Super Austenitic Stainless Steel 904L UNS N08904 plate

904L stainless steel combines molybdenum and copper with iron for tremendously increased resistance to reducing acids like sulphuric acid. It stands up extremely well to chlorides in the environment for low pitting and crevice corrosion, as well as stress corrosion cracking.

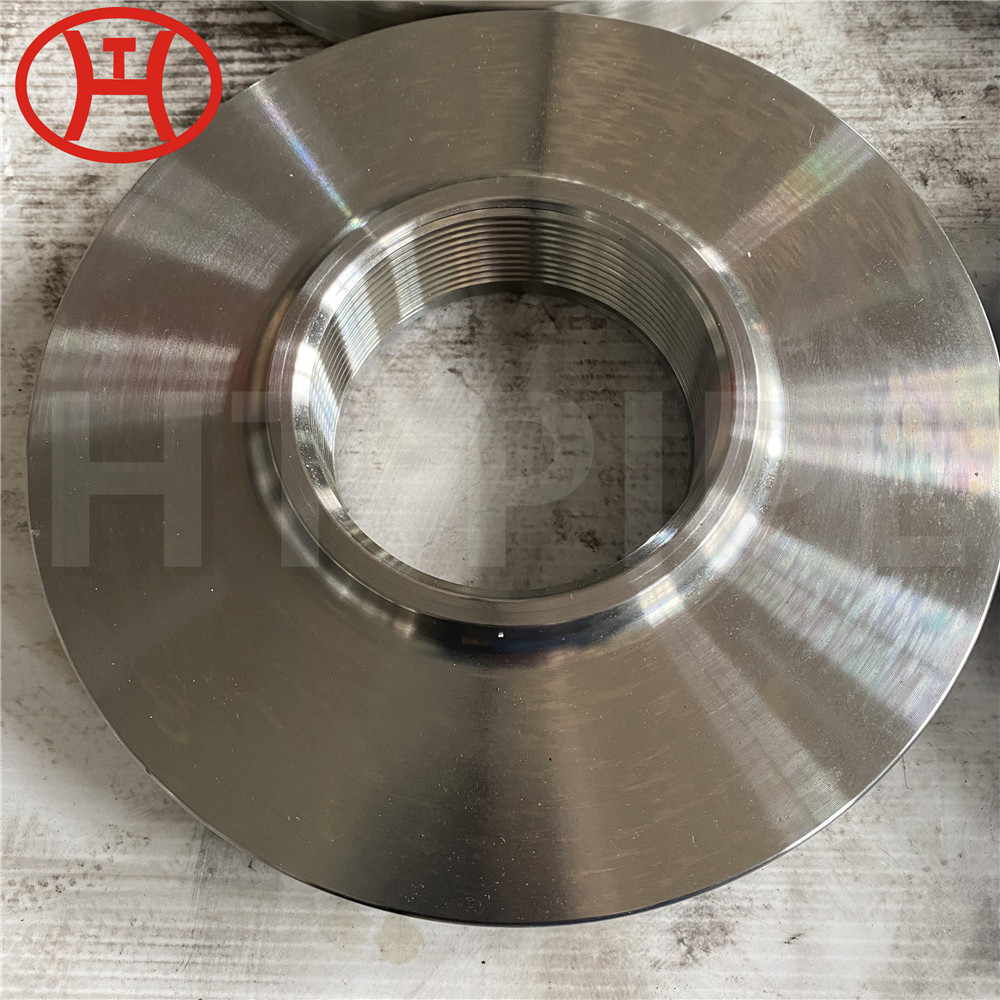

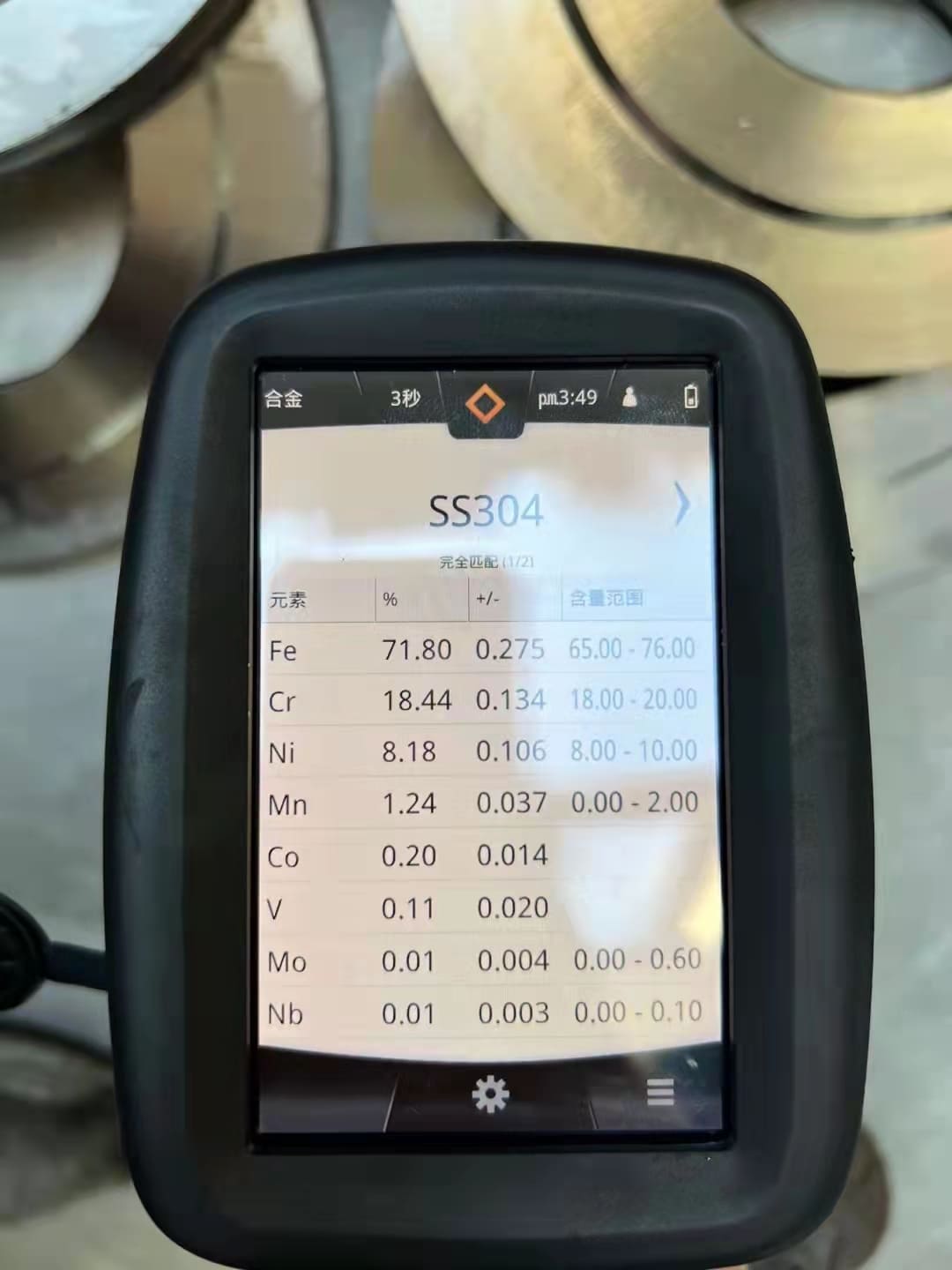

904l stainless steel plate consists of nickel, chromium, molybdenum, copper and manganese with nickel content ranging from 23% to 28%. 904l stainless steel sheet is a super austenitic stainless steel with low carbon content, designed for moderate to highly corrosive environments. DIN 1.4539 stainless steel plate has copper added to improve its resistance to strong reducing acids such as sulfuric acid. ASTM A240 UNS N08904 stainless steel plate is also resistant to stress corrosion cracking and crevice corrosion.

