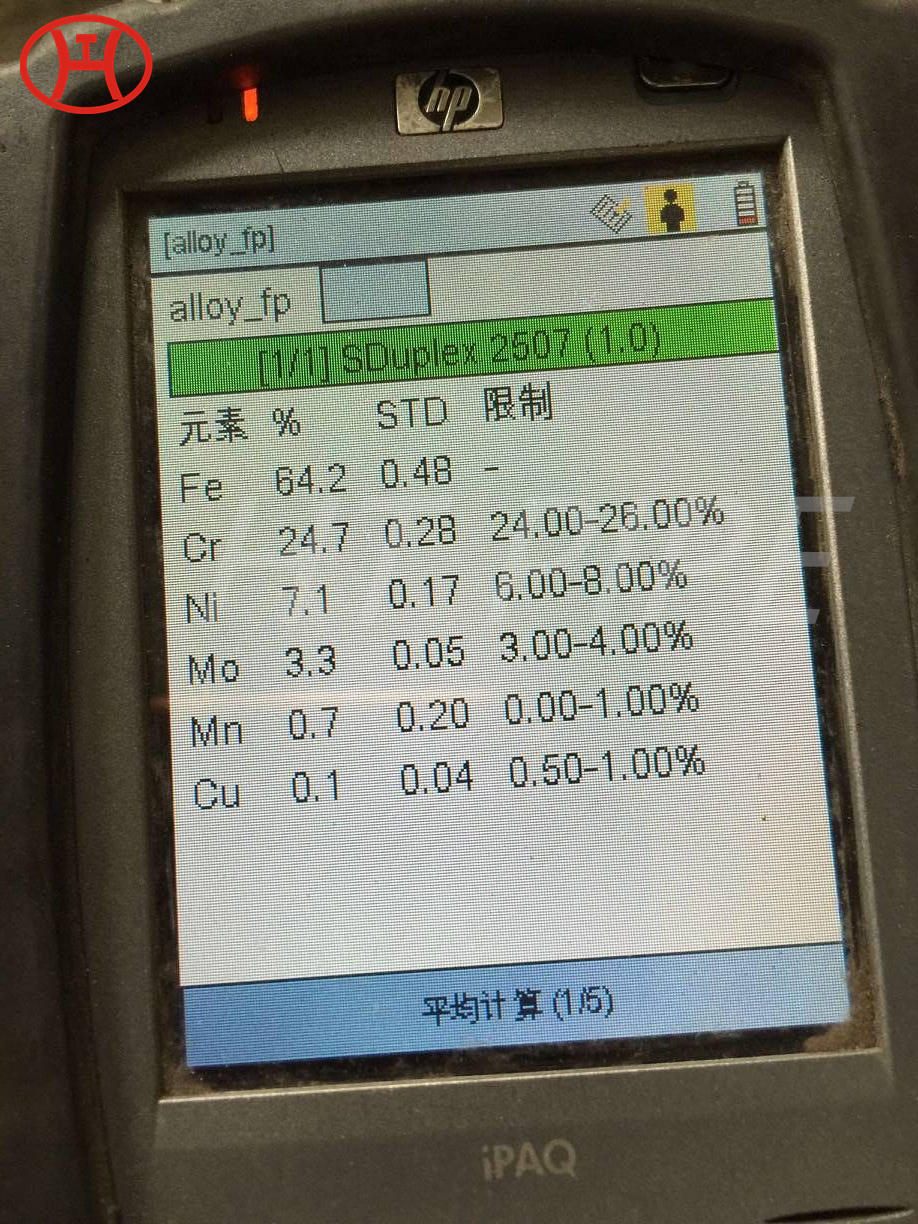

The photo of PMI test of S32750 round bar

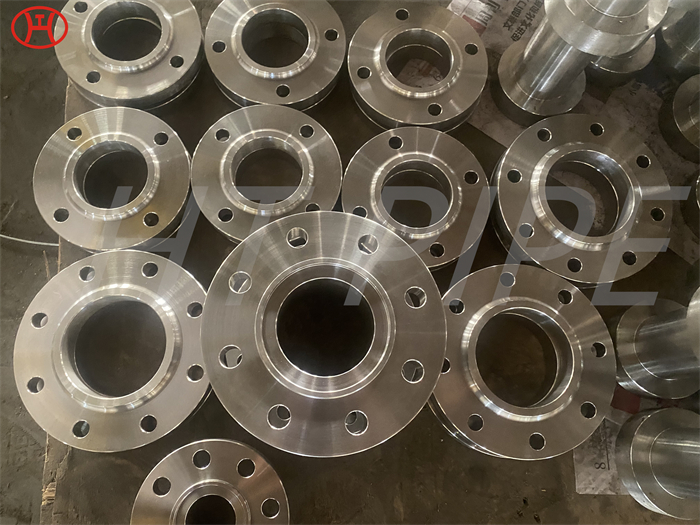

Super Duplex 2507 is designed to handle highly corrosive conditions and where high strength is required. The high molybdenum, chromium and nitrogen content in Super Duplex 2507 helps the material withstand pitting and crevice corrosion.

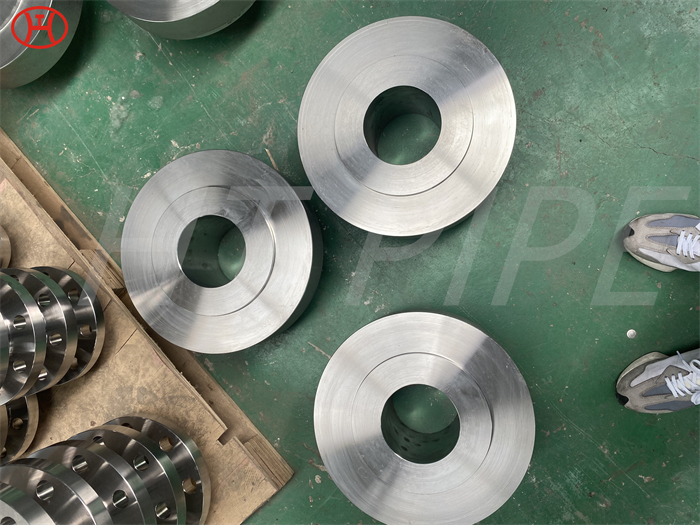

Alloy 32750 is known as a super duplex stainless steel and is supplied to manufacturers in the annealed condition. As a super duplex steel, this alloy combines various desirable aspects and characteristics of austenitic and ferritic stainless steels. In addition, high levels of molybdenum, chromium and nitrogen contribute to the alloy’s excellent resistance