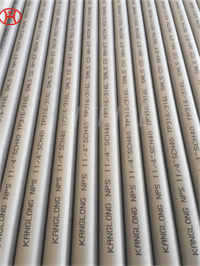

Stainless Steel Tube Thin Wall Seamless 70mm

We stock an extensive inventory of high-quality standard and special grade of seamless stainless steel tube and welded stainless steel tubing.

Product description:

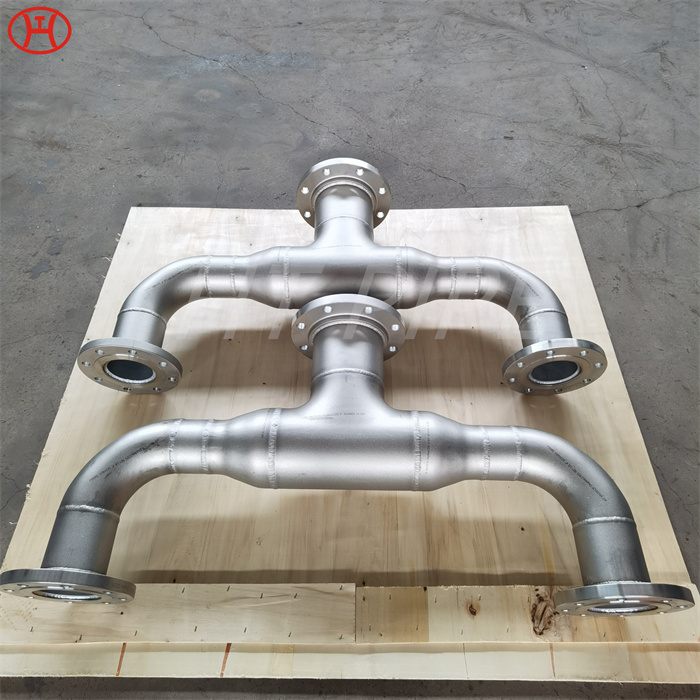

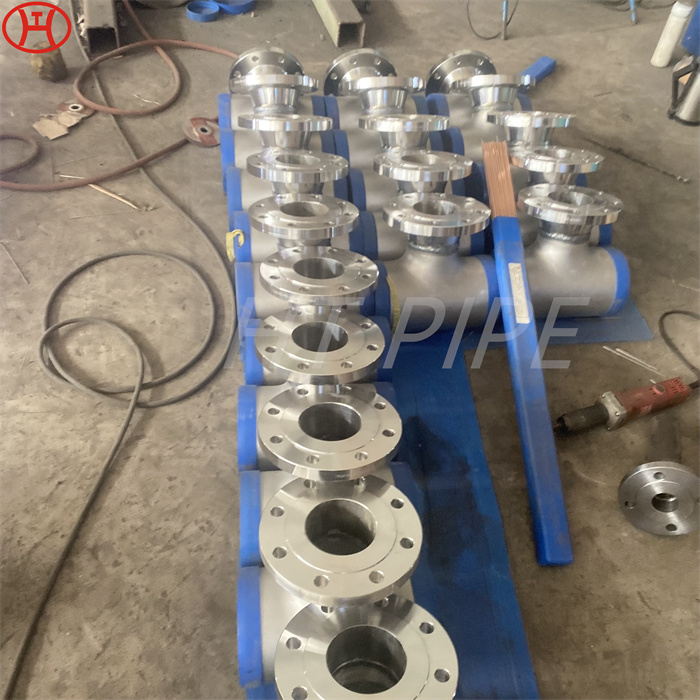

Stainless steel pipes are typically specified for the OD (outside diameter) and WT (wall thickness) and mechanical properties of the base stainless steel material. It is resistant to many forms of corrosion, has hygienic sterile properties, high-quality aesthetic appeal and exceptional strength. Stainless steel round pipes are also commonly used for their resistance to corrosion and contamination, as well as their ability to withstand high pressures. Materials were stored in annealed and pickled, bright annealed, ground and polished conditions.

Stainless steel and nickel-based alloy tubes also have excellent heat resistance and low-temperature performance, and have been used as raw materials in harsh environments such as petroleum refining processes, petrochemical and power generation sectors. Recently, they have been used in construction applications due to their high aesthetic quality It is widely used in new demand fields such as semiconductor and liquid crystal manufacturing equipment applications that require high cleanliness.

