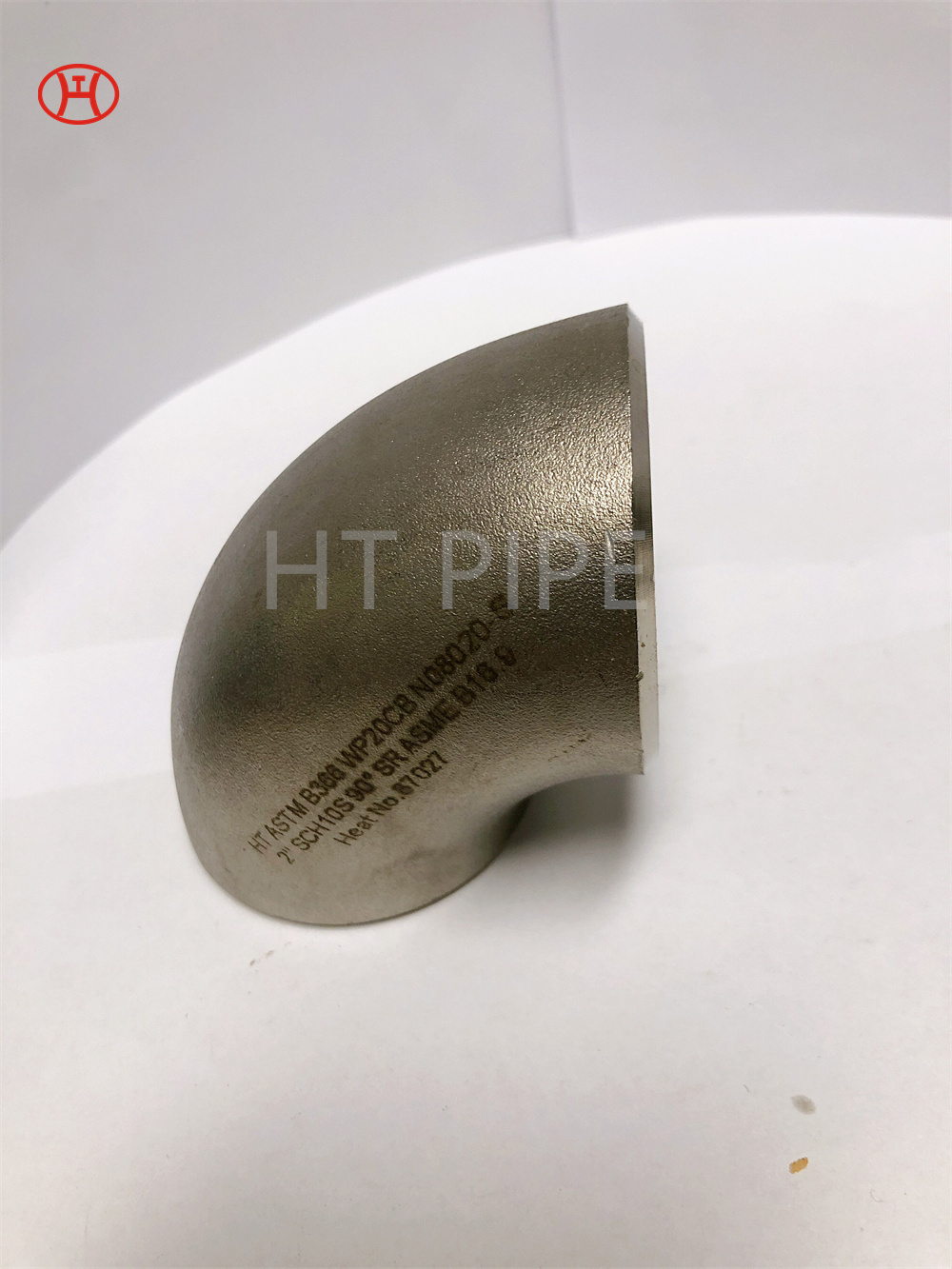

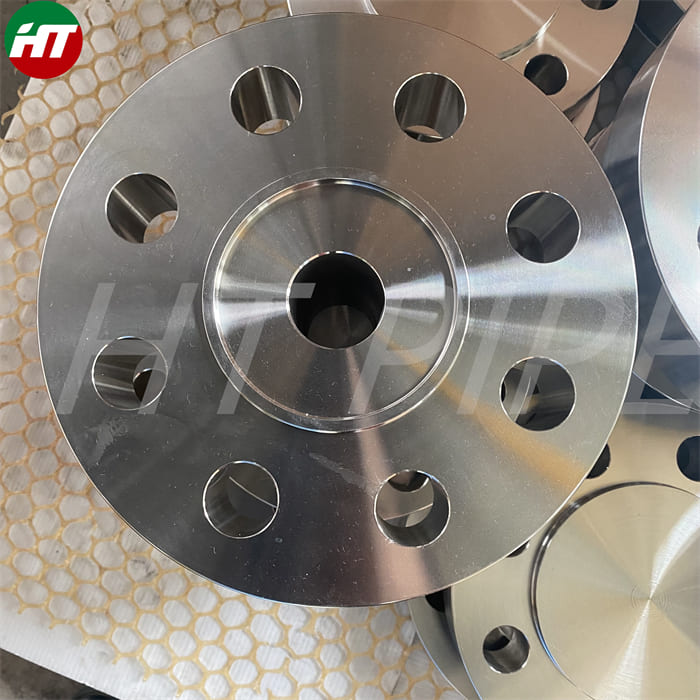

Stainless steel threaded en 10204 type 3.1 316 filter gasket elbow sus ss 304 flanges