to crevice and pitting corrosion. Due to its outstanding properties and properties, this material is used in numerous industries for the manufacture of different components.

The material is also resistant to chloride stress corrosion cracking, erosion corrosion, corrosion fatigue and general corrosion in acids. This alloy has good weldability and very high mechanical strength.

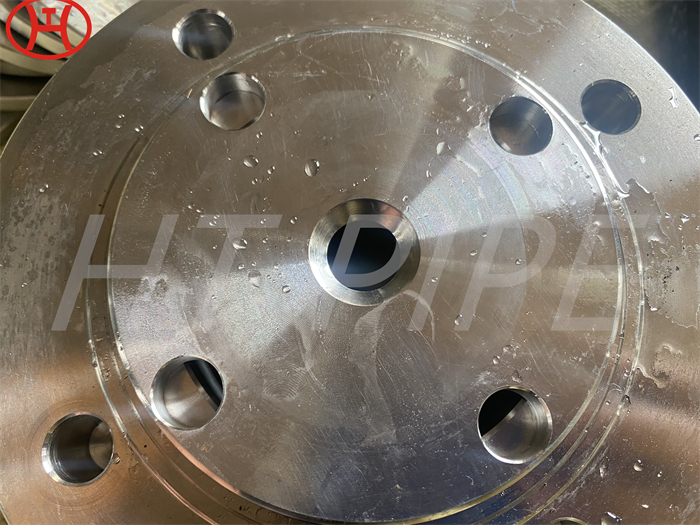

The combination of austenite and ferrite in the microstructure of ASTM A276/A479 UNS S32750 round steel gives it unique high strength and excellent corrosion resistance with good impact resistance. Impact resistance or toughness is a required property in industries dealing with structural products, especially in equipment manufacturing.