the properties which are there with ASTM A269 Alloy 254 Seamless Pipe are corrosion resistance, great ductility, durability, high tensile strength, great yielding strength, stability in the elevated temperatures. The presence of the properties is the reason that the pipes and tubes are used in the industries for different applications. So, some of the industries which are using SMO 254 Welded tubes are petrochemical, pharmaceuticals, oil and gas, pulp and paper, railways, construction, offshore equipment, chemical equipment, and others. ASTM A269 1.4547 S31254 pipes are having the smooth flow of work with the help of the pipes and tubes.

254SMO is a face-centered cubic lattice structure. In order to obtain austenitic structure. In some cases, the material may carry traces of metallic interphases. However, their impact strength and corrosion resistance are not adversely affected under normal conditions. ASTM A312 1.4547 pipe is recommended that the temperature not exceed this range as it can cause fouling and reduce the machinability of the material. To regain maximum corrosion resistance, post-treatment annealing is recommended. Stainless grade 254 SMO does not respond to heat treatment. Hardening is only possible by cold rolling.

CHEMICAL COMPOSITION OF SMO 254 SEAMLESS PIPES AND TUBES

|

Grade

|

Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

| SMO 254 | 17.5 – 18.5 | 19.5 – 20.5 | 6 – 6.5 | 0.5 – 1 | 0.18 – 0.22 | 0.02 max | 1 max | 0.8 max | 0.03 max | 0.01 max |

MECHANICAL PROPERTIES OF SMO 254 WELDED PIPES AND TUBES

|

Grade

|

Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| SMO 254 | 650 | 300 | 35 |