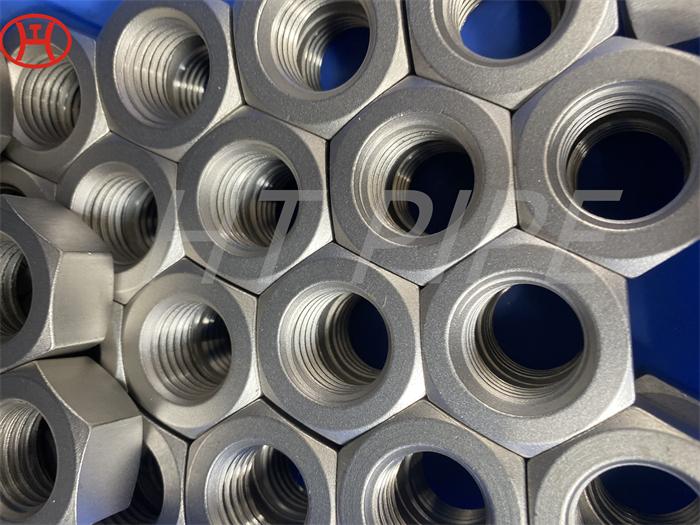

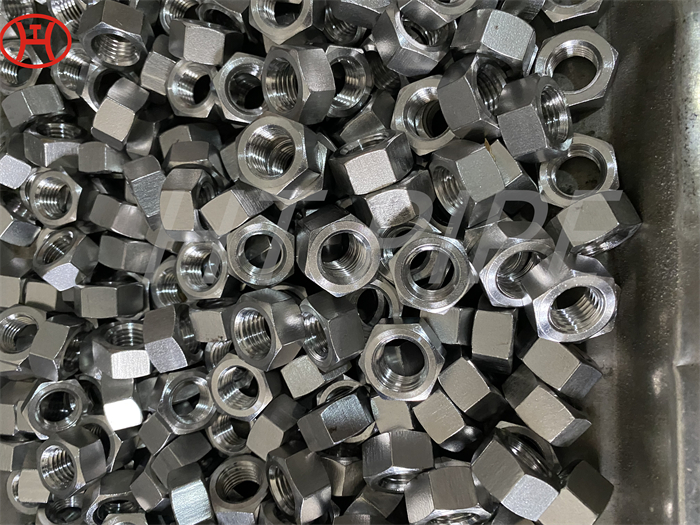

Super Duplex 2507 nut provides excellent resistance to pitting crevice and general corrosion

Due to the ferritic portion of the duplex structure of the alloy it is very resistant to stress corrosion cracking in warm chloride containing environments.

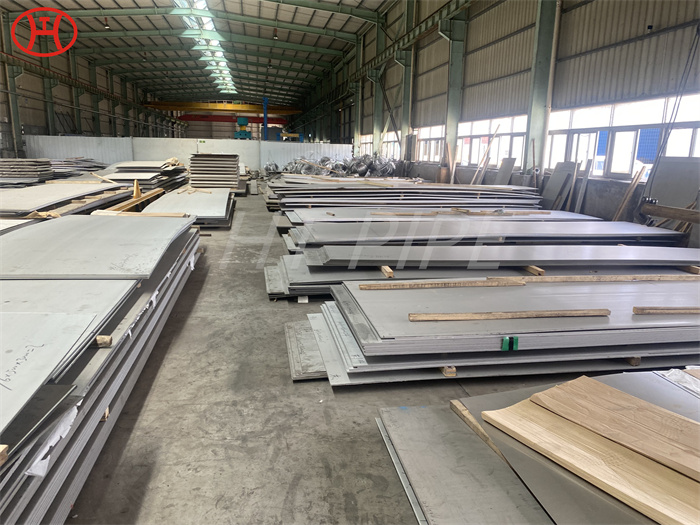

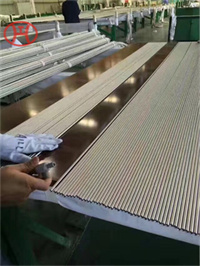

Alloy 2507 is a super duplex stainless steel with 25% chromium, 4% molybdenum and 7% nickel, designed for demanding applications that require exceptional durability and corrosion resistance, such as chemical and petrochemical processes and sea-water equipment. This type of steel is excellently resistant to shearing as a result of stress corrosion, high thermal conductivity and a low thermal expansion coefficient. The high chromium, molybdenum and nitrogen contents offer excellent resistance against pitting, crevice formation and general corrosion. Super Duplex 25 Chrome, or 2507, are cold hardened duplex stainless steels defined by having a Pitting Resistance Equivalent Number (PREN) greater than 40. Compared to 22 Chrome / 2205 Duplex, these alloys contain higher levels of chromium, molybdenum, and nitrogen, which increases their resistance to localized pitting and crevice corrosion.