Stockholders of ASTM A312 Alloy 254 Polished Pipes 254 SMO High Alloy Stainless Steel Pipes

Stainless steel grade 254 SMO Pipe is a very high end austenitic stainless steel.

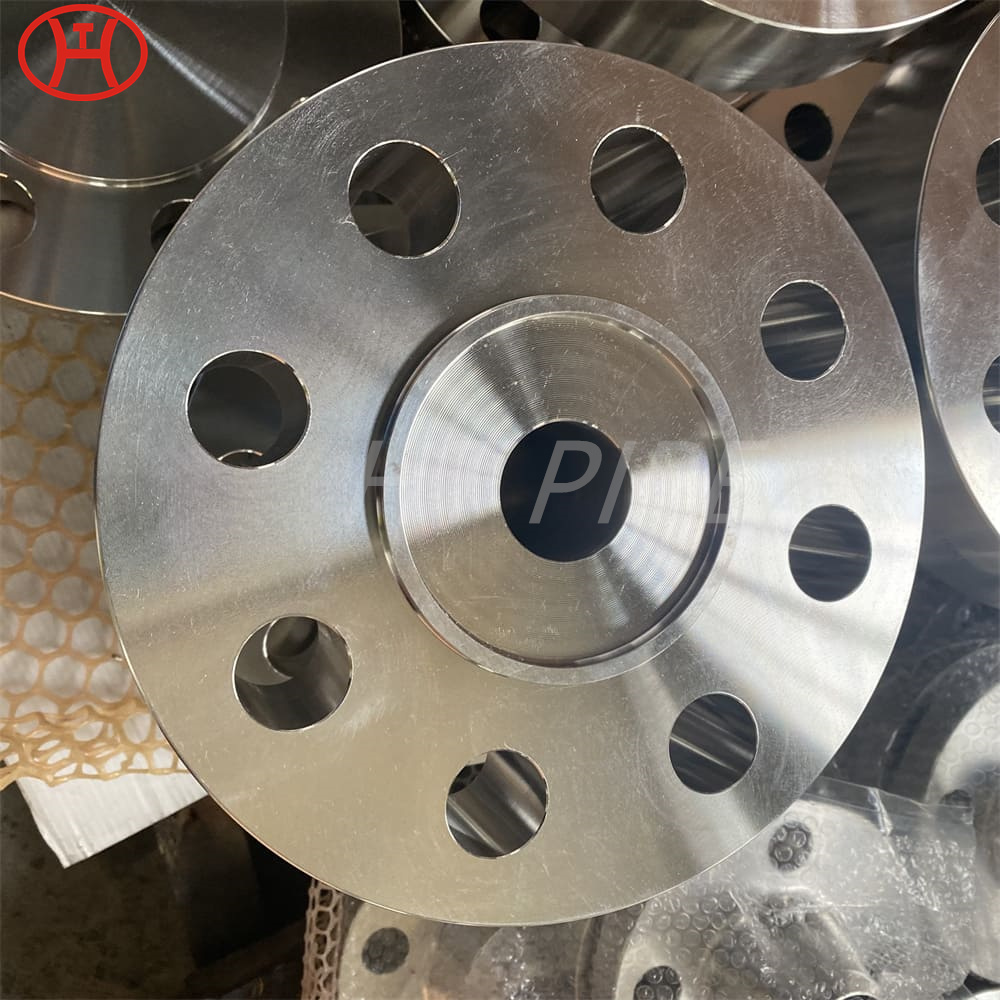

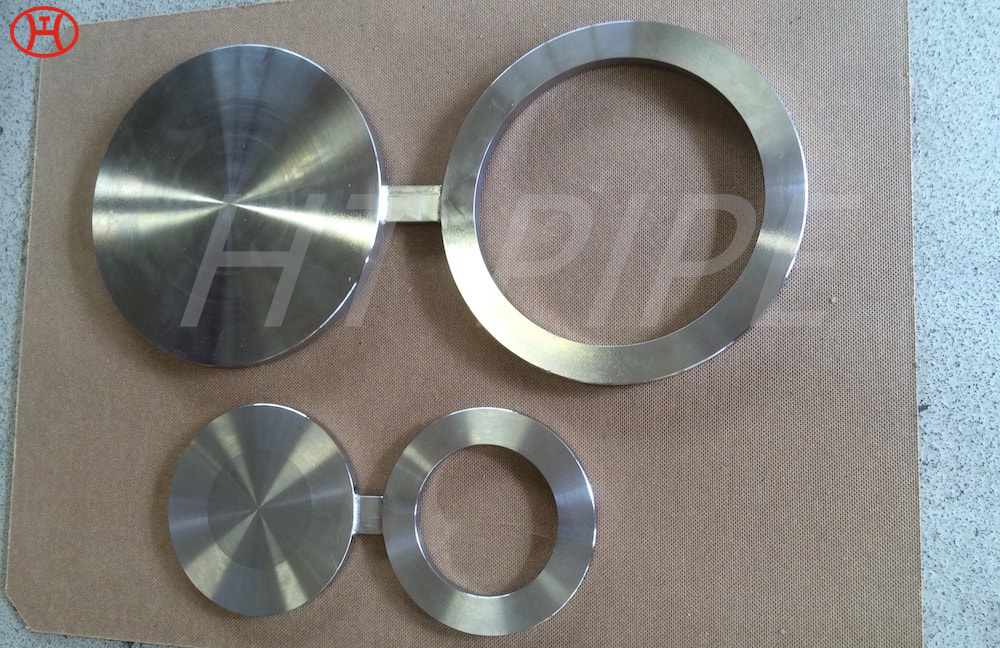

