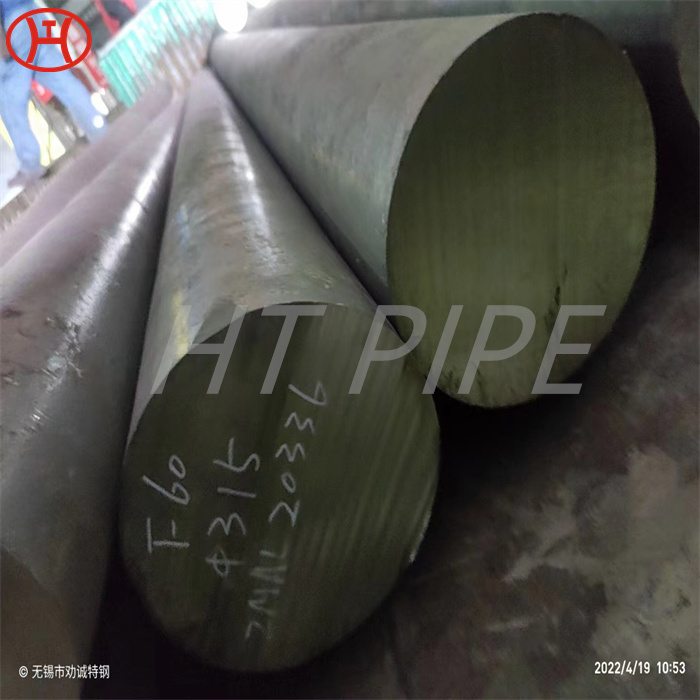

The photo of PMI test of incoloy 825 round bar

Incoloy is a group of superalloys mainly made of nickel, iron and chromium. They are designed for corrosion resistance and high creep and rupture properties. Incoloy 825 round bar uses additional copper and molybdenum.

Standardized version ASTM B425 UNS N08825 Bar has an austenitic microstructure and supports ductility at low temperatures. It has a high melting point range of 1370-1400 degrees Celsius, so it can be used in oil and gas well piping and nuclear fuel reprocessing. UNS N08825 Bright Bar provides a minimum tensile strength of 586 MPa and a yield strength of 241 MPa at room temperature.

Incoloy 825 round bar is designated UNS N08825 and Werkstoff number 2.4858. Alloy 825 round bar is also known as Incoloy 825 round bar, Inconel 825 round bar and Nickel alloy 825 round bar. Alloy 825 round bar has excellent resistance to reducing and oxidizing acids, stress corrosion cracking and localized corrosion such as pitting and crevice corrosion.

Incoloy 825 is a general purpose nickel-chromium alloy. Incoloy 825 round bars are designed with a round cross section for excellent resistance to corrosive and oxidizing media. High-strength alloy 825 forged bar provides protection against localized attack due to crevice corrosion and acid pitting in different systems. Multifunctional alloy 825 round bar can be cold rolled or hot rolled and can work in high temperature environment.