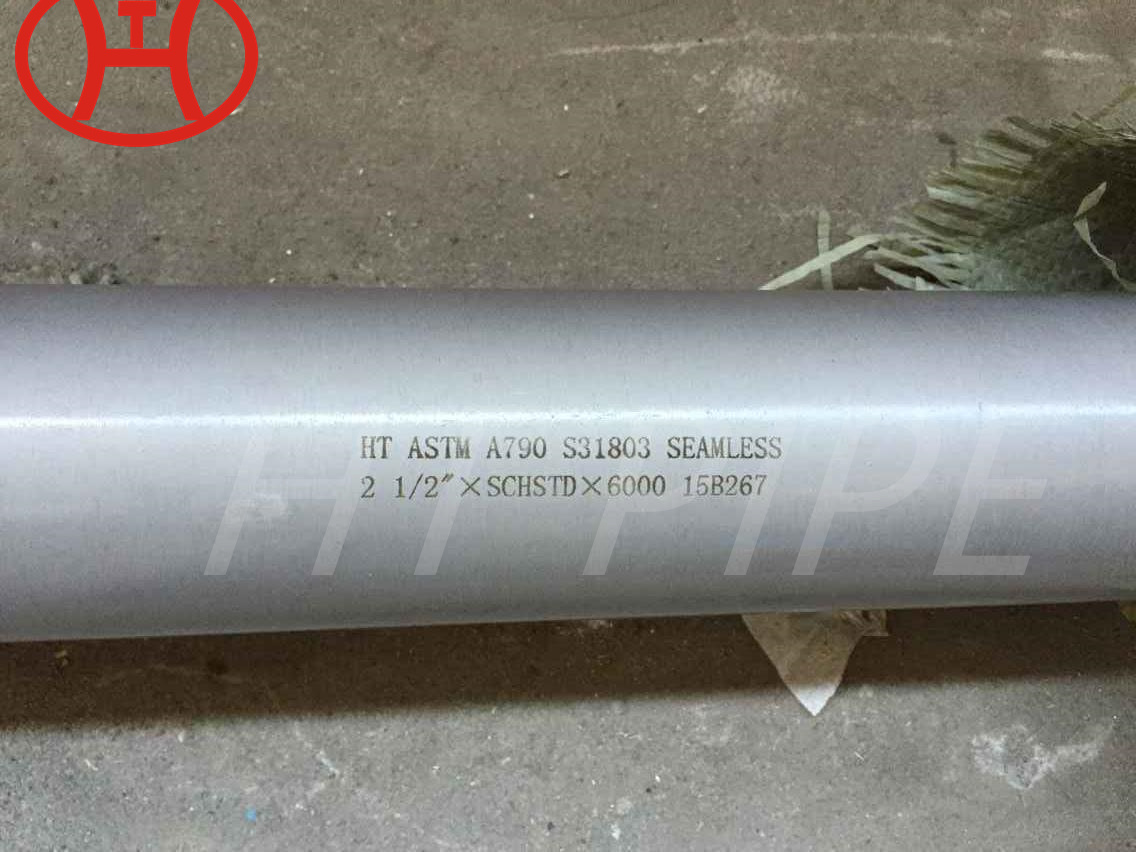

Our stainless steel and nickel-based alloy pipes are manufactured based on excellent technology and strict quality control from raw materials to final products, and have won a good reputation in various fields. Our 300 series has increased strength and corrosion resistance for applications in harsh environments and meets the requirements of your stainless steel pipe projects. ASTM standard specifications include A213 seamless pipe, A269 welded pipe, A511 seamless mechanical pipe and A554 decorative pipe with annealed and pickled and bright annealed fabrication options.

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1/2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling /Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Stainless Steel ASTM A312 TP304,TP304L,TP316,TP316L,316Ti TP317,TP317L,TP321,TP310S,TP347,S31254,NO8367,NO8926,NO8904

ASTM A213 TP304,TP304L,TP316,TP316L,316Ti TP317,TP317L,TP321,TP310S,TP347,S31254,NO8367,NO8926,NO8904

ASTM A269 TP304,TP304L,TP316,TP316L,TP317,TP317L,TP321,TP347,S31254,NO8367,NO8926

ASTM B676 N08367

ASTM B677 UNS N08925, UNS N08953