Super Duplex 2507 Pipe Fittings ASTM A815 UNS S32750 Buttweld Tee

Super Duplex 2507 Equal tees are the most common fittings.

WERKSTOFF NR. 1.4410 Tee and ASME SA815 Pipe Fittings provide exceptional value when compared to other piping materials, S32750 fittings and 2507 pipe tee

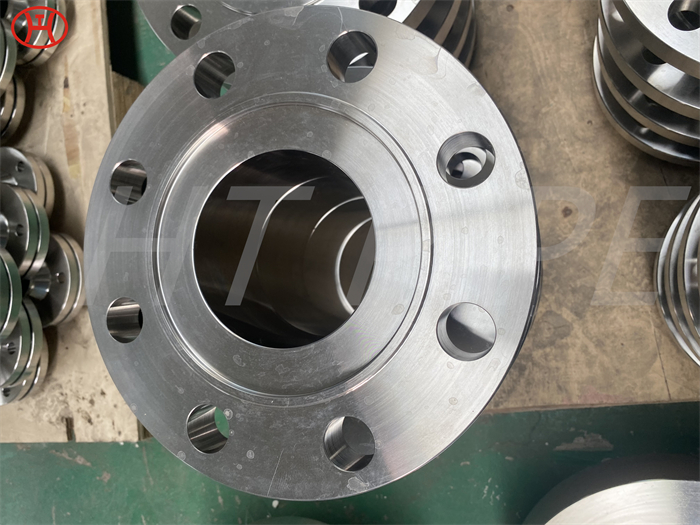

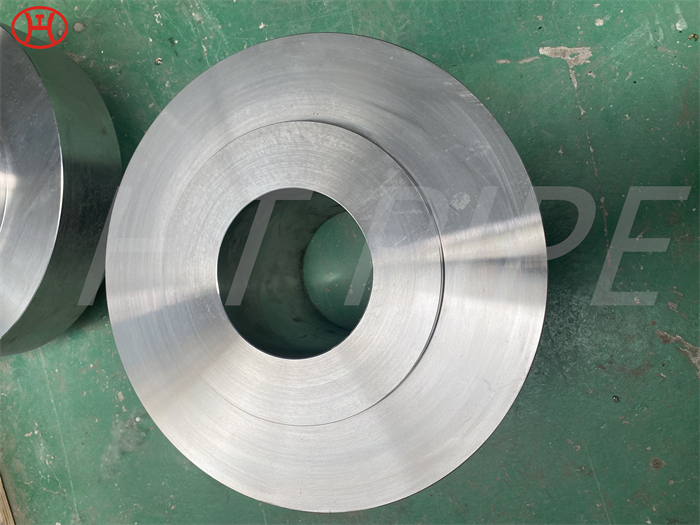

Super Duplex 2507 Tee or Tee connection in piping engineering is a very important pipe fitting and is frequently used to combine or divide a flow. Two types of ASTM A815 UNS S32750 Tee are available, Equal Tee and Reducing Tee. However, in pigged pipelines, one special type of Tee is widely used which is known as Barred Tee or Pigged Tee. HT PIPE offers a wide range of Super Duplex Steel S32750 / S32760 Tube similar to parker and swagelok to Union Fittings, which has some excellent features to offer such as lightweight, durable, dimensionally stable, and more. These Super Duplex Steel S32750 Compression Tube Fittings has excellent corrosion resistance to a wide variety of media, with outstanding resistance to pitting and crevice corrosion in seawater and other chloride containing environments due to its high chromium, molybdenum, and nitrogen level, with Critical Pitting Temperature exceeding 50 Degree C.

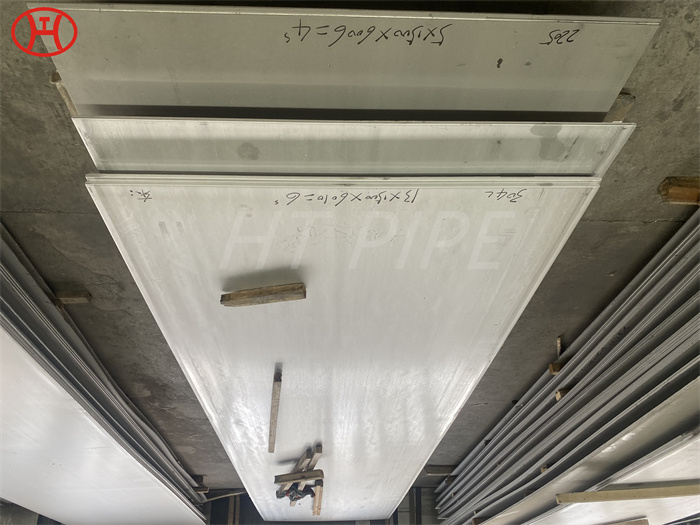

Our Super Duplex Steel S32760 Compression Tube Fittings is often used in Chemical Process Industry: such as in Nitric Acid Processes, Polypropylene Production, PVC Production, Dioxide, Caustic Evaporators, Equipment Handling Organic and Fatty Acids. Meanwhile, these Super Duplex S32750 Union Tube Fittings are also being offered in different sizes and shapes to our customers. However, due to the high mechanical strength values of our Super Duplex S32760 Union Tube Fittings, higher forming forces are required than for austenitic stainless steels. When performing cold forming, please note the high spring back properties of these Super Duplex S32750 Ferrule Fittings, which are also in addition suitable for hot forming. Our Super Duplex S32760 Double Ferrule Fittingss should be undertaken in the temperature range between 1000 Degree C and 1100 Degree C. After hot forming, rapid cooling is recommended in these ASME SA 815 Duplex Pipe Tees, and subsequent heat treatment may be required.

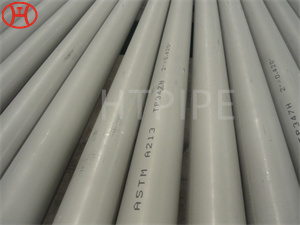

Stainless Steel Tube and Fittings

| Standard | Description |

| ASTM A213/A213M | Seamless ferritic and austenitic alloy steel boiler, superheater and heat exchanger tubes. |

| ASTM A249/A249M | Welded austenitic steel boiler, superheater, heat exchanger and condenser tubes. |

| ASTM A269 | Seamless and welded austenitic stainless steel tubing for general purposes. |

| ASTM A270 | Seamless and welded austenitic stainless steel sanitary tubing. |

| ASTM A450/A450M | General requirements for carbon, ferritic alloy and austenitic alloy steel tubes. |

| ASTM A554 | Welded stainless steel mechanical tubing. |

| ASTM A791/A791M | Welded unannealed ferritic stainless steel tubing. |

| ASTM A789/A789M | Seamless and welded ferritic/austenitic stainless steel tubing for general service. |

| AS1163 | Structural steel hollow sections (dimensional tolerances). |

| AS1528, Parts 1 to 4 | Tubes (stainless steel) and tube fittings for the food industry. |