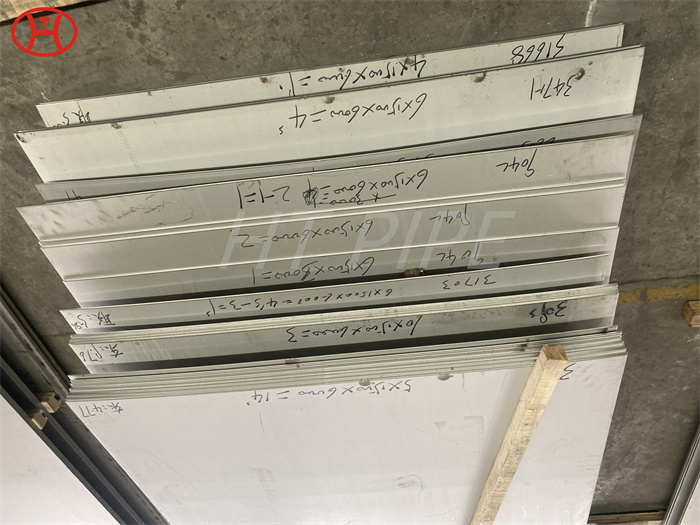

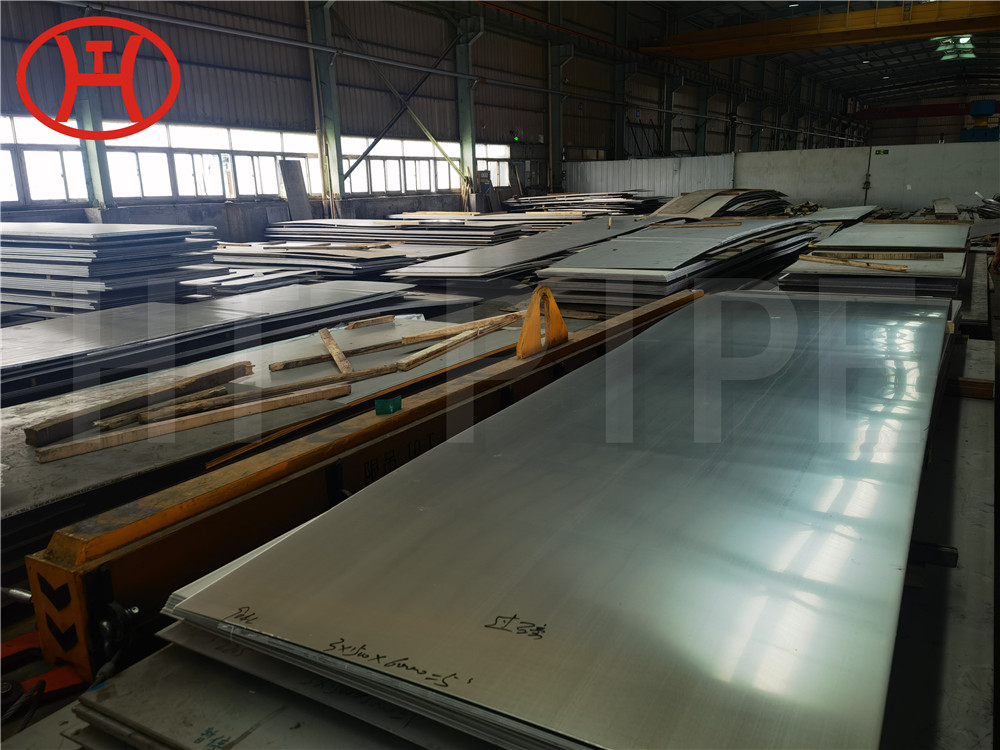

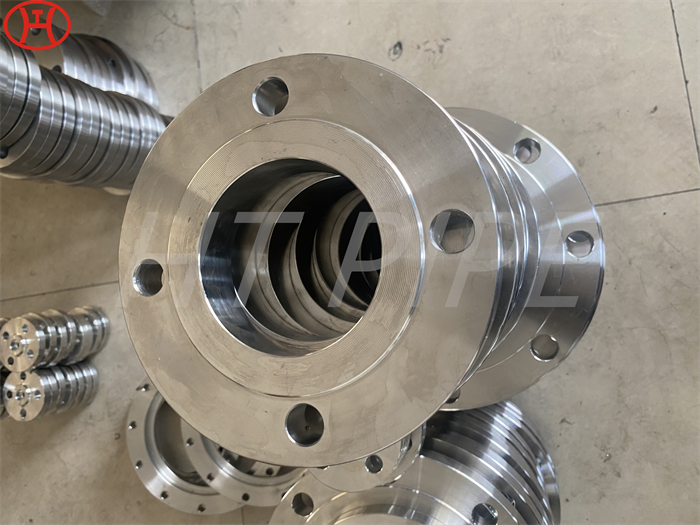

Sheets made from SS 904l material are generally available in a variety of sizes, thicknesses and finishes to suit specific application requirements. Stainless steel 904l plates are commonly used in the construction of storage tanks, vessels and piping systems exposed to highly corrosive environments, applications requiring high corrosion resistance, such as chemical processing plants, paper mills, and oil and gas industry equipment. 904l plates are also used in heat exchangers, air pollution control systems and seawater treatment equipment.

ASTM A240 904l Plate Mechanical & Physical Properties

| Element | SS 904L |

| Density | 7.95 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 71000 , MPa – 490 |

| Yield Strength (0.2%Offset) | Psi – 32000 , MPa – 220 |

| Elongation | 35% |

| Hardness | 70-90 typical |