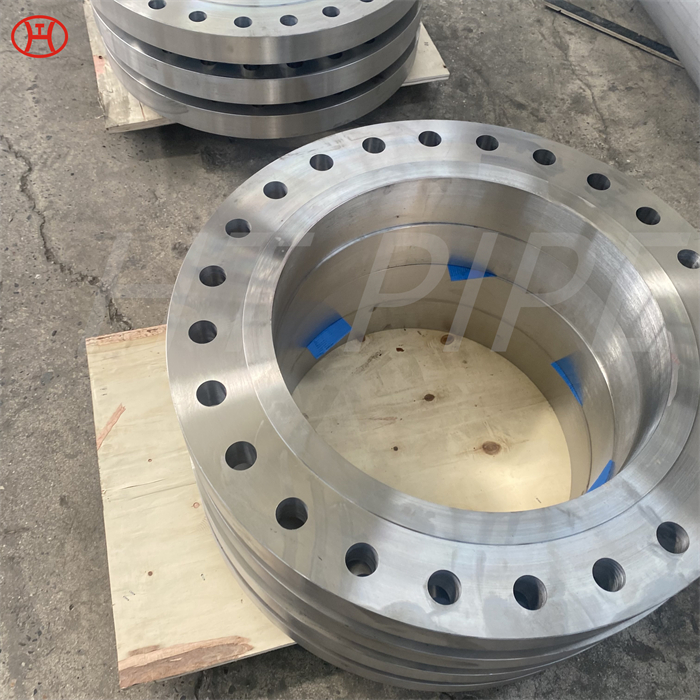

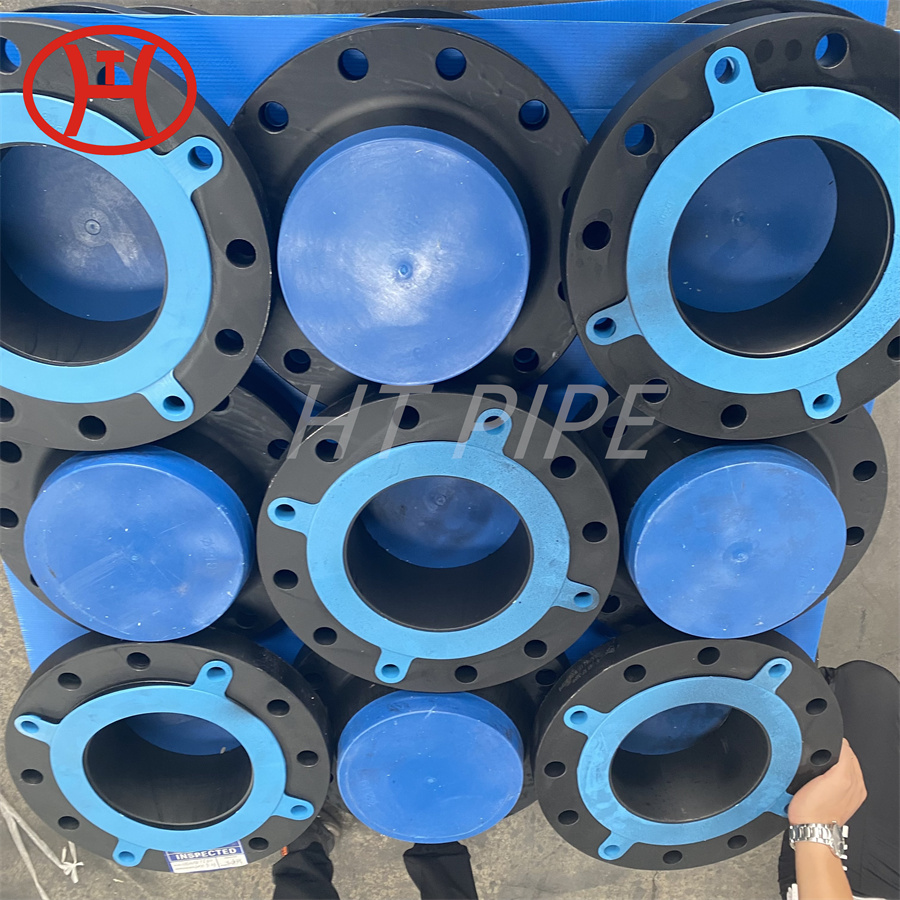

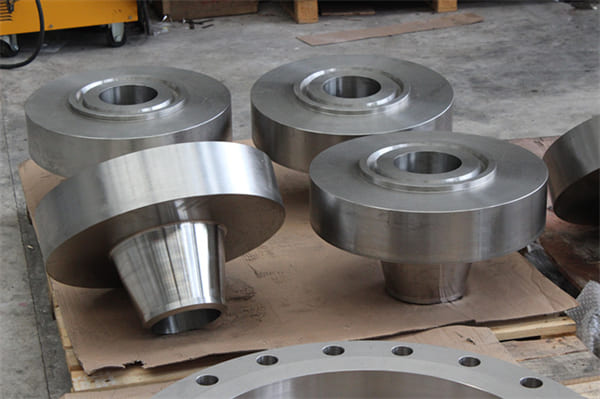

Super Duplex F53 Orifice WN BL SO SW Flange S32750 A182 Forged Flange

ANSI B16.5 Super Duplex Stainless Steel S32750 Orifice Flange provides excellent resistance to a wide range of corrosive environments, including seawater, acidic solutions, and chloride-containing environments. Super Duplex F53 WN Flange exhibits higher corrosion resistance than standard duplex stainless steels.

Super Duplex F53 Orifice WN BL SO SW Flange, ANSI B16.5 Super Duplex Stainless Steel S32750 Orifice Flange, Super Duplex F53 WN Flange, Super Duplex Steel S32750 Pipe Flanges, Super Duplex Steel S32750 Flanges, Super Duplex F55 Spectacle Blind Flanges

Super duplex forged flanges made of S32750 (also known as A182 F53) offer several key features and characteristics. Here are the main features of super duplex forged flange S32750 A182 F53:

1. Corrosion resistance: ANSI B16.5 Super Duplex Stainless Steel S32750 Orifice Flange provides excellent resistance to a wide range of corrosive environments, including seawater, acidic solutions, and chloride-containing environments. Super Duplex F53 WN Flange exhibits higher corrosion resistance than standard duplex stainless steels.

2. Strength and toughness: Super Duplex F53 Orifice WN BL SO SW Flange offers high tensile strength and superior toughness, making Super Duplex Steel S32750 Flange suitable for demanding applications where strength and durability are required.

3. Duplex microstructure: The microstructure of Super Duplex Steel S32750 Flange consists of an equal mixture of austenite and ferrite phases. This duplex structure contributes to its enhanced mechanical properties and corrosion resistance.

