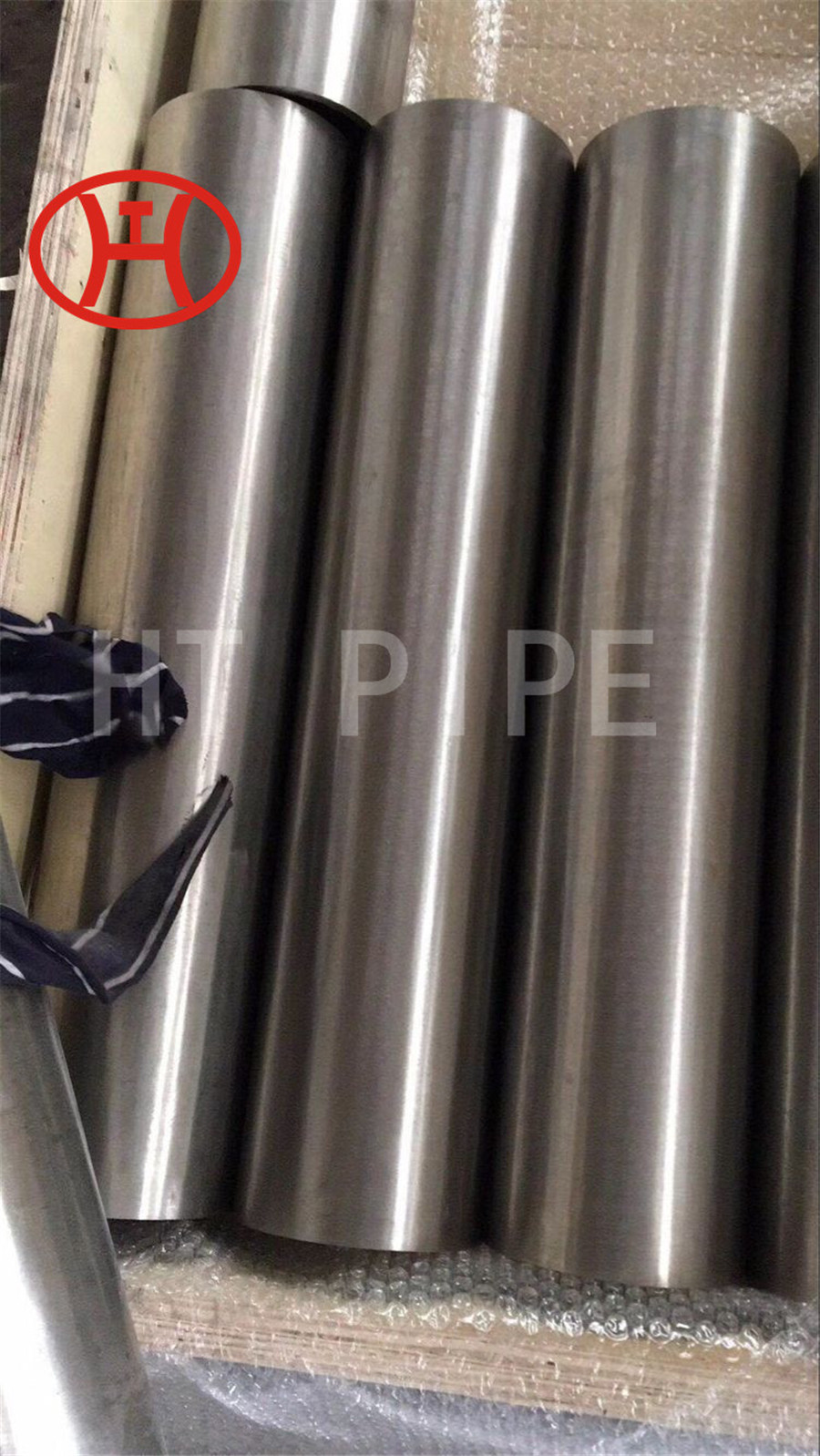

Suppliers of ASTM A409 SMO 254 Seamless Pipes

SMO 254 Hallow Pipes is considered resistant to potable water with up to about 200 mg / L chlorides at ambient temperatures, reducing to about 150 mg / L at 60 Degree C.

ASTM A213 Uns S31254 Seamless Tube, ASME SA213 SCH40 Alloy 254 Square and Rectangle Pipe

