Super duplex steel 1.4410 S32750 F53 2507 Hex Nut DIN934 manufacturer

2507 nuts are highly resistant to carbide-related intergranular corrosion due to their low carbon content (0.020% in weight).

Super Duplex 2507 nuts (EN 1.4410) are made of a stainless steel alloy containing 25% chromium, 4% molybdenum, and 7% nickel. Duplex 2507 nut is known for its high strength and excellent localized corrosion resistance to chloride. The 2507 nut is widely used for its yield strength which is twice that of annealed austenitic stainless steels, like 304 and 316 stainless.

2507 nut is designed to handle highly corrosive conditions and situations were high strength is required. High molybdenum, chromium and nitrogen content in Super 2507 nut help the material withstand pitting and crevice corrosion. The 2507 nut is also resistant to chloride stress corrosion cracking, to erosion corrosion, to corrosion fatigue, to general corrosion in acids. This duplex steel has good weldability and very high mechanical strength.

Stainless Steel Alloy 2507 nut is stocked by 39 North American distributors and produced by 22 large mills. Distributors will offer small quantity buys while mills will generally only sell large quantities, with delivery times anywhere from 10 to 50 weeks depending on size and form required.

Chemical Composition

The chemical composition of stainless steel grade Super Duplex 2507 is outlined in the following table.

| Element | Content (%) |

|---|---|

| Chromium, Cr | 24 – 26 |

| Nickel, Ni | 6 – 8 |

| Molybdenum, Mo | 3 – 5 |

| Manganese, Mn | 1.20 max |

| Silicon, Si | 0.80 max |

| Copper, Cu | 0.50 max |

| Nitrogen, N | 0.24 – 0.32 |

| Phosphorous, P | 0.035 max |

| Carbon, C | 0.030 max |

| Sulfur, S | 0.020 max |

| Iron, Fe | Balance |

Physical Properties

The physical properties of stainless steel grade Super Duplex 2507 are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.8 g/cm3 | 0.281 lb/in3 |

| Melting point | 1350°C | 2460°F |

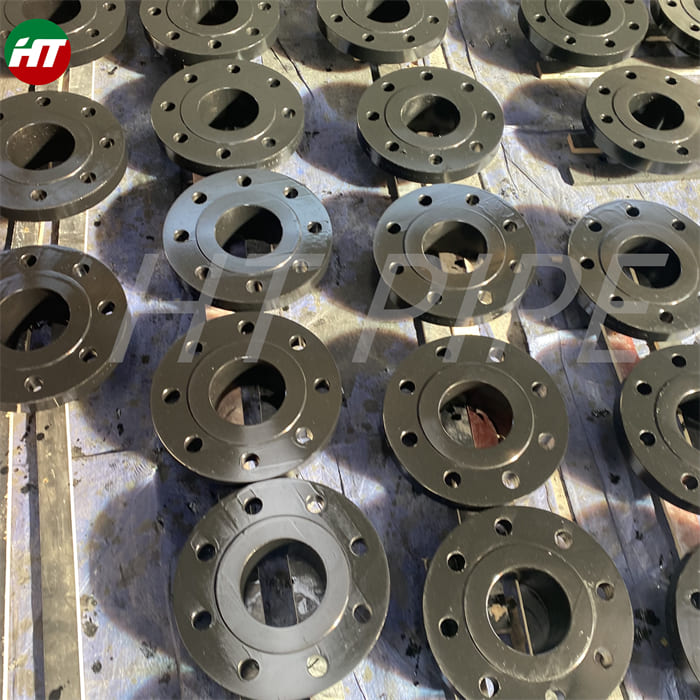

Applications

Super Duplex 2507 is widely used in the following sectors:

- Power

- Marine

- Chemical

- Pulp and paper

- Petrochemical

- Water desalinization

- Oil and gas production

Products made using Super Duplex 2507 include:

- Fans

- Wire

- Fittings

- Cargo tanks

- Water heaters

- Storage vessels

- Hydraulic piping

- Heat exchangers

- Hot water tanks

- Spiral wound gaskets

- Lifting and pulley equipment

- Propellers, rotors, and shafts