4. High-pressure and high-temperature resistance: Super duplex forged flanges made of S32750 A182 F53 can withstand high-pressure and high-emperature environments, making Super Duplex F55 Flange suitable for applications in oil and gas, petrochemical, and offshore industries.

5. Weldability: Super Duplex F53 Slip On Flange exhibits good weldability and can be easily welded using common welding techniques, such as TIG or MIG welding. However, preheating and post-weld heat treatment may be required to maintain the desired properties and prevent sensitization.

6. Pitting and crevice corrosion resistance: UNS S32750 Super Duplex Flange offers excellent resistance to pitting and crevice corrosion, which are common types of localized corrosion that can occur in harsh environments.

7. Resistance to stress corrosion cracking (SCC): SCC is a type of corrosion that can occur in the presence of tensile stress and specific corrosive environments. Super Duplex Steel S32750 Threaded Flange demonstrates good resistance to stress corrosion cracking, providing added reliability in critical applications.

8. Machinability: Although Super Duplex F53 Weld Neck Flanges are generally more challenging to machine compared to austenitic stainless steels, S32750 can be machined using appropriate techniques and tools.

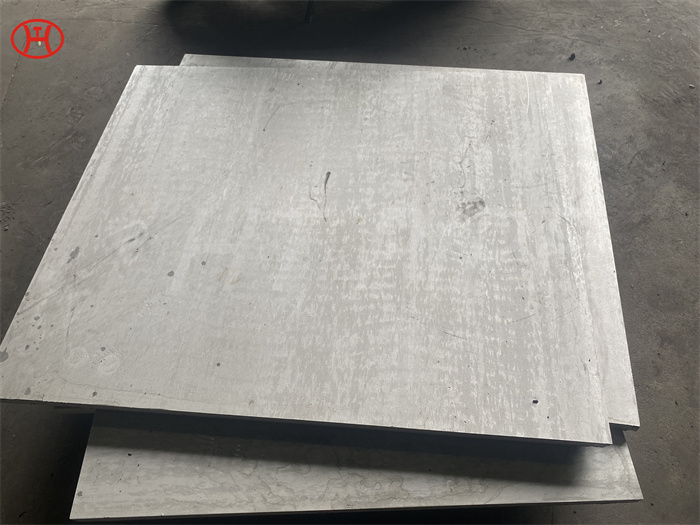

Super Duplex Steel S32750 / S32760 Pipe Flanges Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

Super Duplex Steel S32750 / S32760 Plate Flanges Mechanical Properties

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 | 7.8 | 0.281 | 1350 | 2460 |