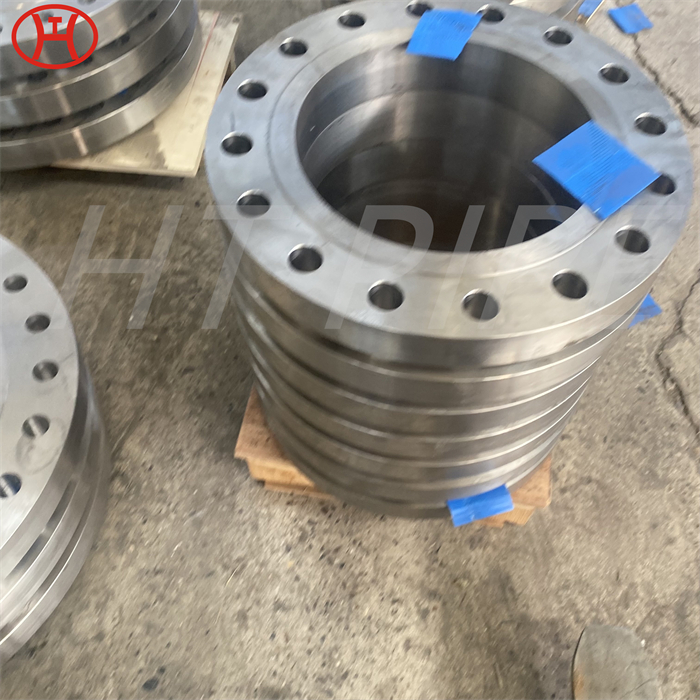

254 SMO ERW Pipe, Stainless Steel 254 SMO Welded Pipe, SS 254 SMO Seamless Pipe, ASME SA 312 254 SMO SS Pipes, Stainless Steel Alloy 254 SMO Pipe Stockists, Alloy 254 Pipes, 254 SMO EFW Pipes Exporter in China.