Stainless Steel SS UNS S30400 Flange is a high corrosion resistant steel, it is an austenitic stainless steel with higher corrosion resistance than Type 316l or grades and Type 317l. Due to the addition of some elements, this material has excellent corrosion resistance to reducing acids such as sulfuric acid. It is used in plants and is widely used in a variety of different types of applications

ASTM A182 F304 Flange Chemical Composition And Mechanical Properties Of DIN 1.4301 SS 304 Flanges

Stainless steel 304 S30400 flanges are easy to weld and provide a strong welded connection in petrol and fresh water tanks. SS 304 flange comes in handy if temperature fluctuations are part of the production process. At the same time, SS 304 flanges are considered to be the most basic stainless steel, also known as grade 18-8, with higher chromium content and lower carbon content. The presence of low carbon content in the alloy limits the formation of carbide deposits during welding while minimizing the susceptibility of 304 1.4301 stainless steel flanges to intergranular corrosion. This composition makes the SS 304 flange strong and corrosion resistant for general corrosion service.

Regarded to be the most basic stainless steel, the SS 304 flange are also known as 18-8 grade with a higher content of chromium and low carbon content. The presence of low carbon content in the alloy restricts the formation of carbide precipitates during welding along with minimizing the 304 Stainless Flanges from being susceptible to intergranular corrosion. The high chromium content in the alloy provides the ASME B16.9 Sa 182 Gr F304 BLRF Flanges with resistance to oxidizing solutions such as nitric acid up to 55% weight and up to a temperature of 176°F. Flanges made from alloy 304 is also known to resists moderately aggressive organic acids like acetic acid. The nickel present in the alloy is what provides resistance to the ASTM A182 Gr F304 Flange in moderately reducing solutions for e.g. in pure phosphoric acid, whatever the concentration, in cold solutions as well as up to 10% diluted hot solutions.

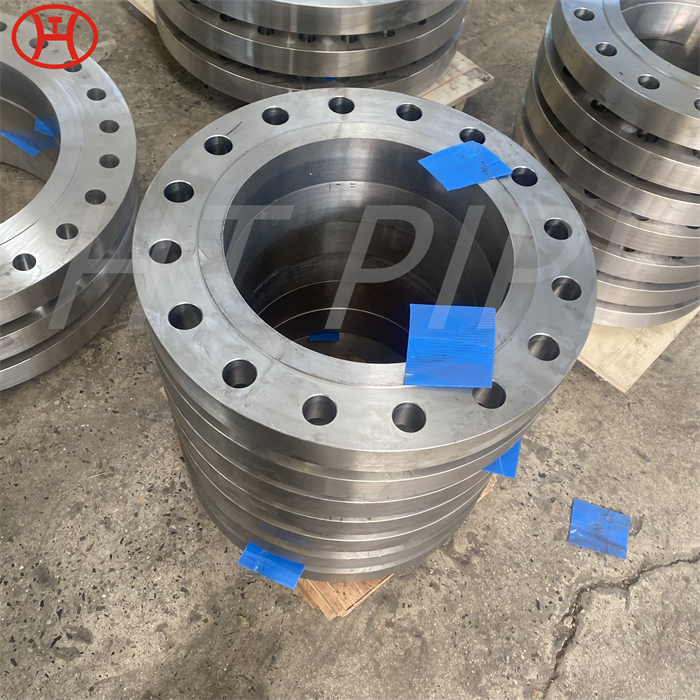

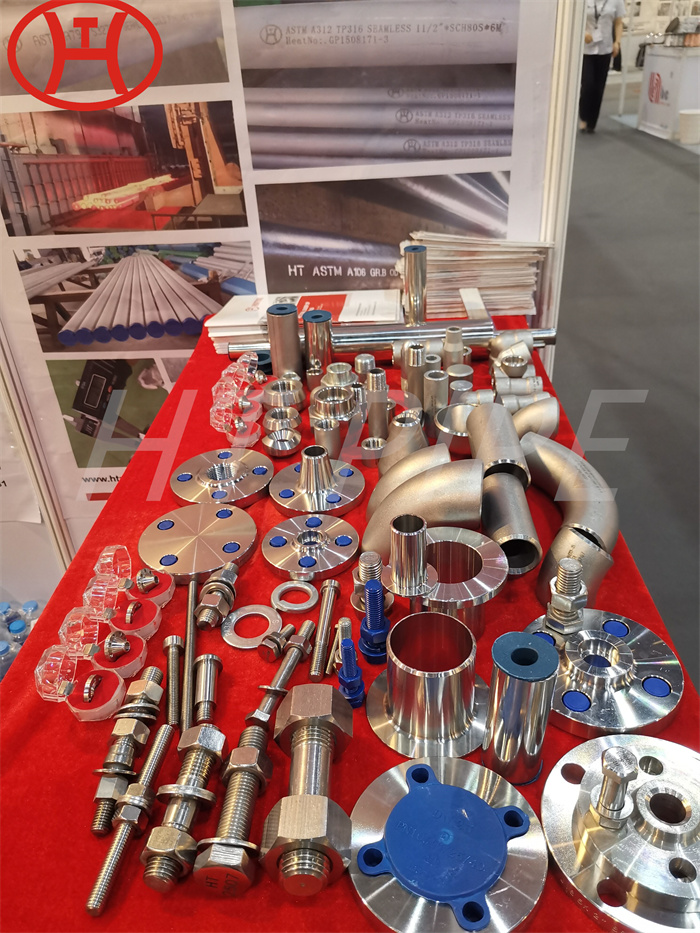

Type: WN/LWN/SO/SW/blind/plate/threaded/anchor/swivel/girth/lap joint/reducing/orifice

spectacle blind/paddle blind/spacer ring/orifice plate/bleed ring

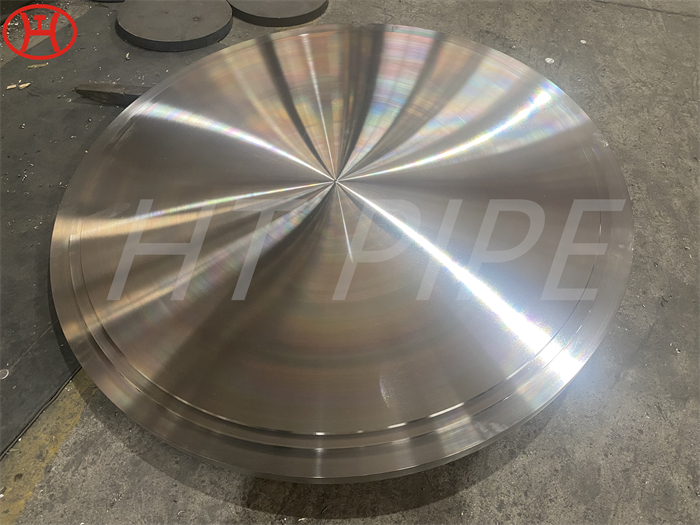

Speical Products: Rings/Forgings/Disc/Shaft Sleeve

Standard Type Class Size

ASME B16.5 WN/LWN/SO/Blind/Lap Joint 150#-2500# 1/2″-24″(Except Blind Flange 2500lb 1/2″-12″)

SW flange 150#-1500# 1/2″-3″(Except 1500# 1/2″-2 1/2″)

Threaded 150#-900# 1/2″-24″

1500# 2500# 1/2″-2 1/2″

ASME B16.47 Series A WN/blind flange 150# -900# 22″-48″(Except 900# Size:26″-48″)

ASME B16.47 Series B WN/blind flange 75#-300# 26″-48″

400# 600# 900# 26″-36″

DIN2527 Blind flange PN6-PN100 DN10-DN1000

DIN2543 SO flange PN16 DN10-DN1000

DIN2544 SO flange PN25 DN10-DN1000

DIN2545 SO flange PN40 DN10-DN500

DIN2565 Threaded flange with Neck PN6 DN6-DN200

DIN2566 Threaded flange with Neck PN16 DN6-DN150

DIN2567 Threaded flange with Neck PN25 PN40 DN6-DN150

DIN2568 Threaded flange with Neck PN64 DN10-DN150

DIN2569 Threaded flange with Neck PN100 DN10-DN150

EN1092-1:2002 Plate flange for welding/loose plate flange with weld-on plate collar or for lapped pipe end/Blind Flange/WN flange PN2.5-PN100 DN10-DN4000

JIS B2220 Welding Flange, Lap joint flange, threaded flange PN6-PN100 DN10-DN1500

BS4504 BS10 TableD/E Plate Flange for welding/WN flange/Blank Flange PN6-PN100 DN10-DN1500

Sealing Surface RF FF RTJ TF GF LF LM

Flange Face Finish Stock Finish/Spiral Serrated/Concentric Serrated/Smooth Finish(Ra 3.2 and 6.3 micrometers)

125-250 AARH(it is called smooth finish)

250-500 AARH(it is called stock finish)

Coating Vanish, yellow paint, anti-rust oil, galvanizing etc

Stainless Steel ASTM A182 ASTM A182 F304/F304L

ASTM A182 F316/F316L/F316Ti

ASTM A182 F316MoLN/F316LN

ASTM A182 F310/F317L/F347

ASTM A182 F51/F53/F55/F44/F904L/F60/F95