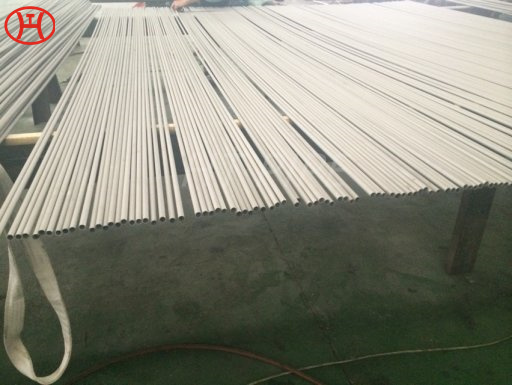

ASTM A160 Steel Pipe SA106 seamless carbon steel pipe

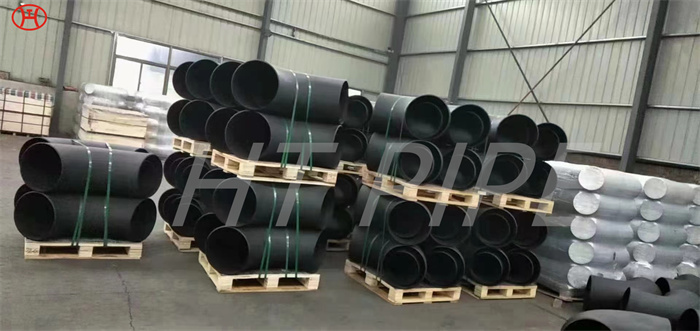

ASTM A106 seamless pressure pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers, and ships where the piping must transport fluids and gases that exhibit higher temperatures and pressure levels.

ASTM/ ASME A106/SA106 Seamless Carbon Steel Pipe

ASTM SA/A106 pipe (also covered in ASME specifications as SA/A106) is the standard specification for seamless carbon steel pipe for high-temperature service. Most common uses are in refineries and plants when gasses or fluids are transported at high temperatures and pressures.

A106 pipe is American standard material, including A, B, C three grades, the ingredients of A106 A is carbon and silicon, the tensile strength grade is 330 MPa. The ingredients of A106 B is carbon、manganese and silicon, the tensile strength grade is 415 MPa. The ingredients of A106 C is carbon, manganese and silicon components, the tensile strength grade is 485 MPa.

ASTM A106 seamless pressure pipes (also known as ASME SA106 pipes) are commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers and ships. These pipes must carry fluids that exhibit higher temperature and pressure levels And gas.

ASTM standards are divided into the following six types.

1. Standard Test Method: It is a prescribed procedure used to identify, test and uate the quality, characteristics and parameters of materials, products, systems or services.

2. Standard Specification: It puts forward technical requirements and specific instructions for materials, products, systems, or projects, and also proposes procedures that should be adopted to meet the technical requirements.

3. Standard Practice: It is a program that explains one or more specific operations or functions, but does not produce test results.

4. Standard Terminology: It describes or defines nouns, and explains symbols, abbreviations, and acronyms.

5. Standard Guide: It selects a series or explains its usage, but does not introduce specific implementation methods.

6. Class Fication: It distinguishes and classifies materials, products, systems, or specific services according to their source, composition, performance or use.

ASTM SA/A106 Mechanical Properties

| Properties | Grade B | Grade C | |

|---|---|---|---|

| Tensile Strength, min., psi, (MPa) | 60,000 (415) | 70,000 (485) | |

| Yield Strength, min., psi, (MPa) | 35,000 (240) | 40,000 (275) | |

ASTM SA/A106 Chemical Properties

| Grade | C, max. | Mn | P, max. | S, max. | Si, min. | Cr, max. | Cu, max. | Mo, max. | Ni, max. | V, max. |

|---|---|---|---|---|---|---|---|---|---|---|

| Grade B | 0.30 | 0.29 – 1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| Grade C | 0.35 | 0.28 – 1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |