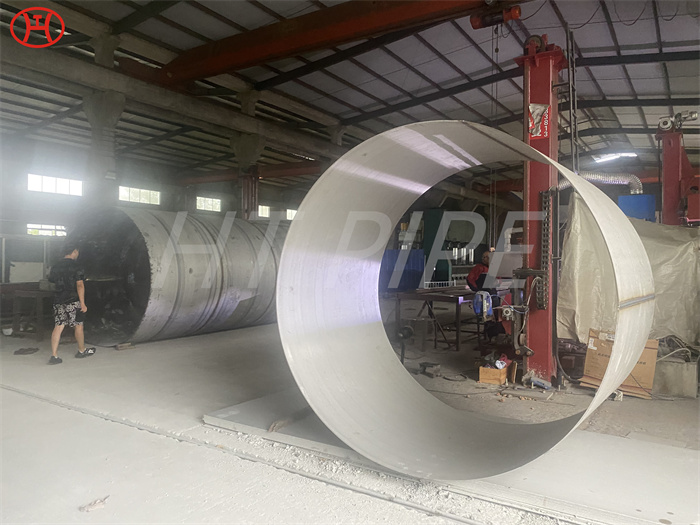

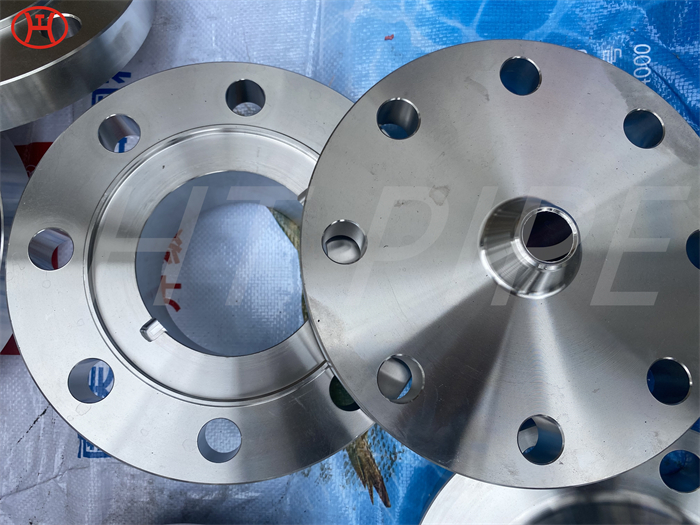

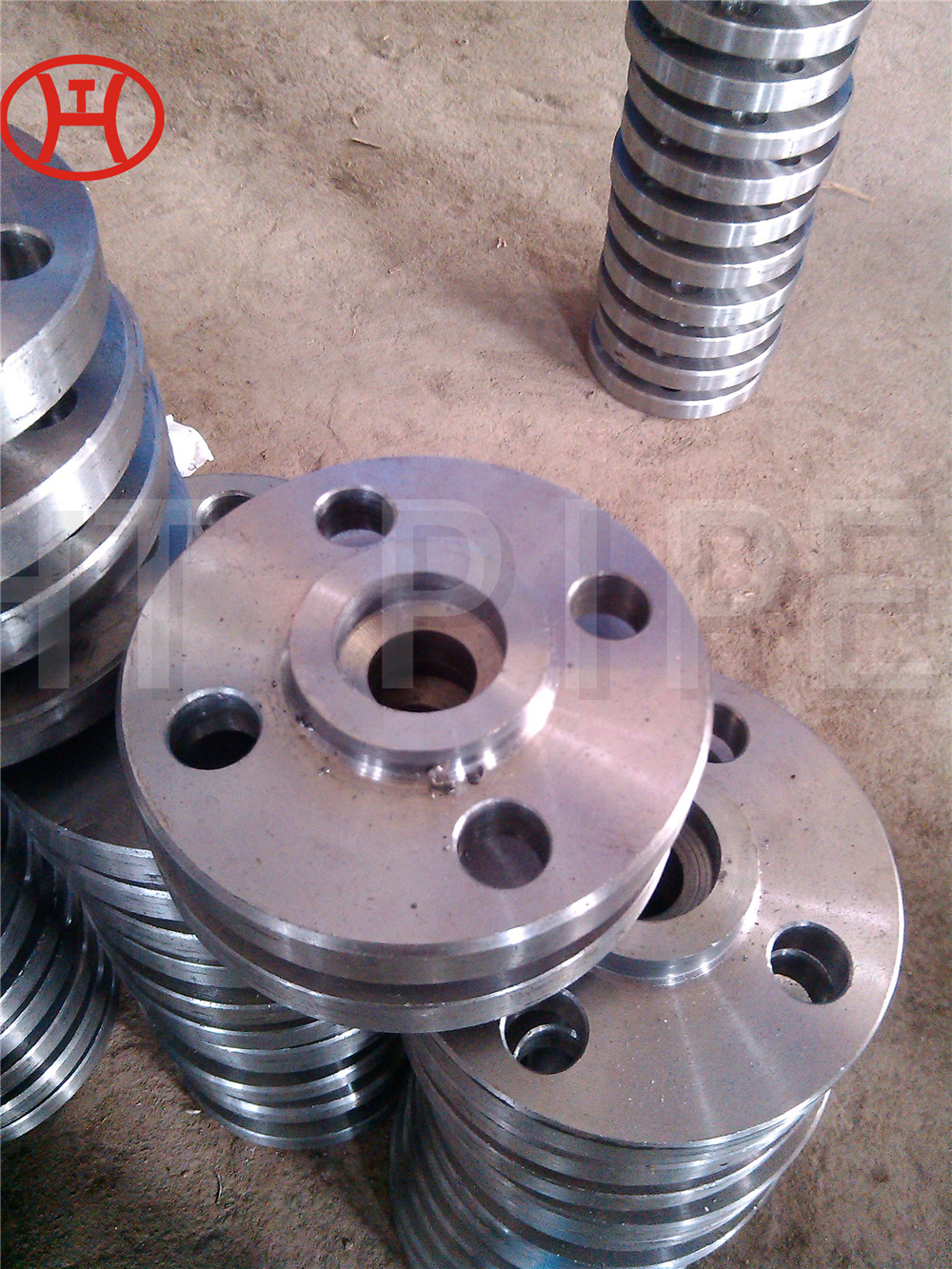

Super Duplex S32750 Flange used for Chemical Piping systems

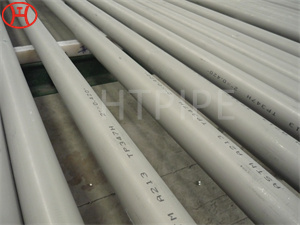

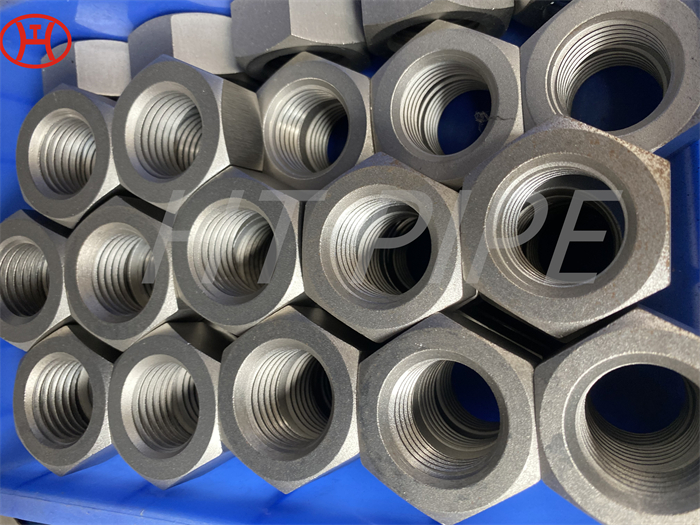

The material has high strength and corrosion resistance. The A182 F53 material is used to make flanges ranging from 1/2 inches to 48 inches under different standards such as ANSI, ASME, DIN and other international standards.

Super Duplex Steel S32750 Weld Neck Flanges are also being offered in different sizes and shapes to our customers. Because our Super Duplex Steel S32760 Blind Flanges is substantially better than either SS 316L or SS 904L in this situation, it is a good candidate for wet process phosphoric acid applications. The higher molybdenum and chromium content of Super Duplex UNS S32750 Plate Flanges gives it the ability to resist corrosion in an enhanced manner. The Super Duplex 2507 S32750 Blind Flanges have greater resistance against pitting and crevice corrosion than a standard duplex or austenitic steel. Super Duplex Steel S32750 Flanges exhibit a mixed austenitic and ferritic microstructure. The key difference is that these flanges contain more chromium and molybdenum. Compared to standard grades, this provides better corrosion-resistant properties. It possesses a dual-phase microstructure that combines high strength with cost-effective corrosion resistance, specifically in chloride-rich settings.