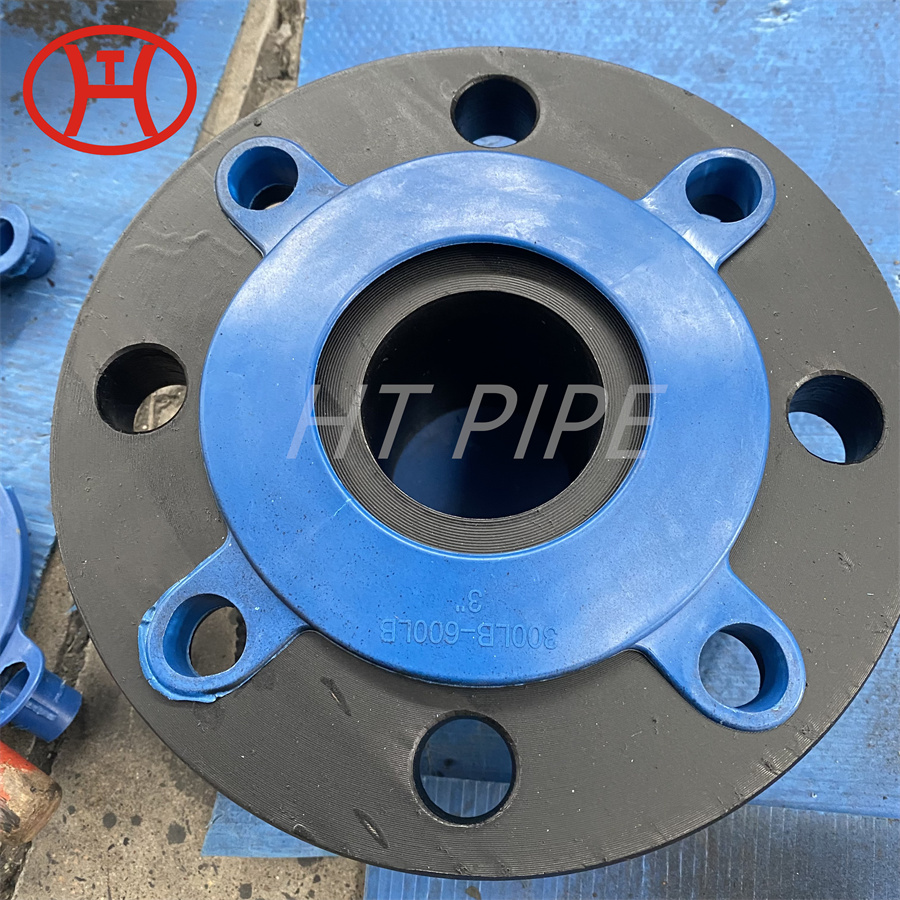

UNS S31254 Welded Pipe is designated as UNS S31254 and Werkstoff Number 1.4547. 254 SMO Seamless pipe standard is ASTM A312, A269, A213, EN 10216-5, NFA 49-217, and 254 SMO Stainless Steel Pipe, Stainless Steel 6Mo Pipe: ASTM A249, A269, A312, A358, A409. The UNS S31254 Welded Pipes are manufactured according to international and national quality standards. The 254 SMO E254 SMO ERW Pipes are available in various grade, thickness, and specifications as per the request of buyers and at good rates. The entire manufacturing process held under the tight supervision of professional experts that are having skills of product development so that the high quality of Stainless Steel 254 SMO Welded Pipe development can be guaranteed. We are mandatorily developing the SS 254 SS 254 SMO Seamless Pipe in such a way that ASASME SA 312 254 SMO SS Pipe could assure national and international product quality standards. We, 254 SMO EFW Pipes Exporter in China, also consider the production norms for the development of 254 SMO Seamless Pipes.

Alloy 254 SMO is an austenitic stainless steel with a high molybdenum content. Coupled with Nickel and Copper this gives the UNS S31254 a good resistance to pitting and crevice corrosion, especially in environments containing halide ions, e.g. chloride, bromide and fluoride solutions. Stainless Steel 254 SMO Welded Pipe may offer a cost effective solution to Nickel and Titanium alloys in these environments. SMO DINSMO DIN NR. 1.4547 Pipe is generally known for its ideal use in the shipping sector in contact with seawater as well as in saline and sulphurous environments. ASASTM A269 Alloy 254 Seamless Pipe was developed for use in seawater and other aggressive chloride-containing media, up to food industry applications, and belongs to the super-austenite group. The increased molybdenum content and the addition of nitrogen provide excellent resistance to pitting and crevice corrosion.

Chemical Composition of 254 SMO Pipes

| Grade | Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

| SMO 254 | 17.5 – 18.5 | 19.5 – 20.5 | 6 – 6.5 | 0.5 – 1 | 0.18 – 0.22 | 0.02 max | 1 max | 0.8 max | 0.03 max | 0.01 max |

Mechanical Properties of SMO 254 / S31254 / 1.4547 Pipes

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 650 | 300 | 35% |