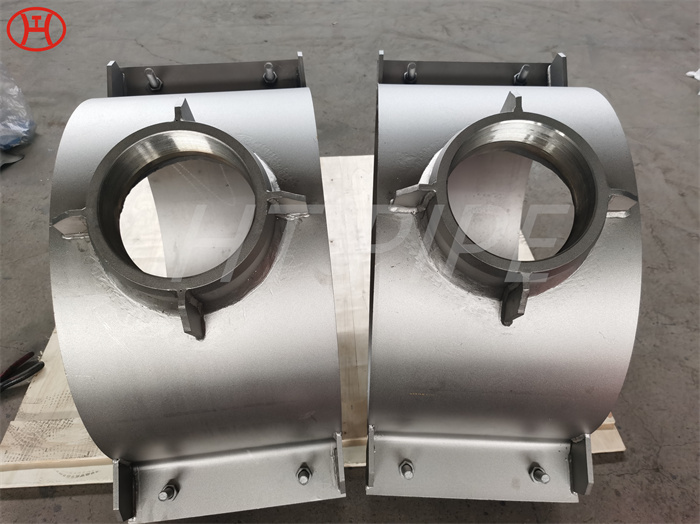

HT 254 Smo Pipe are available in ATSM B163/ B167, AMS 5580, BS3074 specifications. Sandvik 254 Smo Tubing can also be customized as per specific client requirements. 254 Smo Tubing has a tensile strength of 98,600 psi 680 MPa. Whereas the yield strength of 6mo Efw Tubing 43,500 psi 300 MPa. We at Victor Steel strive to provide our clients with the best quality of product and customizes the 254 Smo Pipe Sizes according to their requirements.

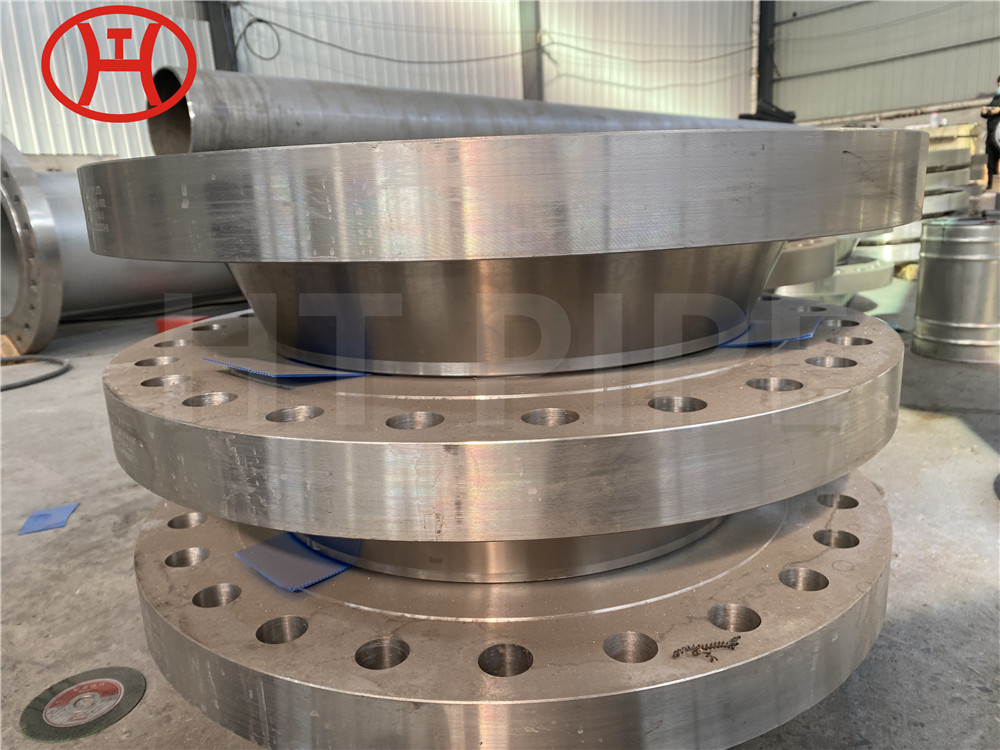

Steel is available in ferritic and austenitic grades. 254 SMO Pipes are austenitic types of pipes which is twice as strong as regular stainless steel. Astm A312 Uns S31254 is considered to be a cost-effective substitute for high titanium and nickel alloy. Uns S31254 pipe is resistant to pitting and crevice corrosion and also has a strong resistance to chloride stress corrosion cracking. 254 Smo Seamless Pipe is used in petroleum production, saltwater handling, and food processing industries. ASME SA213 SCH40 Alloy 254 tubes are also used in the pulp and paper industry in bleaching equipment. Yet, even the presence of about 3.5% salt is enough to corrode conventional steel alloys.

However, because of the higher content of alloying in 254 SMO seamless pipe, the rate of corrosion is significantly lower. Volcanic activity or the presence of any heat source could instantly increase the temperature of seawater. Heat in combination with a high level of sodium chloride accelerates the rate of decay in traditional alloys as opposed to ASTM A312 UNS S31254 6 moly welded pipes. Hence, in many countries across the world, SMO 254 Pipe manufacturers recommend using this alloy because it can withstand corrosive marine environments, without any visible decay on its surface. With the content of chromium as high as 19%, the Alloy 254 smo pipe forms a passivated oxide layer, which prevents the alloy from getting decayed by oxidation.

254 SMO Tube Mechanical Behaviour

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

Chemical Structure Of 254 Smo Seamless Pipe

| SMO 254 | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

If you are a Spanish user, you can visit this website:https://www.htpipe.es/tuberias-tubos-de-acero-inox-s31254.html